Some basic needs that can be decisive in the success of performance or productivity in raising chickens include air, water and feed (steam). Water is second only to air. Water has a vital function for the chicken's body because it is the largest constituent component, which is 60-85% of all parts of its body.

Proper intake of drinking water in quantity and quality is very necessary for chickens to support the performance or productivity of chickens. For example, water in the body can play a role in regulating chicken body temperature, maintaining body fluid balance, food digestion media so that nutrients are better absorbed and support all physiological processes of the chicken body. In addition, water is also needed for operational activities in the farm such as environmental cleanliness of the farm, media for vaccination and medication, then sanitation and disinfection of cages, feed and drinking places, and other equipment that supports the rate of the farm.

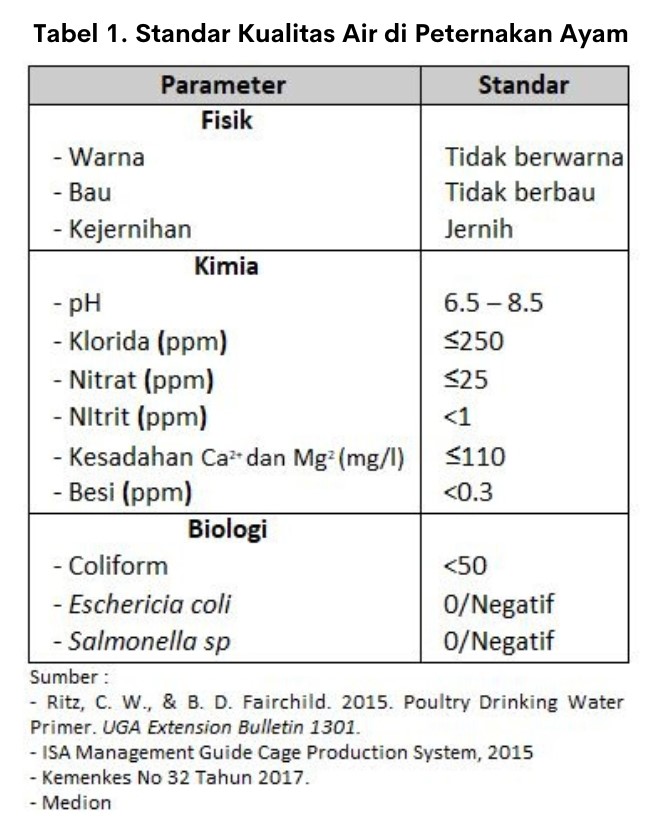

Once we know the importance of water, it becomes an obligation to pay attention to the quality of water used on farms, especially water that will be given or consumed by chickens. To determine the water quality standards, can be measured from several parameters, namely:

- Physical qualities

Physical qualities include color, odor, and water clarity

2. Chemical quality

Chemical qualities include pH, chloride content, nitrate, nitrite, iron and water hardness

3. Biological quality

Biological/bacterial quality in water can be measured qualitatively and quantitatively.

Qualitative observation by looking at the presence or absence of bacterial contamination. While the quantitative measurement by calculating the total amount of bacterial contamination such as coliform, Eschericia coli and Salmonella sp. of 100 mL of water sample.

Water Quality Standards

Maintaining water quality on farms is one part of biosecurity. Water quality problems will indirectly affect the decline in performance or productivity and even the health of livestock. Because water can be a medium of transmission of diseases such as Colibacillosis, Salmonellosis and other infectious diseases. Therefore, the importance of ensuring the quality of water on the farm, especially drinking water that will be consumed by livestock or water used for operational processes on the farm in accordance with established standards.

