Based on predictions from BMKG, the beginning of the rainy season in Indonesia varies, starting from the Western Region of Sumatra which entered the rainy season earlier in August 2024. As for the eastern Indonesia region in January to February 2025.

So in general, most parts of Indonesia will experience the rainy season in the period from October to November 2024. Transition rainy season is a challenge for farmers against monitor the quality of feed ingredients and feed used, especially in vegetable source feed ingredients derived from plants.

On the other hand, the risk of fungal and mycotoxin contamination can increase, because a more humid environment becomes a comfortable condition for fungi and mycotoxins to easily grow.

Mycotoxin detection in the field

In the field, fungal contamination of feed or feed ingredients can be easily seen directly, but for mycotoxins (fungal toxins) can not be seen directly. This makes mycotoxins known as hidden enemies for farmers.

To detect mycotoxin contamination in feed and feed ingredients, it needs to be supported by sample testing, either through qualitative or quantitative methods. Test sampling must also be carried out with appropriate methods that are homogeneous and representative. This is related to the nature of mycotoxins that spread at certain points on contaminated feed or feed ingredients. Appropriate sampling methods can determine the amount of mycotoxins that can be detected.

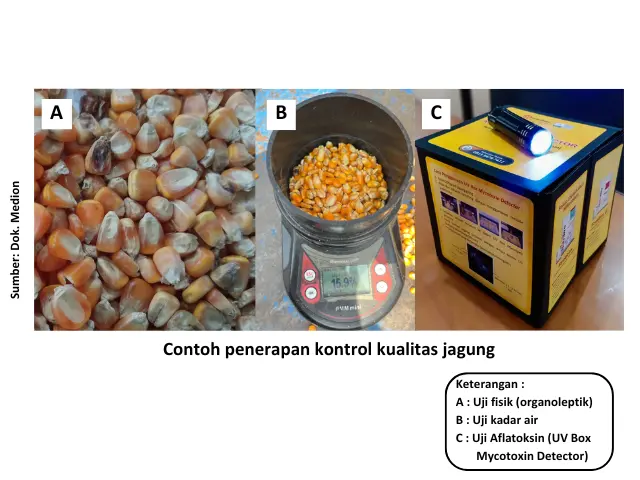

In a qualitative method, to detect the presence or absence of aflatoxin type mycotoxins in feedstuffs such as corn, farmers can test using UV Box Mycotoxin Detector. The trick, corn samples are coarsely ground first, then placed in a black box and highlight with a lamp/flashlight ultra violet (UV). Corn that looks fluorescent (purplish green) indicates that it has been contaminated with aflatoxins.

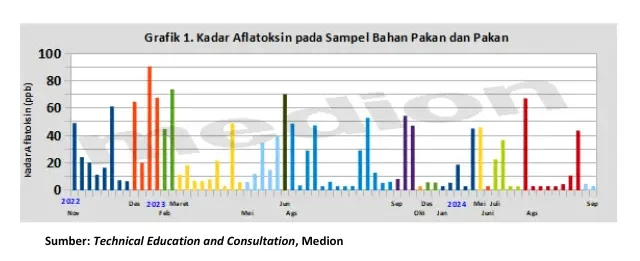

In quantitative methods, farmers can test samples of feed ingredients or feed to the Medion laboratory to find out how many levels (ppb) of aflatoxin in it. Here's the data monitor aflatoxin levels in the field tested in the Medion Laboratory (Graph 1).

When the rainy season arrives, farmers are difficult to find feed ingredients, especially corn with low moisture content. The moisture content determines the storage time in the feed warehouse, which is ideally less than 14%. Especially when the intensity of rain is high, the handling of post-harvest corn, especially on farmers who still take advantage of the sun's heat, is difficult to reduce its water content.

In addition, poor feed storage management factors also trigger the growth of fungi and mycotoxins. Increased humidity and the presence of rainwater tampias in the cage are also comfortable conditions for the fungus to grow easily.

Impact of fungal and mycotoxin contamination

1. Lowering feed quality

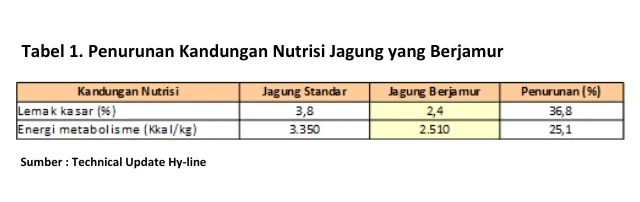

Fungal and mycotoxin contamination can lead to a decrease in feed quality. As well as in moldy corn nutritional content has decreased, the amount of decline is influenced by the amount of fungal contamination in the feed or feed ingredients.

The more fungal contamination, the more nutrient degradation. It is related that the fungus needs nutritional intake to develop so that it uses the nutritional content of feed ingredients or contaminated feed. The following is an example of a decrease in the nutrient content of standard corn compared to moldy corn (Table 1).

