In the development of broiler farming business/broiler currently, the use of closed cages (closed house) indispensable to deal with extreme weather changes and able to eliminate the adverse effects of environmental conditions outside the cage.

In addition, the use of cages closed house needed to maximize production capacity and work efficiency, also environmentally friendly.

Cage closed house it can be used in the open-source environment (open house) especially when the weather conditions are not favorable or the weather changes drastically. Climate change (climate change) that occur today directly or indirectly affect the management of farmers chicken broiler especially in the cage open house.

At the time of extreme weather conditions, namely from very hot heat and then suddenly it rains or vice versa, making the temperature and humidity of the cage change drastically. If not handled properly it can result in high mortality and decreased production.

With the application of the enclosure system closed house then maintenance management will be more appropriate, especially related to the conditions of the microenvironment in the cage. These microenvironmental conditions include :

- Air speed

- Enclosure humidity

- Temperature in the enclosure

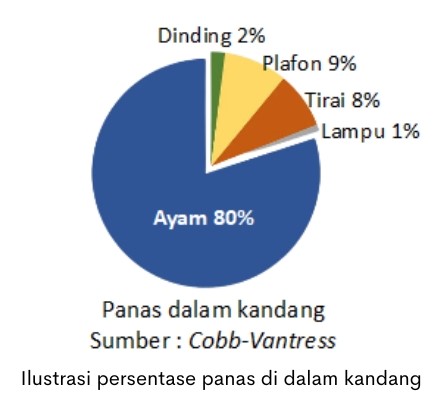

Air velocity is very influential on performance chicken broiler because with the speed of the air will immediately dissipate the heat in the cage. Based on Cobb Vantress 2021 that the heat source in the cage is mostly sourced from the chicken's body (80%), while the rest comes from the heat of the lamp, cage curtain radiation, roof or ceiling, and walls.

Advantages Of Enclosures Closed House

Some advantages of cage closed house include:

- Minimize the influence of environmental conditions outside the cage

- Increase the productivity and performance of chickens broiler

- Controlling temperature, humidity and air speed

- Minimize the impact of environmental pollution (odor and flies)

- Biosecurity more awake

- Health is more assured

- Land efficiency for enclosures

- Labor efficiency

Microenvironment conditions in the cage Closed House

Microenvironment conditions in the cage closed house will greatly determine the performance of the chicken broiler. Chicken performance broiler among other things, it is determined by genetics, nutrition, and the environment and by the implementation of appropriate management. Performance broiler will be more optimal by applying the cage closed house because some parameters of the microenvironment in the cage can be controlled, among others :

1. Air speed

Air velocity inside the cage closed house can be controlled in accordance with the target at any age of maintenance, namely :

- Week 1 : 0.3-0.5 m/s

- Week 2 : 0.5-0.8 m/s

- Week 3 : 0.8-1.8 m/s

- Week 4 to harvest : 1.8-3.2 m / s

With settings inlet and outlet in the ventilation system closed house then the target airspeed can be set. The air speed setting is of course adjusted to the age of chicken maintenance broiler because every age of chicken rearing broiler it has an airspeed limit.

If the air velocity is excess or less it will greatly interfere with the growth of chickens broiler such. The speed of the air in the cage will also determine the effective temperature felt by the chicken. Air speed in accordance with the target needs of chickens broiler will help make the conditions for chickens comfortable and it is noticeable from the consumption of feed and water consumption in accordance with the standards.

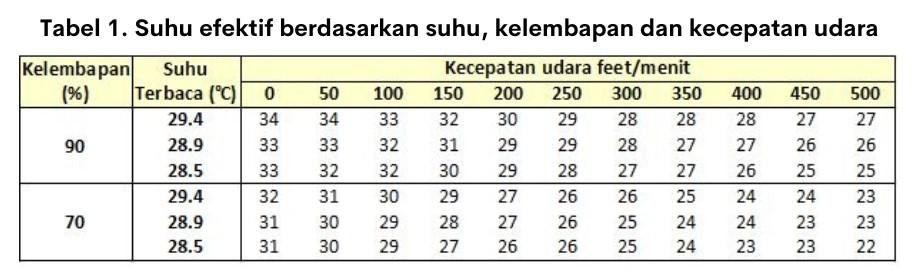

2. Temperature inside the enclosure closed house

The temperature read on the thermometer in the cage closed house actually, it is different from the temperature felt by the chicken's body. The temperature felt by the chicken's body is called the effective temperature. This effective temperature is influenced by 3 factors, namely room temperature (readable temperature), air humidity in the cage, and air flow velocity in the cage. An example of an effective temperature table as in Table 1.