Water Quality Problems

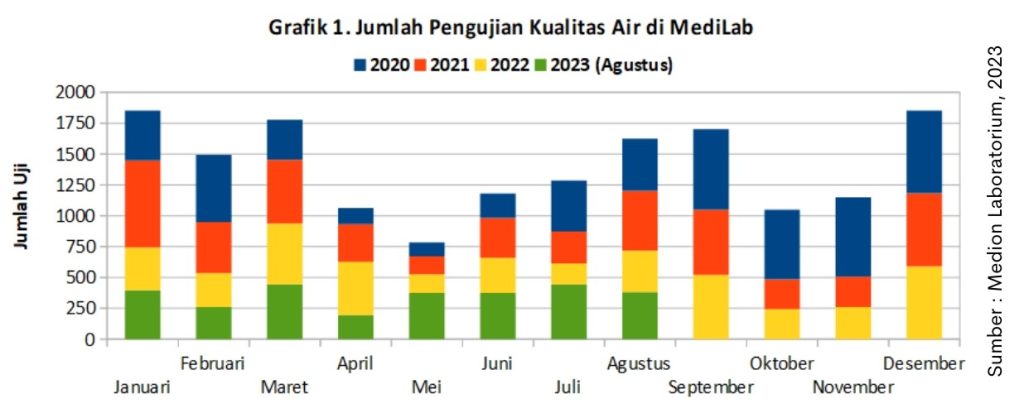

Water quality that is not in accordance with the standards, can certainly cause a decrease in the performance of chicken keeping. Because of the various impacts caused by problematic water quality ultimately have an impact on economic losses on livestock. The following data on water quality testing MediLab (Medion laboratories) during the years 2020 to 2023 (August).

Based on data on Graphic 1, the highest number of water quality tests from chicken farms occurred in January, February, March, August, September and December for the last 4 years to date. The total number of water quality tests reached 16,833 samples. It can be concluded that the number of water quality problems on chicken farms most often occurs when the turn of the season, especially the rainy season and the turn of the year (end to beginning of the year).

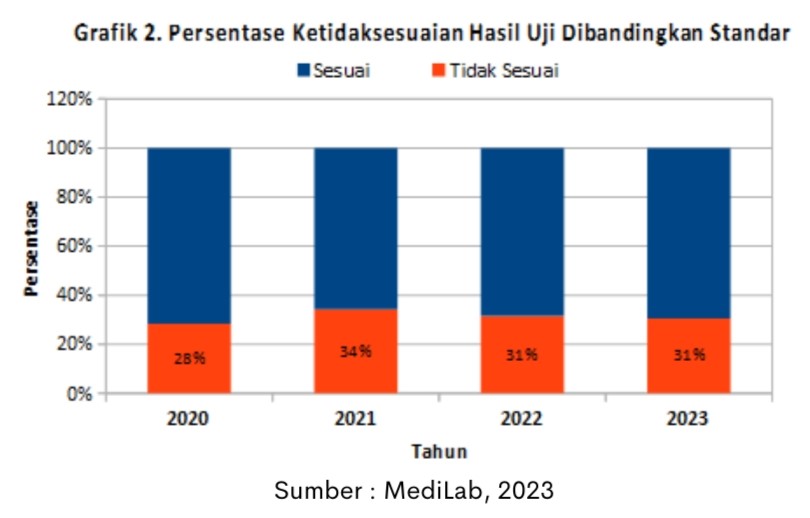

Based on the percentage of incompatibility of the test results on Graphic 2, an average of 31% of the samples did not meet the water quality standards for chicken farms with total testing parameters include physical, chemical and biological water quality.

