Feed plays an important role in the cultivation of poultry because it occupies the largest position of the total production cost of about 70-85%. Feed also provides the nutrients needed for poultry to survive (maintenance) and production.

Good feeding management is needed so that feeding produces optimal livestock productivity while providing high profits. In addition, the homogeneity of the feed also has a no less important role.

Homogeneity Of Feed

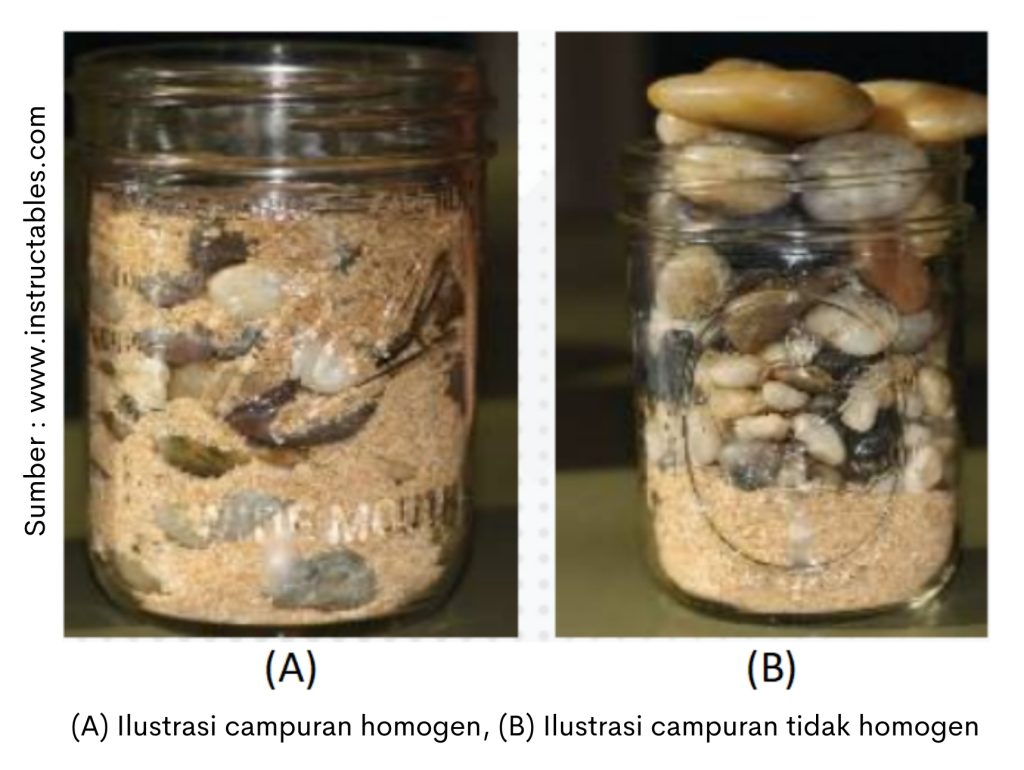

Homogeneity is a parameter to see the effectiveness of evenly or not mixing feed ingredients. Homogeneity test is one of the important tests in the formulation of feed, the aim is to determine whether the ingredients in the formulation are mixed evenly or not (Afianti and Mimiek, 2015).

Feed homogeneity greatly affects the productivity of chickens, such as the peak of egg production and uniformity of harvest weight. Therefore, feed homogeneity tests need to be carried out to ensure that each chicken receives the same nutrients as needed.

There are several critical points that need to be considered in order to produce a homogeneous feed mixture, namely:

1. Raw material particle size

Different particle sizes reduce the likelihood of mixing raw materials evenly and cause the feed mixture to separate again after previously mixing. Mixer has a threshold where the material with a large size can not be mixed well in the feed. The solution is to reduce the size of feed raw materials so that the particles can be scattered randomly and evenly.

