Preparation ahead of production in the maintenance of chickens layer we must prepare appropriately so that the resulting egg production will be optimal. Some things we must consider before entering the production period include :

1. The right chicken moving process

The process of moving chickens begins with the preparation of production cages. The preparation of the cage for self-production starts from washing the cage and disinfecting the cage. Equipment for feeding and drinking should also be ready for use. Where to drink should already be done flushing to maintain the quality of drinking water, because the better the quality of the water, it will minimize the decrease in feed consumption after the removal of chickens. The production Cage must be in dry condition before the entry of chickens pullet, because the cage is still wet will cause the cage to be damp and cooler temperatures. For areas that are very cold, then the temperature of the cage can be raised first to be warmer before the chicken pullet get in.

The process of moving chickens pullet it should be done carefully because chickens experience stress. Stress can be caused by two things: :

Process handling and improper transportation

Process handling inappropriate will make chicken stress such as the wrong way to catch, the capacity of the chicken basket is not suitable, the condition of the transport vehicle is not feasible, and the placement of rough chicken.

Changes in the cage environment

Changes in the environment of the cage will also make the chicken stress. For example, when the chicken pullethis kept in a cage with a system closed house, while the production cage open house. So the chickens need to adapt to the new environmental conditions of the cage.

Poultry pullet those that have been moved will inevitably experience changes in the environment, temperature, humidity, and equipment system of the cage. Moving chickens pullet it should be done at the age of 12-14 weeks or 4 weeks before the production period begins. The goal is that chickens get enough time to recover from stress and ovarian development is not disturbed. Moving chickens too late can pose a risk of damage to the ovaries. If the chickens are moved too close to the initial period of laying eggs, then the risk of developing egg peritonitis increases. Movement from chickens whose ovaries have already developed and matured can cause rupture of the yolk follicle, which is then stored in the body cavity.

The ideal time to move chickens is the night until the morning or when the environmental conditions inside and outside the cage are not hot. Vehicles and chicken baskets must be in a clean and disinfected condition. If possible the chicken is moved within one day so as to minimize the impact of stress and not make the cage temperature conditions are too low due to the cage is not fully filled.

During the process of moving chickens should not be exposed directly to sunlight or rain because it will cause stress.

2. Body weight, uniformity, and feed intake which conforms to the standard

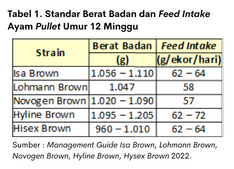

Berat badan/body weight dan tingkat keseragaman/uniformity pullet largely determines the success rate of the production period. The uniformity of good laying hens is >85%. Feed consumption/feed intake also must comply with the standards of each strains as in Table 1.

One of the important factors to consider is weight control on a weekly basis. Weighing is carried out regularly every week with a sample amount of about 0.5-5% of the population. Success indicators of maintenance management pullet laying hens are weight and uniformity corresponding to the standard. Regular and scheduled weighing can help evaluate performance pullet, so that if the target is not reached can quickly find a solution.

Here are the things that must be considered when making a decision sampling :

- The number of samples is sufficient and evenly distributed in each part of the cage.

- The weighing method should also perindividu chicken.

- The scales used are calibrated.

- The need for total selection with individual weighing before being moved to the production cage.

- Weighing time is carried out at a fixed time.

- Weigh Data is made in the form of graphs making it easier to analyze the results weigh.

From the results of the weigh we can also do grading. Grading what can be done is to separate the chicken based on its weight on battery different. Different feeding can also be done after grading. After the process grading, then the feeding is also different.

Each has its own way of dealing with pullet with a small weight or less than the standard can catch up and uniformity target can be achieved.

Pullet with a body weight less than the standard can be fed more than pullet with standard weight. While pullet with a body weight that exceeds the standard, the addition of feed the next week can be held.

A good midnight feeding can be done to improve feed intake that is, by increasing the duration of the lamp flame at night so that the chickens have an additional opportunity to consume feed. Feeding Program in the period pullet also must be adjusted to the maintenance standards of each strains laying hens.

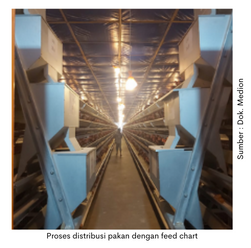

Feeding can be done 2 times a day, that is, the first time in the morning in a smaller amount (30-40%), then the second in the afternoon in a larger amount (60-70%). The distance between the two meals, there is a period of empty feed about 1-1.5 hours.