a. Physical qualities

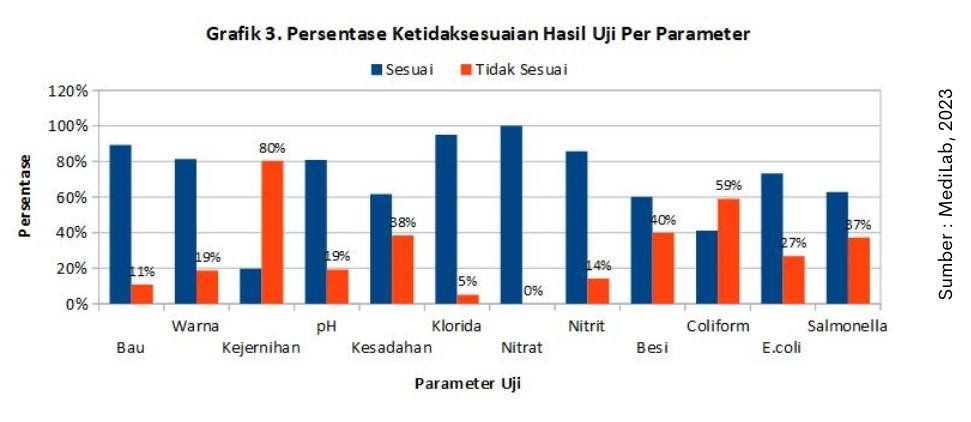

Based on data on Graphics 3, the percentage discrepancy of test results in comparison with the standard is still quite frequent. The percentage of mismatch between clarity, color and odor is respectively with values of 80%, 19% and 11%. Chicken drinking water should be clear, odorless, and colorless. The physical quality of water that is problematic is usually related to chemical levels or the number of bacteria that exceeds standard limits. So that the condition can cause changes in smell, color and water becomes cloudy. This can ultimately have an impact on reducing chicken drinking water consumption.

b. Chemical quality

The percentage of water chemical quality mismatch includes pH, hardness level, chloride, nitrate, nitrite and iron levels in a row with the value 19%, 88%, 5%, 0%, 14%, and 40%. Problematic water chemical quality can affect the chemical processes that occur in the chicken's body when consumed. It can also trigger chemical reactions when used as a solvent media for active vaccines, drugs, and vitamins via drinking water and disinfectants. This chemical reaction will eventually cause a decrease in the performance and effectiveness of the product, for example, the pH of the water is not up to standard.

The pH of the water in the farm should be between 6.5-8.5 or neutral. If it is higher (alkaline) or lower (acidic) than the standard limit, it is necessary to pay attention to the treatment of the water so as not to interfere with the physiological processes of the body and the rate of chicken farming.

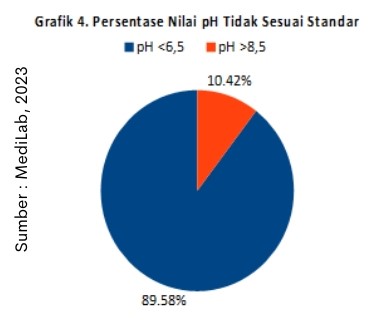

The amount of water in the water tank is less than the amount of water in the water tank (Graphics 4), sebanyak 89,58% sampel memiliki pH asam dan 10,42% pH basa. Menurut Hess dan Macklin (2019), unggas dapat mengonsumsi air minum dengan pH asam lebih baik daripada kondisi basa. Walaupun demikian, air dengan pH terlalu asam (<6,5) dapat mempengaruhi performa ayam, merusak peralatan peternakan, dan berpengaruh terhadap pelarutan obat dan vaksin. Sedangkan air yang terlalu basa (>8,5) mengindikasikan tingginya kadar kalsium dan magnesium dalam air. Kondisi pH yang terlalu basa bisa mengganggu pencernaan, menyebabkan diare, menurunkan feed intake, dan dapat menimbulkan kerak pada saluran air.