In the care of chickens broiler it turns out that the temperature requirement is different at each age. Target cage temperature in the period starter/brooding period, it can be used as a heating pad (space heater) or spot heater.

Heating system (space heater) will be more efficient for larger capacities because what is heated is the entire room inside brooder. Furthermore, for temperature regulation at the end of maintenance life/finisher what chickens need broiler is a lower temperature/cold, then the temperature setting in this period is more controlled by the number of fans running on the other hand, and use cooling pad.

Setting the number of fans that are on in the period starter and finisher is different because in the period starter it is designed to be used for the heating and cooling of the room (space heater). While the fan settings in the period finisher more aimed at pursuing the target perceived temperature of the chicken (effective temperature), so the air velocity is needed to make the conditions in the cage to be lower temperature.

3. Air humidity

Air humidity conditions in tropical climates is a fairly high humidity level and the humidity level must be able to be controlled by the ventilation system closed house. This air humidity Parameter will indeed be a little more difficult to control with the system closed house than the air velocity and temperature in the cage.

However, with proper ventilation settings, the humidity conditions in the cage can be slightly controlled and not getting higher which will result in the environment in the cage getting hotter and the effective temperature felt by the chicken will be hotter.

Some ways that can be done to control humidity are :

- Air speed regulation

- Addition of heating when the period brooding period,

- Direction setting of incoming air velocity of inlet

- Inner curtain/curtain arrangement blocking period brooding period,

- Addition of paranet / nets outside the area inlet

- Settings cooling pad the right and not excessive

In addition to being able to control the microenvironment in the cage, closed house can also improve the conditions that support the increase in productivity broiler among others:

a. Feeder space and water space

Characteristics of cages closed house the use of a food processor (feeding systemand drink (watering system). The automatic system is applied to the cage closed house thus making human resource needs more efficient. With feeding system and watering system automatic it will be more appropriate in terms of availability and distribution of feed and drinking water.

Feeder space and water space must be considered because it will determine the amount feed intake and water intake chicken broiler. Examples of implementation feeder space for the type of feed automatic pan feeder is the determination of the number of chickens about 45-55 heads per pan feeder, while water space for the type of drinking place nipple drinker is 10-12 heads per nipple.

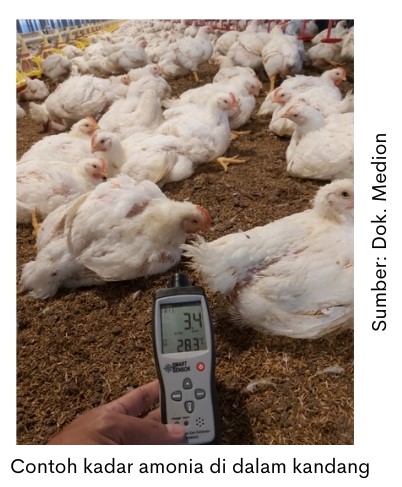

b. Ammonia content

Cage closed house can also control the ammonia content in the cage. Ammonia gas was found to have a high irritating power, especially on the mucous membranes in the eyes and in the respiratory tract of chickens.

When we enter the cage and the ammonia smell is smelled, it means that the ammonia level is above the threshold (>5 ppm). If the ammonia content is above that level, ammonia gas will cause harm to chickens, both in the form of damage to the eye and respiratory membranes.

Ammonia levels in the cage closed house it can be controlled in the following ways :

- Proper air circulation regulation

- Settings litter the good (do the reversal litter regularly every 3-4 days)

- Watch for leaks in drinking places

- Improve the nutritional quality of the ration (so that the feces do not get wet)

c. Uniformity

Chicken rearing broiler in the cage closed house will also increase the uniformity value. The value of weight uniformity on broiler it is said to be good if the value is >80%. This uniformity can be achieved because of the more uniform microenvironmental conditions in the cage so that the chicken will feel comfortable throughout the area in the cage.

Distribution of chickens in cages closed house the more spread evenly it will have an impact on the growing conditions of chickens broiler food and drink (feeder space and water space) also uniform.

| Uniformity Value | Remarks |

|---|---|

| 80% | Nice |

| 70% | Medium |

| 60% | Bad |

d. Harvest

Performance broiler on the cage closed house it will be optimal if at the end of the maintenance, that is, at the time of harvesting, it is done correctly. Important things to consider when harvesting are :

- Choose the right time and not hot (night)

- Reduced light intensity (reduced stress levels)

- Ventilation is maintained

- Feed in empty condition

- Feed is taken 8-12 hours earlier

- Strict harvest supervision

- Performed by skilled personnel

- Line feeder and line nipple shifted

- Minimize chicken activity during harvest

- Bulkhead for wide/long cages

- Biosecuritychicken coop, car and basket (clean and sprayed disinfectant)

In catching chickens, several things must also be considered, among others :

- Avoid broken wings and legs during harvest (mechanical factors)

- Catch and hold on both legs

- Restrictions on the number of catches (e.g. 3 tails per hand).