2. Sequence of entering raw materials

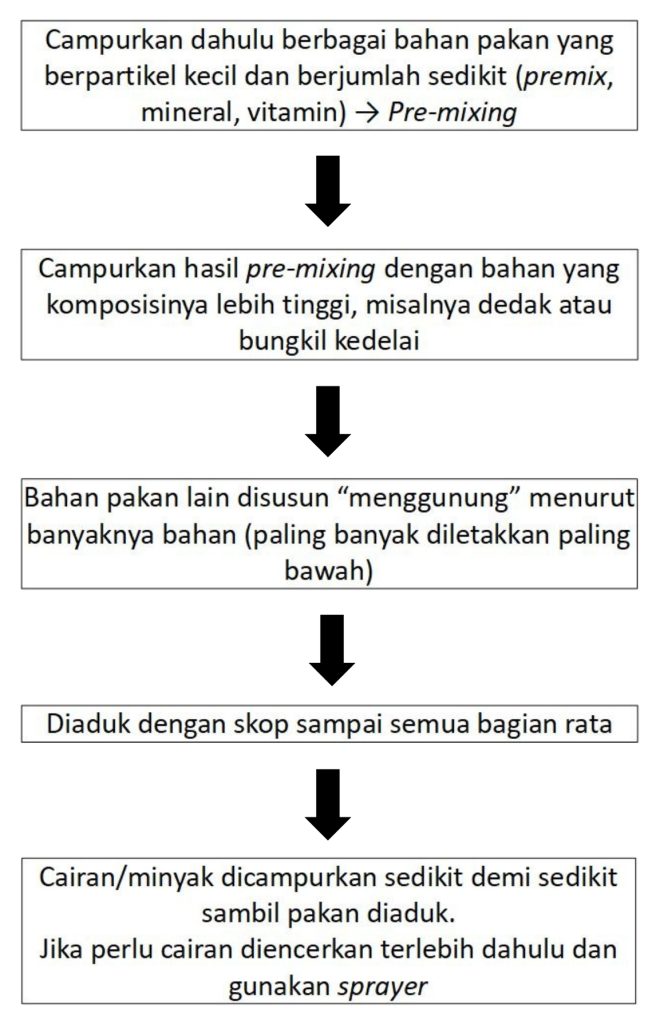

The order of inserting materials determines the dispersion of raw materials during mixing. For example, a small amount of raw materials, such as raw materials with very small particles and a small amount of premixes, are mixed separately (pre-mixing) so equally (Princess et al., 2017).

After that, the feed raw materials with the largest amount are introduced first into the mixer, followed by the rest of the ingredients sequentially (from the largest to the smallest amount). Lastly, new raw materials pre-mixing previously mixed.

How mixing according to Kartadisastra (2008) is :

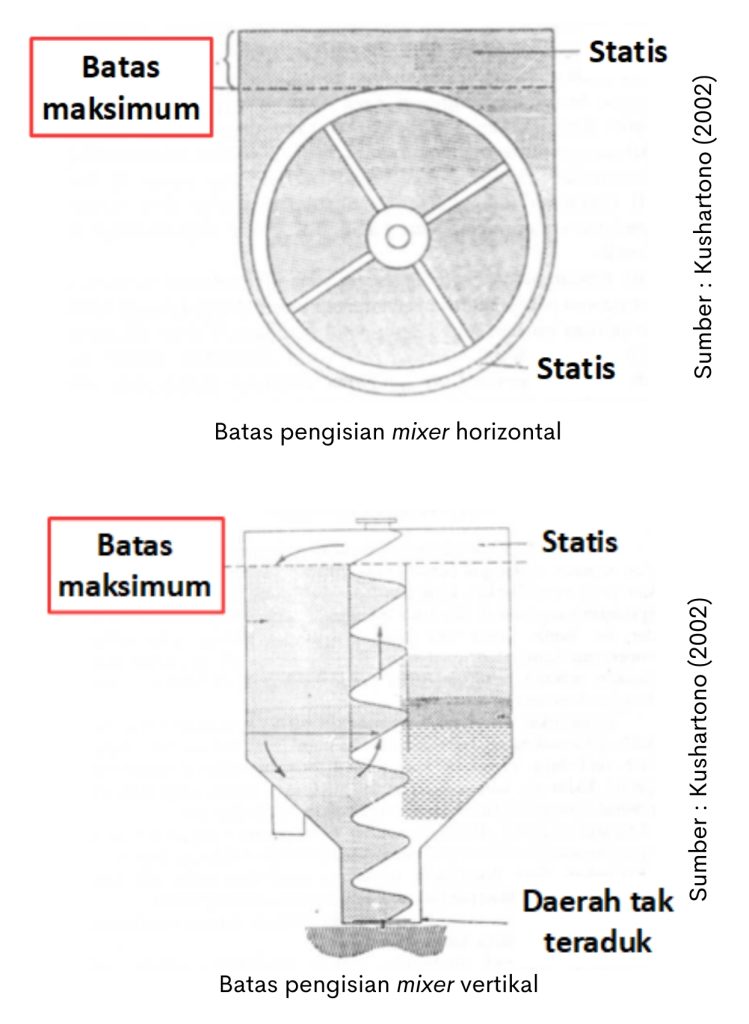

3. Mixer filling capacity

Capacity of filling raw materials into mixer affects the result of mixing. Overfilling can hinder the mixing process at the top mixer (Suparjo, 2010). Mixing will run efficiently if mixer filled to 60-90% of its capacity.