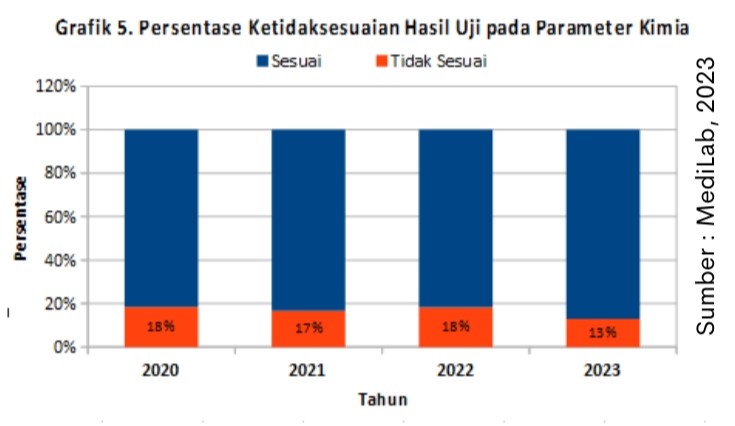

The percentage of non-conformance of chemical water quality test results compared to standards during 2020 to 2023 (August) averaged around 17% of the total testing of 5853 samples (Graphics 5). This shows that hundreds of samples tested are still potentially problematic or not up to standard. Including the problem of water hardness that can affect the operational process on the farm. Such as affecting medication (especially can reduce the effectiveness of the performance of fluoroquinolone and Tetracycline drugs), damaging active vaccines via drinking water, and when used as a disinfectant solvent.

Other parameters such as chloride levels also need to be known. Chloride in water is in the form of halogen chlorine (Cl) and will bind to Salt cations (for example: Na2+, Ca2+, Mg2+) to form salt compounds such as NaCl2, CaCl2, MgCl2. In high amounts (exceeding the standard), chloride will cause a salty taste in water so that chickens tend to increase drinking water consumption and reduce ration consumption. As a result, chickens will often get diarrhea. Another effect, high chloride will accelerate the occurrence of corrosion in drinking water installation systems or in cages.

In addition, the levels of nitrates and nitrites in the water also need to be known so that test results that are not in accordance with the standard can be evaluated immediately. Nitrite is a chemical compound derived from nitrate. Nitrate compounds themselves are produced in the final process of decomposition of organic matter such as feces. Excess nitrate content in water can decrease the potency of vaccines and drugs. Nitrates are not toxic to chickens. However, consumption in excessive amounts can only lead to poisoning. With the help of nitrogen-fixing bacteria, one of which is Rhizobium bacteria, nitrate can be converted into nitrite, which is 10 times more toxic than nitrate. Nitrite will bind to hemoglobin and lower oxygen levels in the blood, as a result of which chickens can experience death. In addition, excessive nitrite content can trigger the emergence of biofilms (Hubbard, 2020).

A wide variety of metals / minerals are commonly found in drinking water. Typically, such compounds are found in relatively low concentrations and do not pose a danger. Other metals to watch out for are iron. Concentrations that exceed standards can affect the smell, taste and color of water, cause diarrhea and cause crusts that can clog pipelines. It can also damage vaccine viruses, especially when vaccinated through drinking water, reduce the effectiveness of drugs, form complex compounds with tetracyclines, sulfonamide inactivation and accelerate the formation of biofilms along water installations. This is due to an increase in the population of pathogenic bacteria in the water. Biofilm in the water channel can inhibit the flow rate of water in the nipple channel so as to interfere with the dose of vaccines, drugs and vitamins consumed by chickens.

c. Biological quality

The percentage of incompatibility of water biological quality test results compared to standards including coliform 59%, E.coli 27% and Salmonella 37%. The presence of coliform bacteria is generally related to fecal contamination of drinking water due to runoff into surface water or groundwater. Ideally, bacterial contaminants should not be present in drinking water. Based on the data (Graphics 3), indicating that the risk of bacterial contamination of water in farms is still quite high. Water can be a medium of transmission of diseases such as Colibacillosis. So it needs to be treated in water to kill or inhibit the growth of pathogenic bacteria in the water so as not to cause disease.

