Nutrition is one of the keys to achieving optimal livestock performance. The nutritional needs of livestock are met mostly from feed. In addition, feed is holding the largest portion of the cost in maintenance that reaches 70-85%. This can be one of the strategies of farmers in streamlining maintenance costs, namely by starting to focus on feed cost efficiency.

The demands of efficiency in feed costs encourage some farmers began to do self mixing (mixing their own feed), with the main purpose of reducing feed costs. However, it should be noted that self mixing it has its own advantages and disadvantages.

Some advantages self mixing among other things, the cost of feed is relatively cheap, the nutritional content can be adjusted, flexible in selecting raw materials, so as to optimize the potential of available local raw materials. While the lack of self mixing the quality of the raw materials and the quantity of raw materials fluctuate, need additional investment in infrastructure (mixer, warehouse), test feed and its formulation and additional labor.

Quality Feed

Chicken performance modern increasing with the level of feed efficiency is getting better. Quality feed is a solution in achieving good feed efficiency. Quality feed is also one of the determinants of livestock productivity.

To produce quality feed that must be considered is first, smart and careful in choosing raw materials by paying attention to the requirements of quality raw materials. Second, the calculation of the right formulation according to the actual condition of livestock. Thirdly, it needs to be accompanied by good quality control. Quality feed that is also supported by good feed management will result in more optimal livestock performance.

Choosing Poultry Feed Ingredients

Feed ingredients are raw materials used to prepare a feed formulation. Classification of poultry feed ingredients are divided into several categories such as based on nutrient content (energy sources, protein sources, mineral sources and premixbased on its source (vegetable and animal) and based on its origin (main product and by product).

a. Based on nutrient content

1. Energy sources

Energy source feed ingredients are feed ingredients that contain energy of at least 2,250 kcal/kg. Examples: corn, bran, CPO, Groats.

2. Protein sources

Protein source feedstuff is a feedstuff that contains high protein of ③ 20%. Example: soybean meal, meat bone meal, fishmeal.

3. Mineral resources

Mineral source feed ingredients are feed ingredients that only contain high minerals. Example: flour or stone grit, dicalcium phosphate (DCP), monocalcium phosphate (MCP).

4. Premix

Premix it is a feed ingredient that is added in small amounts to improve feed quality. Premix can be feed supplement, feed additive or a combination of both. Examples feed supplement namely amino acids, minerals (such as Mineral Feed Supplement Ayam, Endomixvitamins (such as Top Mix HC, Mix Plus PG, Mix Plus PGA and Mix Plus PS). While feed additive the enzyme (Betterzym, Prozyme), toxin (Freetox, Freetox-G), mold inhibitor (Fungitox), phytobiotics (Optigrin). As well as variations premix complete like Mix Plus BAP3A, Mix BAM23A or Mix Plus Bro BAP12A for broilers and Mix Plus LLM3A or Mix Plus LLM3B for laying hens.

Some types of feed ingredients can fit into more than one category such as distiller’s dried grains with solubles (DDGS). This is because DDGS contain high energy and high protein, so DDGS can be used as a feed source of energy and protein at the same time. Categories of feed ingredients based on the nutrient content, each should be present in the feed formulation components so that nutritional targets can be achieved.

b. Based on the source

1. Vegetable

Vegetable raw materials are feed raw materials whose basic ingredients come from plants, especially grains, for example corn, wheat, soybean meal, Bran, etc.

2. Animal

Animal raw materials are feed raw materials whose basic ingredients come from animals such as meat bone meal, fish meal, bone meal, etc.

In the formulation of feed combinations of feed ingredients based on the source, both should exist for mutual substitution of nutrient content, especially related to the amino acid profile.

c. Based on its origin

1. Main product (main products)

Feed ingredients whose basic ingredients are the main commodities (not waste) such as corn or stone flour.

2. By-Product (processing by-products)

Feedstuffs, the basic ingredients of which are by-products of the processing of certain products (waste), for example, Bran, soybean meal, meat bone meal.

Most of the animal feed comes from by-product (processing byproducts). So the quality can fluctuate depending on the processing time. In addition, the quality of feed raw materials can also be affected by several other factors such as high moisture content, mold and mycotoxin growth, flea contamination, counterfeiting, etc.

Feed quality is influenced by the quality of feed ingredients. Low-quality feed leads to a decrease in livestock performance and entails losses for the farmer. Therefore, it is important for farmers to always be smart and careful in choosing quality feed ingredients.

Terms Of Quality Feed Ingredients

In the field, the quality of feed ingredients is often varied. This is one of the obstacles in the formulation of feed. And if it is still used in the formulation, it can reduce the quality of the feed. So that farmers should appropriately consider its use in the formulation and treatment that can be done. In choosing the feed ingredients used in the formulation should consider some of the requirements of quality feed ingredients as follows :

1. Nutrient content according to standard

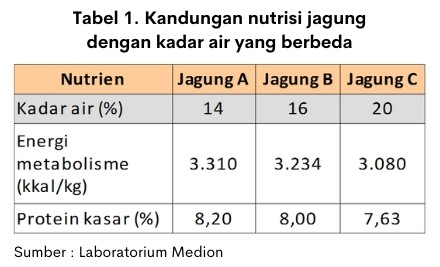

Pay attention to the content of nutrients should ideally match the standards. One of the determining parameters of the nutrient content of feedstuffs is moisture content. The water content will be inversely proportional to the dry matter content. The dry matter content is what describes the nutritional content.