4. Duration of mixing

Adjust the duration of feed mixing. The duration is increased as the level of liquid material in the mixture increases, as the mixture becomes thicker and slows the flow of feed inside mixer. This risks causing layers on the sides and screw mixer, so that the mixing efficiency decreases and the risk of contaminating batch next.

Conversely, the duration of mixing is too long to allow segresi (separation of particles). Mixer horizontal (elongated shape) usually takes time mixing shorter (range 3-4 minutes) than mixer vertical. While mixer vertical type requires time process mixing longer, which is 10-15 minutes. Workers must have a disciplined attitude when mixing feed. For example, the time required for mixing is 15 minutes, then workers must follow this time.

Homogeneity Checking

Feed homogeneous mixing results will be representative, meaning it can describe the quality of the results mixing overall. To find out what our food mixing already homogeneous or not, can be tested for salt content (NaCl) as an indicator. According Suparjo (2010), good mixing will produce value coefficient of variation (CV) salt content below 10%.

Before testing the salt content,first do the sampling. Representative sampling on mixer vertical is very difficult to do directly, so it is recommended that samples be taken from the feed dispensing site at several time intervals during mixer stop.

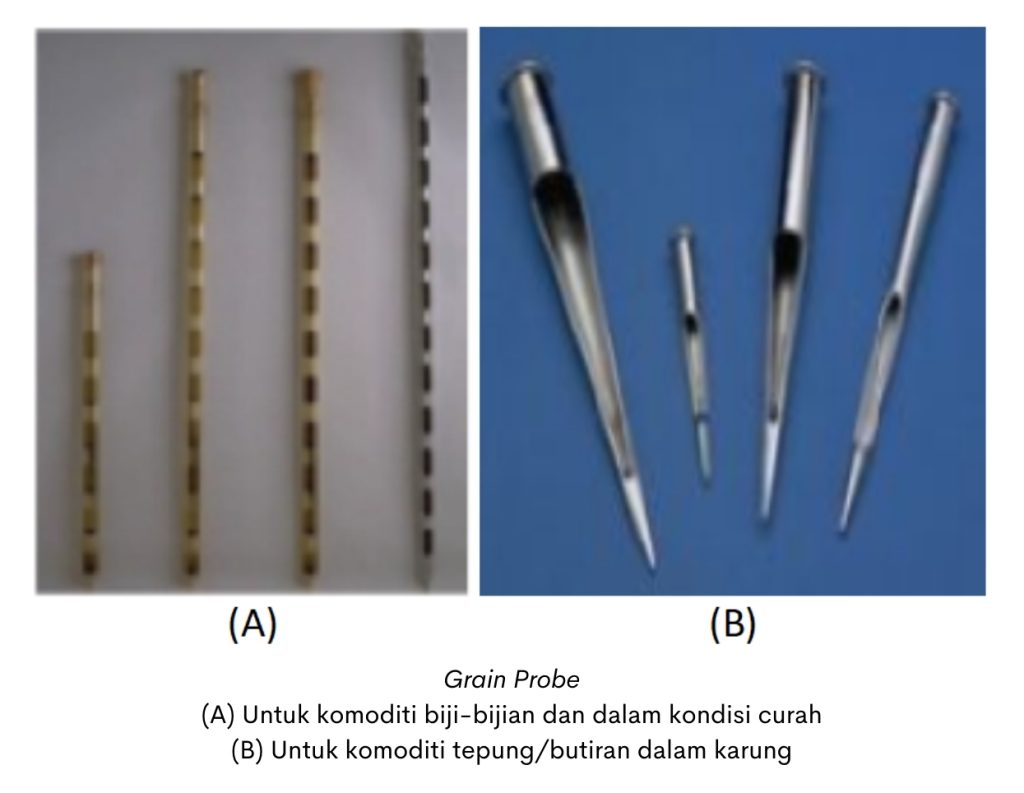

Meanwhile, samples can be taken from the top mixer horizontal. Probe used to take representative samples of grain or feed material. Select probe which corresponds to the particle shape of feed raw materials.