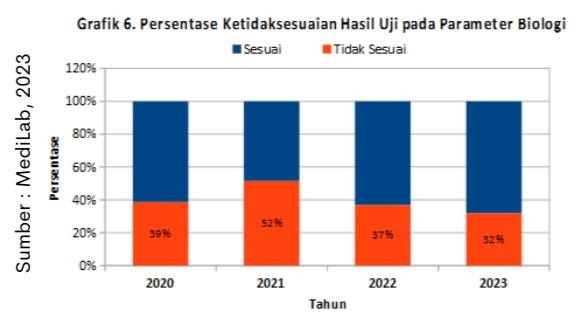

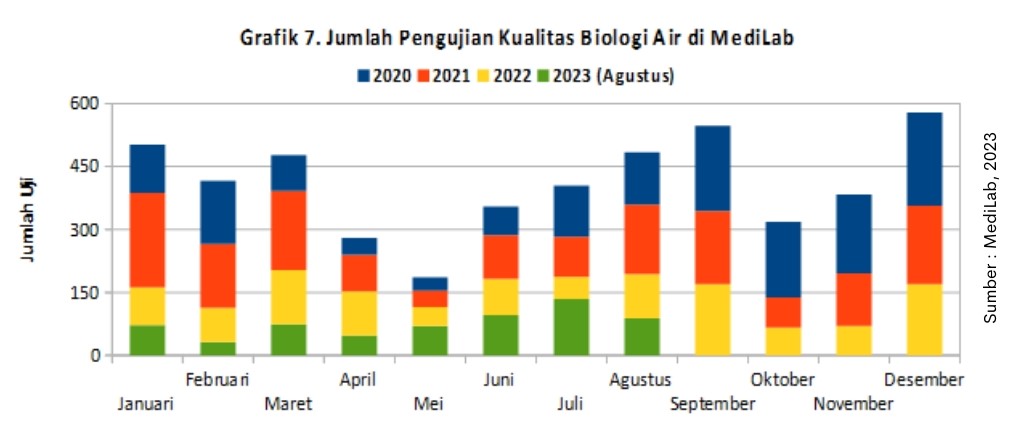

During 2020 to 2023 (August), the number of water biological quality tests was 4950 pieces with an average of 40% non-standard results (Graphics 6). High bacterial contamination of water is usually correlated with high cases of disease in the field, one of which is Colibacillosis. This is in accordance with the data on cases of disease in the field in broiler chickens and layers by the Medion team, showing that Colibacillosis is included in the top 5 disease ranking. Water sources that are too shallow, close to the source of piles of feces, near rice fields, rivers/swamps, or septic tanks, have a great risk of being contaminated with E.Col. Based on data on Graphics 7, indicating the number of biological quality testing of water (coliform, E.coli and Salmonella) from chicken farms were highest in January, March, August, September, and December during the years 2020 to 2023. It can be concluded that the number of biological water quality problems, such as high contamination of e bacteria.coli often occurs at the time of the change of season and towards the end to the beginning of the year.

Physical, chemical, and biological water quality that is not in accordance with the standards can affect the performance, productivity and rate of chicken farming which can ultimately cause economic losses. When water quality problems occur in one of the parameters, it may be quite easy to overcome them. But if left untreated, it can lead to more complex problems. For example, the mismatch of chemical and biological parameters that can result in handling is also increasingly complex.

Importance Of Water Quality Testing

Clean, uncontaminated water should be available to livestock at all times. However, depending on the source, the water supplied to the farm may contain excessive amounts of various minerals or be contaminated by bacteria.

One of the prevention efforts in dealing with water quality problems is through laboratory tests to ensure that water quality remains stable and livestock equipment, especially water installations, continue to function properly. Water quality tests can be carried out regularly, for example routinely every 1-2 months, when starting a new maintenance period, when changing water sources or when switching seasons and during the rainy season. Like at the end of this year or next December 2023 which is the rainy season.