So the higher the water content, the lower the dry matter content. So the nutritional content of feed ingredients is also getting lower. Example Table 1. shows the quality of corn with different moisture content so that it decreases the nutrient content as the moisture content of corn increases.

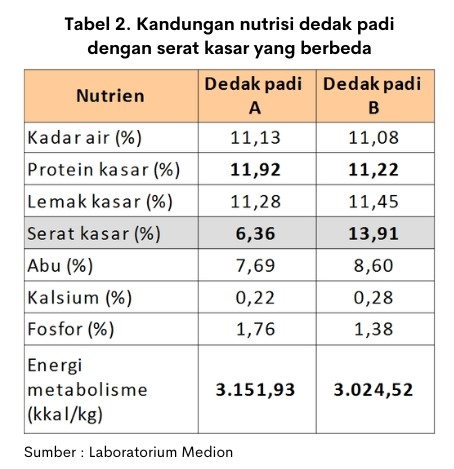

In addition, the high content of coarse fiber can also reduce the quality of the nutrient content. Example Table 2. showed differences in crude fiber content in rice bran thus reducing nutrient content.

2. Low antinutrients

Antinutrients are known as limiting factors for the use of raw materials in feed formulations. When the antinutrient content is high in feed ingredients, it can reduce the digestibility of the feed. The mechanism of action of antinutrients will bind nutrients that should be digested and absorbed by livestock.

Types of antinutrients in feed ingredients include phytic acid, non starch polysaccharida (NSP), protease inhibitor, etc. Examples of phytic acid content in rice bran will bind minerals, especially phosphorus. Thus, reducing the digestibility of phosphorus which has an impact on bone growth is disrupted, the quality of eggshells also decreases. The solution to minimize the content of antinutrients is by adding feed additive enzymes such as Betterzym or Prozyme. The addition of this enzyme is able to increase the digestibility of feed nutrients in the gastrointestinal tract.

3. High digestibility

Pay attention to the digestibility of raw materials because certain raw materials that contain high nutrients (such as crude protein), can be when consumed by livestock low digestibility. Thus, the nutrients that can be absorbed by livestock are also low. Examples of feather flour protein content can reach 90% twice as high compared to soybean meal 45% (lin et al., 2001).

However, this fluff flour has low digestibility due to the presence of keratin content. Generally, fur flour that can be used in the formulation is fur flour that has been hydrolyzed so that it can be digested by livestock well.

4. High palatability

Palatability or likability of cattle will correlate with feed intake. The palatability of the feed can generally be influenced by the color and aroma of the feed. The light color of the feed is usually because it is dominated by corn components. This makes the bright color of the feed preferred by chickens. On the contrary, when the color of the feed is dark, it is less preferred by chickens.

5. Continuous availability

The ideal quantity of feed ingredients is the amount of availability must be continuous. This is to avoid the occurrence of feed exchanges that cause livestock stress, resulting in an impact on the decline feed intake.

To get around the fluctuating availability of feed. Farmers can carry out stock storage of feed ingredients accompanied by long storage and proper management, so that the quality of feed ingredients is maintained. In addition, maximizing the potential of local feed ingredients available in abundant and continuous quantities, can also be an alternative solution and save logistics costs in the delivery of feed ingredients.

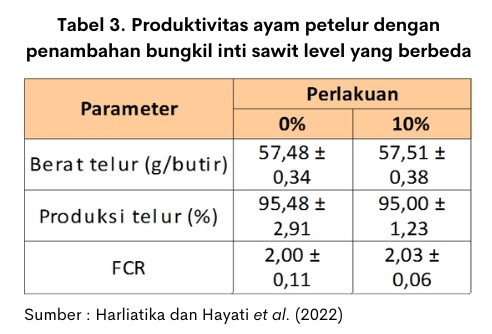

Some familiar local raw materials are used by farmers such as palm kernel cake as a source of protein. Harliatika and Hayati et al. (2022) in his research, using palm kernel meal of 0% and 10% and the addition of multienzymes did not interfere with the productivity of laying hens aged 40-50 weeks.

So that the use of local raw materials such as palm kernel cake can be an alternative solution in producing quality feed. Here's Table 3. the productivity of laying hens fed with palm kernel meal with different levels showed no significant difference.

Proper feed formulation

Smart and careful in choosing the components of raw materials is not enough, without being equipped with the proper calculation of the formulation. Here are some parameters of success in feed formulation, among others:

a. Precision formulation

Precise formulation based on nutritional requirements real livestock in the barn is to pay attention to strains, phase or age, feed consumption rate, enclosure environment and livestock health status. In addition, the feed ingredients used in database formulation calculations are the actual feed ingredients available and their nutritional content.