Tangendjaja (2018) gave an example of 10 feed samples taken randomly from 10 different locations at time intervals of 2, 4, 6, 8 and 10 minutes each in one stirring in mixer vertical. The sample is sent to the laboratory for analysis of the salt content.

For each period, the mean salt content and its standard deviation are used to calculate the coefficient of variation expressed in percent. For example, if the average salt content (NaCl) in the feed is 0.300% with a standard deviation of 0.027%, then the coefficient of variation or homogeneity is 0.027/0.300 multiplied by 100%, so the value is 9%.

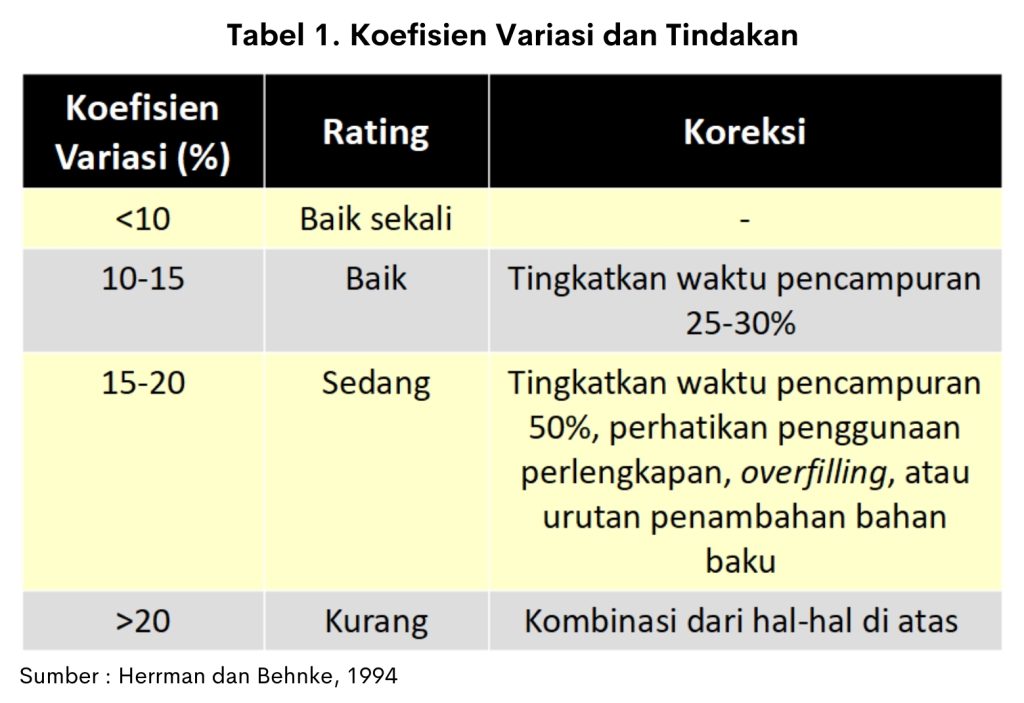

A high coefficient of variation indicates that the mixing process is not perfect. Incomplete mixing can be corrected by making adjustments mixer, replace the components used or change the procedure of entering raw materials (Suparjo, 2010). Chart 1. shows the coefficient of variation (CV) and correction measures in the feed mixing process.

Precision Feeding

Precision feeding this means providing feed to each livestock according to individual needs. Not just on an average basis, but daily and continuously. Giving feed lower than individual needs can reduce livestock performance.

Chicken uniformity plays an important role in the concept precision feeding. Examples flock broiler with a uniform body weight, it will grow uniformly and reach the weight of the harvest at the same age. This will make it easier to cut and process in RPA with automatic machines. In addition, uniformity is a major determinant of the first time laying eggs on layer and breeder. Then what does uniformity have to do with precision feeding?

The more uniform the chicken, the more uniform its nutritional needs will be. In practical terms, it is easier to meet individual nutrient needs if they are uniform.

If precision feeding done well, it can improve uniformity flok. Therefore, precision feeding and uniformity is interconnected as a cause-and-effect.

The main challenge in precision feeding is the supplementation of essential nutrients in small amounts, such as minerals, vitamins and amino acids. Because the level of administration is small, the homogeneity in the feed is a challenge.

Therefore, to face the challenges in the application precision feeding the principle of homogeneity of feed mixing is key.

Thus, this edition of the article, discusses the importance of homogeneity as the key to proper feeding. Hopefully useful and add to our insight. Success always.