This method will make the chicken's intestines develop well, as it stimulates the chicken to eat faster and more. If the chicken is fed once a day, the chicken's intestines will not develop properly, because the chicken feels that the feed is available at all times, so there is no stimulus to eat quickly.

Actions that can be done if the chicken's body weight is less than the standard is to delay the time of the beginning of laying eggs and avoid rapid light stimulation. If chickens are forced to lay eggs, there will be a rapid decline in production when they enter the peak egg-laying period. Another thing that will happen is that the size of the eggs will be smaller and not uniform, as well as short production persistence. Another risk is increasing cases of prolapse and can encourage cannibalism.

3. Avoid production inhibiting factors and production persistence

Good production persistence is the ability or endurance of chickens to produce over a long period of time. The peak and persistence of the production target is in accordance with the standards or can even exceed the standards of each strains laying hens.

Peak production standards for strain Isa Brown is 96.5% with production persistence >90% about 37 weeks (ISA Brown Cage Housing Product Guide, 2022). Peak and persistence of good production must be supported by management starter, grower, and layer right so that the chicken will be obtained layer quality.

Factors that inhibit the peak of production and persistence of production can come from infectious factors and non-infectious factors. These factors must be prevented and avoided so that they do not interfere with egg production. Infectious factors are production-inhibiting factors caused by disease. Diagnosis of a disease requires Anamnesis, examination of clinical symptoms, examination of anatomical changes through necropsy, and laboratory testing when needed. These diseases include the following :

Infectious Bronchitis (IB) virus of

Decrease in egg production can reach 70% with changes in eggshell asymmetrical, rough, thin, pale, watery egg white, and there blood spot on the yolk. Anatomical changes characterize the presence of inflammation in bifurcatio trakhealis-bronchus, swollen/flabby ovaries, oviduct cyst, and swollen kidneys.

Egg Drop Syndrome (EDS)

The decrease in egg production can reach 10-40% with the characteristic of soft eggs/without shells.

Newcastle Disease (ND)

The decrease in egg production can reach 9-60% with pale and small eggs or what is often known as pigeon egg. Symptoms that characterize the chicken torticollis with anatomical changes in the presence of inflammation papilla / nodulproventriculus, found payer patches in the intestines, and ovaries fertilize.

Avian Influenza (AI)

High Pathogenic Avian Influenza (HPAI) led to a decrease in production to 40%, while Low Pathogenic Avian Influenza (LPAI) led to a decrease in production to 50% or even more. High mortality cases can be found in single HPAI cases. In the case of a single LPAI more impact on the decline in production and effects immunosupressive which is necessary to watch out for, while for cases of death are rarely found. Symptoms that appear are bluish Combs and legs. Anatomical changes that characterize the dilatation of blood vessels of the brain, bleeding in the heart, muscles, and proventriculus, ovarian swelling/ bleeding, and swollen kidneys.

Factors that include non-infectious causes of egg drop are:

Quality pullet

Chicken quality pullet which will be maintained largely determine the success or performance from laying hens because pullet quality will result in optimal egg production. Chicken pullet a good one will turn out chicken layer which is also good so that it will get optimal production peaks and long production persistence. Quality pullet good characterized by body weight according to standards, uniformity of body weight, skeleton (sternum and shank), and sexual maturity meet standard >85%.

Combs have grown and are red, the distance os pubis 2-3 fingers, the distance between the sternum and the cloaca is about 3-4 fingers, the length of the shank/lower leg bone is about 10 cm. In addition to a well-built posture and a large cache. If these qualifications are not met, the chicken may be late to lay eggs, production does not reach the peak, or the persistence of high egg production is only short-lived.

Nutrition of feed and drinking water

The feed given can also affect the amount of egg production, because Feed is the main source for chickens in producing eggs. Egg production is greatly influenced by the nutrients contained in the feed such as protein, amino acids, energy, fat, crude fiber, and vitamins and minerals. Non-fulfillment of the needs of any of these nutrients can lead to disruption of egg production. These nutritional needs can not be met due to decreased feed consumption, for example due to hot weather. Drinking water consumption can also affect low production. Low consumption of drinking water affects the low consumption of feed to the impact of egg production fulfillment of these nutrients can be assisted by the provision of premix like Endomix.