So ideally before the feed ingredients are calculated in the formulation, it is necessary to test the nutritional content first. When after mixing into feed, the nutritional content is tested again to find out whether it is in accordance with the needs of livestock. So that the formulation prepared will be precise and precise to support optimal performance.

b. Competitive price

Feed formulation is targeted to be able to achieve competitive prices. So the nutritional content is achieved according to the target and the price achieved can be as cheap as possible (least cost formulation). With a note without prejudice to the quality of feed should also be good. To make it easier to cook at least cost formulation can resort to the help of the application of formulations such as brill formulation, winfeed, etc.

c. Nutrition Target achieved

As a formulator, it must be able to combine various sources of feed ingredients with the right composition for use. In addition, pay attention also to the limits of the feed ingredients used. Both of these are important to be applied when calculating feed formulations to achieve proper and balanced nutrition targets.

d. High palatability

Quality feed is not only nutritionally balanced and complete. However, quality feed pays attention also to the level of palatability by livestock. This is so that the feed that has been made can be consumed properly by livestock.

e. Optimal productivity

The right formulation is the key to producing quality feed. Feed quality is evaluated through livestock productivity. To produce optimal productivity needs of macro and micro nutrients must be fulfilled in the formulation of feed. Macronutrients are mostly supplied from the use of raw materials, while micronutrients are mostly supplied from the addition of premix.

Additions premix also acts as back up nutrition when the quality of feed ingredients is poor and volatile. Additions premix like Top Mix or Mix Plus complete contains micro nutrients such as minerals, vitamins, amino acids and content feed additive like alternatives egg promoter or growth promoter, enzymes, toxin can help optimize livestock productivity.

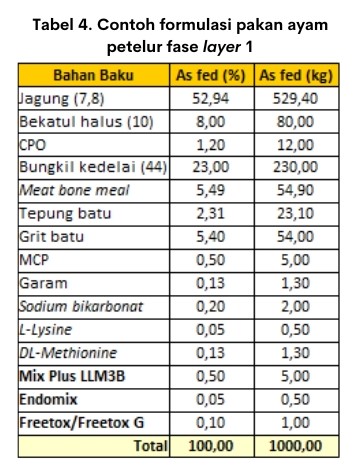

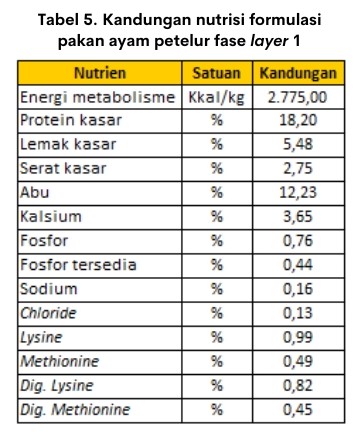

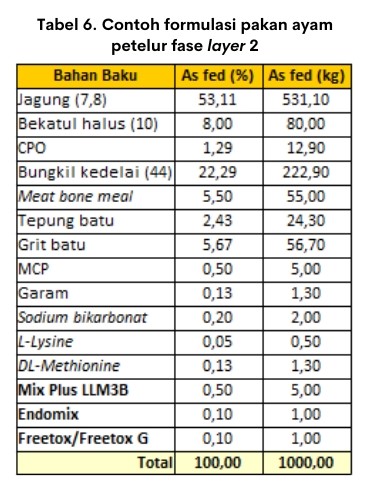

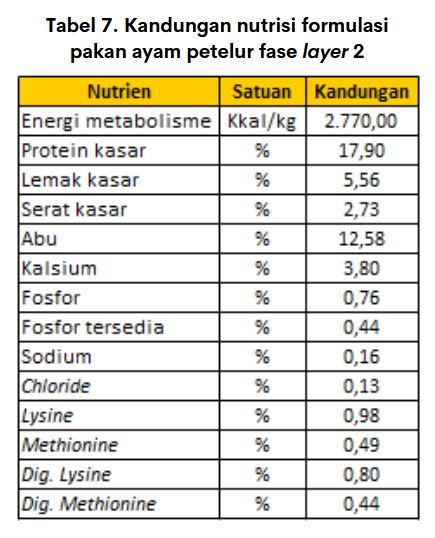

The following is an example of a phase laying hen feed formulation layer 1 (Table 4) and phase layer 2 (Chart 6). Pay attention to the needs between the different phases is a critical point in the preparation of the right formulation.

The above formulations can be used for Phase laying hens layer 1 that is, 2% begin to lay eggs until the age of 55 weeks.

The above formulations can be used for Phase laying hens layer 2 is the age of 55 weeks to reject.

Importance Of Quality Control

Quality control becomes a part that cannot be released in a process to produce quality feed. This quality control should be carried out on all production process lines, starting from the receipt of raw materials, during the production process and the resulting feed.

Quality control can be carried out by several methods. Physical method (organoleptic, specific gravity test) and chemical method (practical chemical test and laboratory test). Practical chemistry test such as using test Phlorotest, while laboratory tests can be performed in Medion laboratories (MediLab).

By utilizing the potential of feed ingredients based on quality and quantity, followed by proper formulation and accompanied by good quality control. So as to produce quality feed to support optimal livestock performance. May be useful.