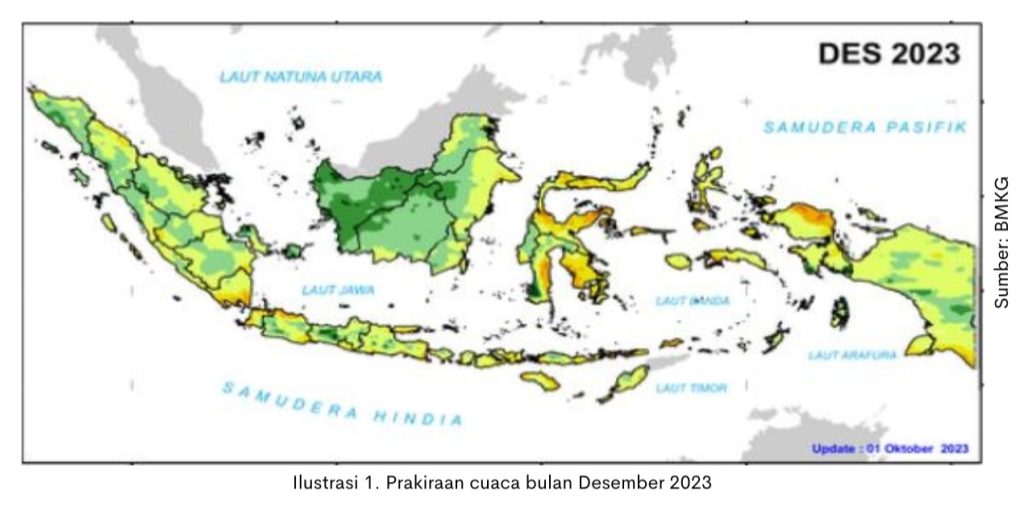

According to the Meteorology, Climatology and Geophysics agency (BMKG) on Illustration 1, the weather forecast at the end of 2023 to the beginning of 2024 is the rainy season with increasingly high rainfall. Of course, this becomes a shared awareness of the challenges in facing the rainy season. One example is the declining water quality due to high bacterial contamination. Therefore, it is necessary to test the water quality in MediLab to find out what are the problems of water quality on our farms.

MediLab is here to help problems in chicken farms, one of which serves water quality tests. Supported by advanced technology and reliable laboratory staff, MediLab provides test results and data interpretation that is fast, accurate, and complete, making it easier for farmers to make the right decisions. Through periodic testing, the next handling steps can be determined immediately.

Addressing Water Quality Issues

Water quality that is not up to standard can certainly cause problems on a farm. Not only affect the performance of livestock, but also a series of operational processes in the farm. The use of Water Treatment Plants can help process raw water into water that is suitable for consumption for livestock. Water Treatment plants are also able to maintain the quality of livestock drinking water according to standards, thus minimizing the risk of contamination in drinking water consumption that affects the health and performance of livestock. In addition, several ways that can be done when water quality problems such as:

a. Physical qualities

Handling of odor, color and clarity problems, can be done by filtration or filtration methods. It could also be another method of mixing alum into torn at a dose of 2.5 grams per 20 liters of drinking water. This alum serves as a purifier that can bind particles or minerals contained in water.

b. Chemical quality

Handling of water pH that does not match the standard, can be done by mixing Netrabil at a dose of 5 grams per liter of drinking water. In addition to the filtration method or mixing baking soda when the pH is acidic and citric acid when the pH is alkaline.

Handling of excess mineral/metal content can also be done by filtration method. The trick is to drain the water from the source to the filtration or filter tool in the form of silica sand/zeolite, activated carbon and manganese before flowing into torn. In addition, it can also mix Medimilk/Netrabil in the water.

c. Biological quality

Handling of microbial contamination (coliform, E.coli, Salmonella sp., etc.) can be done with drinking water sanitation using Desinsep at a dose of 30 ml per 1000 liters of water. Before use to dissolve drugs/vitamins/ herbs, drinking water containing Desinsep it should be settled in advance for 6-8 hours. In addition, it is also important to carry out flushing in drinking water installations to prevent the development of biofilms.

Water is an integral part of many biological processes in the body of livestock. Its quality is very important because it represents between 50-70% of the live weight of an adult chicken and the amount of water consumption is usually 2-2.5 times greater than the consumption of feed. In addition to being the main component of the body, water is also the main solvent involved in many metabolic processes. Even if it is considered a medium of disease transmission. Therefore, good water quality control begins with knowing the physical, chemical and biological properties of the water used through periodic water quality tests. Because quality water will support the success of the performance and rate of the farm.