Maintenance management

Management factors that affect the peak production and persistence of production include :

a. Cage manager / operator

Peak production and persistence of good production can be achieved if the cage manager really understands the management of laying hens and proper management of the cage. Starting from routine control for chicken conditions and cage conditions so that if there are deviations in production or performance can be immediately corrected.

b. Enclosure environment

Kondisi lingkungan di dalam kandang yang tepat akan membuat ayam nyaman. Jika kondisi lingkungan kandang tidak sesuai dengan tingkat kenyamanaan ayam maka yang terjadi adalah produksi telur akan turun atau tidak sesuai standar. Kondisi lingkungan tersebut misalnya kadar amonia di dalam kandang yang dihasilkan dari reaksi penguraian feses dengan kelembapan sehingga terbentuk amonia. Amonia akan berdampak terhadap kondisi kesehatan saluran pernapasan ayam yaitu dapat merusak permukaan saluran pernapasan. Kadar amonia yang ideal adalah <5 ppm. Untuk mengontrol dan mencegah pembentukan amonia di kandang bisa diberikan Ammotrol. Ammonia levels are greatly influenced by air circulation. Good air circulation will immediately remove ammonia in the cage and prevent the formation of ammonia quickly due to humid cage conditions.

c. Lighting system

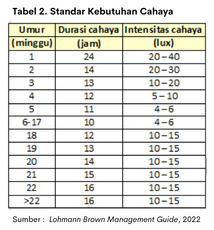

Lighting system or lighting system serves to provide light with the right intensity and duration for the development of chickens from the period starter until the layer as in Table 2.

Light optimizes growth pullet, sexual maturity, egg weight and egg production. Therefore, the duration and intensity of the light must be observed so that the lighting program is right. In the period starter lighting serves to make chickens active and spread evenly, helps chickens in consuming feed and drinking water, helps in the process of forming growth hormone. While in the final period grower up to layer lighting serves to stimulate reproductive hormones and the process of egg formation. Chicken layer which has entered the production period requires 16 hours of lighting, while the light intensity required during production is in the range of 15 Lux.

d. Equipment closed house

Tools closed house among other fan/exhaust fan and air conditioning system/cooling pad. Fan/exhaust fan cool the cage by giving a cool effect with the air velocity/windchill effect, while cooling pad cool the cage by lowering the temperature of the air that will enter the cage through the evaporation process. The equipment serves to create comfortable housing conditions in accordance with the needs of chickens. Target microclimate conditions inside the cage layer namely the temperature of 20-22°C with a humidity of 60-70%.

If there is damage to the machine it will interfere with the performance of the chicken layer. For example, the cage becomes hot and humid caused by a broken fan or improper arrangement. The organization of the ventilation system plays a role in creating comfortable conditions for the microenvironment inside the cage.

The ventilation system serves to circulate air, provide oxygen, remove moisture, remove harmful gases such as ammonia, CO, CO₂, and cool the temperature in the cage. If the ventilation system is impaired, it will have an impact on the effective temperature felt by the chicken so that the chicken becomes hotter.

To make the microclimate conditions in the cage such as temperature, humidity, and air velocity more controllable and targeted, system equipment can be used Closed House Medion.

Factors that affect the peak and persistence of production in layer chickens that have been described above we should be able to control and prevent before fatal to egg production is to pay attention to the start of labor, quality pullet and chicken layer, the right health program, cage equipment that works perfectly, maintain comfortable environmental conditions for chickens and the implementation of proper feed management and biosecurity so that performance chicken layer will be optimal.

To support the performance of chickens layer at the time of laying eggs it can be given Eggstima, namely herbs that serve to help increase egg production, egg weight and thicken egg shells.

Perform maintenance management improvements since brooding period, until the period laying and follow the maintenance management steps according to each guide strains chicken layer. In addition, management improvements from chicken managers or operators such as understanding the correct maintenance patterns, skills in working and willingness to carry out operational procedures that suit the needs of each chicken genetic owned.

We must pay attention to all of these things so that production and production persistence can last long enough in accordance with the standards. With peak production and persistence of good production, the profits obtained by farmers will be optimal.