In addition, feed ingredients or feed that has been moldy will produce fungal toxins (mycotoxins). The properties of mycotoxins in feedstuffs and feed are relatively stable compared to fungi, whereby fungi can decrease if exposed to high temperatures (heating).

The level of mycotoxin contamination needs to be considered especially in the most sensitive livestock such as poultry and pigs. There are 5 types of mycotoxins commonly found in feed or animal feed, namely aflatoxin, ochratoxin, trichotesene, zearalenon, and fumonisin. Mycotoxin contamination mostly occurs in combination or more than one type of mycotoxin in it. So it is important to pay attention to the type toxin which will be used to be able to bind the mycotoxin.

2. Decreased livestock productivity

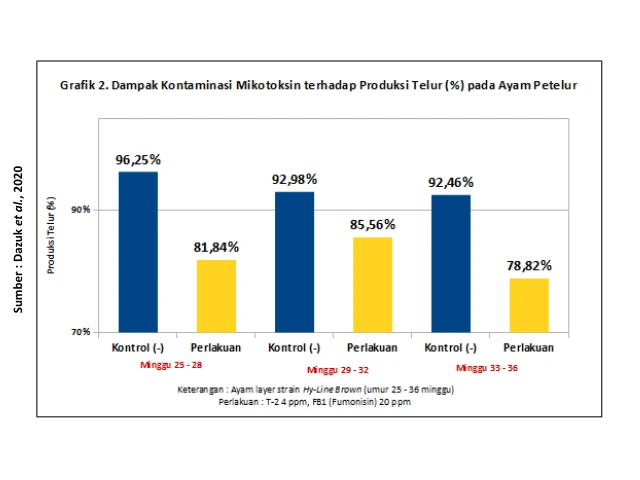

Mycotoxin contamination in livestock causes a decrease in feed consumption so that nutritional needs cannot be met. In addition, mycotoxins can also cause inflammation of the gastrointestinal tract and inhibit the growth of intestinal villi (Anas et al., 2020), can consequently impair nutrient absorption.

Mycotoxins consumed by livestock will accumulate, then spread to the organs in the body of livestock and cause a negative impact on both production performance and egg quality. In addition, the combination of several types of mycotoxins can also cause more severe effects than a single contamination. The following is an example of the combined impact of mycotoxin contamination on egg production in laying hens (graph 2).

Mycotoxins interfere in the process of intestinal absorption and enzyme production, causing vitamin d₂ and calcium are not absorbed optimally resulting in decreased quality of shellfish such as thin, pale, and easily cracked (broken).

3. Impair the health of livestock

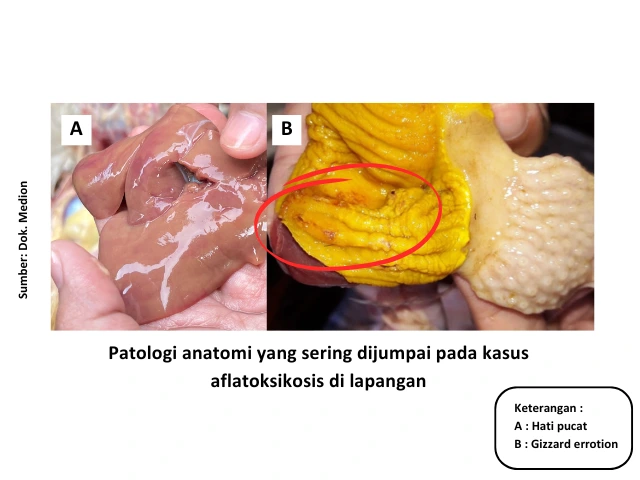

Increasing levels of mycotoxin contamination can cause disruption to livestock health. The impacts on livestock include carcinogenic, teratogenic, neurotoxic, hepatotoxic, or immunotoxic. If necropsy is found some typical anatomical pathalogy depending on the type of mycotoxins that attack such as fragile and pale liver, the presence of gizzard erosion, swelling of the kidneys, hemorrhage in the groin fat, etc.

The severity of the disease can be affected by the condition of the livestock, the duration, the amount of mycotoxin contamination in the body of livestock. Important impact to note that mycotoxins are immunosuppressive (suppress the immune system), so that it can affect the success of vaccination programs and become an opening gate for other diseases to easily enter. Even if it is severe it can lead to death in livestock.

Prevention and treatment of mycotoxin contamination in the field

a. Prevention of mycotoxin contamination

Prevention of mycotoxin contamination in feed or feed ingredients is carried out through approaches from various aspects ranging from post-harvest handling, quality control discipline, storage in feed warehouses, to feed management. When to use feed additive in the feed to cope with fungi and mycotoxins in them.