For a wide and spacious cage, during the harvesting process, a bulkhead can be installed before being caught.

e. Density

Other advantages of cages closed house it is more efficient because, the density of the cage can reach ③28 kg per m2, in contrast to the capacity open house which is only 8-10 heads per m2. Of Labor is also more efficient because for 1 operator cage closed house can handle 10,000 tail, while open house only able to handle 5,000-6,000 tail.

Density of chickens in cages closed house it is more correct to calculate based on the amount of body weight per square meter. This is related to the ability of the ventilation system to provide fresh air for chickens and the ability to lower the temperature of the cage.

Chicken Performance Broiler Management On The Cage Closed House

Successful maintenance of chickens broiler with the system closed house can be obtained by the application of appropriate management. Candidate must possess at least a bachelor's degree broiler and also the technical operation of the tool.

With the use of enclosure systems closed house, then human resources must really be trained on an ongoing basis in order to be competent. If the workforce is not competent in terms of production and technical operation of the tool then in when using equipment enclosure closed house there will be a lot of problems in the cage.

By using the enclosure system closed house then we can optimize the growth and increase the number of chickens in one cage (density). Cage size of 12 X 120 meters, using a cage system closed house then we can maximize the number of chickens broiler up to 20,000-22,000 heads. Then in one year we can harvest up to 7 times with a total harvest weight of about 42,000-46,000 kg/harvest cycle.

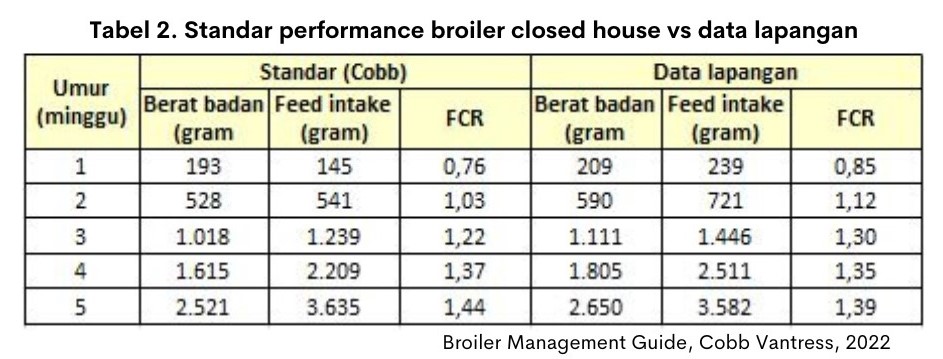

An example of a chicken's performance broiler with enclosure system closed house is as in Table 2. Cages used in the field data is the cage closed house with a standard size of 120 x 12 x 2 meters with a capacity of 22,000 tail. Chicken broiler in the cage is maintained until the age of harvest 31 days with an average harvest weight of 2.6 kg and get an IP value of 496.

Index performance (IP) is a formula commonly used to determine the performance of chicken broiler. The greater the IP value obtained, the better the performance of chickens and the more efficient the use of feed. IP value indicates a successful chicken production process that is influenced by mortality, FCR, body weight, and age of harvest. To calculate the IP value is as follows :

IP = (100 – plesi) x Bobot panen (kg) x 100

FCR x harvest Age (days)

IP = Indeks performance

FCR = Nilai feed conversion ratio

| Range | Value |

|---|---|

| <300 | Bad |

| 301-325 | Less |

| 326-350 | Enough |

| 351-400 | Good |

| 400-450 | Very Good |

| > 450 | Special |

To make productivity broiler be optimal and special can indeed be done with the manufacture of cages closed house. Cage making closed house itself requires a lot of cost, especially at the beginning of its construction, but the cost of production will be much cheaper because the cage closed house more durable and long lasting.

With the implementation of proper management in the maintenance of chickens broiler on the cage closed house then optimal performance will be obtained. These performances include broiler will grow faster and more efficiently in converting feed into meat (FCR).

Cage closed house it is also the best choice to minimize stress levels in chickens due to weather changes and can reduce mortality, so that chicken productivity increases and profits obtained by farmers also increase.

Similarly, information about the optimization of production with cages broiler closed house. May be useful.