1. Post-harvest handling

Increased humidity during the rainy season is an obstacle in handling post-harvest corn to produce low moisture content. Especially if the drying process only relies on field conditions (sunlight) only. Therefore, it is necessary to take a step in the right direction, such as using a vacuum cleaner (drying) as well as considering the cost efficiency for drying.

2. Quality control discipline

Choosing the best raw materials is the main goal in quality control, but the constraints in the field of raw material conditions vary and are not stable, especially when the rainy season arrives. Discipline in quality control can minimize the risks posed and actions to overcome them. Stages of quality control starts from the organoleptic test (physical), moisture content, if necessary test the content of nutrients and mycotoxins, especially found the moisture content of raw materials during the rainy season is relatively higher.

3. Proper storage management

During the rainy season, the humidity of the environment in the feed warehouse increases causing the storage of raw materials or feed to be easily overgrown with fungi.

However, this can be minimized with proper storage management, among others, storage in the form of packaging using pallet as a base to avoid moisture directly, pay attention to the distance between the piles and provide a gap between the piles so that there is air circulation, apply the FIFO principle (first in, first outwhen the water level is high, it can be used as a buffer (first expired, first out) to be used first.

If the feed ingredients have been overgrown with fungi and mycotoxins, separate and apply the principle of FCFO (first contamination, first out) and use mold inhibitor like Fungitox to inhibit the growth of fungi. While storage in bulk pay attention to the cleanliness of the base, bulk height and storage duration cannot be too long compared to storage in packaging and lined by pallet. Because storage in bulk is in direct contact with the base layer.

4. Usage toxin quality binder

Minimizing the impact of mycotoxins on livestock can be prevented by the addition of toxin quality. Additions toxin in the feed is able to bind mycotoxins so that they are not absorbed by the body. Mechanism of action toxin it is active in the gastrointestinal tract to bind mycotoxins before circulating through the blood circulation to the target organs, especially the liver, which serves as a detoxification of toxins. Then it will be removed along with feces.

Prevention with use toxin indirectly, it can optimize the digestive process and nutrient metabolism remains optimal. Adequate nutrients and optimal metabolism will increase livestock productivity. Therefore, the use toxin in feed plays an important role in the maintenance of livestock.

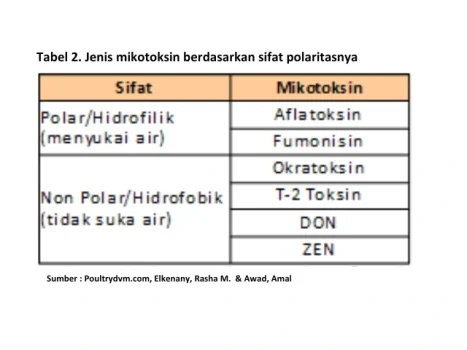

Especially during the rainy season the level of mycotoxin contamination is potentially higher. Types of mycotoxins can be classified based on their chemical and physical properties, including polarity, solubility, molecular size and shape. Especially related to polarity and size, can affect the binding power of toxin used. The following types of mycotoxins are based on their polarity properties (Table 2).

Therefore, not all mycotoxins are the same for easy binding, it is necessary to pay attention to the type of toxin certain to effectively bind it. Types toxin in the field are commonly used inorganic origin such as clay and its derivatives and organic such as yeast. Both have a different and specific ability to bind mycotoxins.

Freetox-G it is a combination of silicate minerals and yeast cell wall which plays a role in binding mycotoxins (fungal toxins), especially aflatoxins strongly. While yeast cell wall it has the ability to bind to mycotoxins through a variety of mechanisms, including hydrogen bonding and hydrophobic interactions.

Therefore, toxin a combination of silicate minerals and yeast cell wall can allow Binding of polar and non-polar mycotoxin types with broad spectrum. In addition, yeast cell wall it can also help in protecting the intestinal membrane and increase the body's resistance. Freetox-G it also contains hepatoprotectors that are able to protect and repair liver cells from damage.

b. Mycotoxin contamination treatment

Handling cases of mycotoxicosis (disease caused by mycotoxins) is different from fungal diseases in livestock that can be given antifungal drugs with certain ingredients. Mycotoxins do not have special drugs, the use of toxin can reduce the accumulative of mycotoxins consumed.

In addition, the administration of multivitamin supplements and liver supplements through drinking water such as Fortevit, Solvit, Strong n Fit, and Heprofit or mixed feed supplements such as Mix Plus and Top Mix HC to repair damaged tissue. Tightens biosecurity and monitor antibody titers because mycotoxins are immunosuppressive.

Thus, at a glance, information related to beware of the dangers of mycotoxins during the rainy season as well as precautions and proper handling.

Efforts to prevent fungal contamination must be applied together starting from farmers, feed makers/ processors, and farmers to avoid the danger of fungal and mycotoxin contamination. So that quality feed and production results and egg quality remain optimal. Hopefully it can add insight to all of us. Success always.