It is important to note that the use of a food processor in the production of a food processor is essential for the production of a food processor (maintenance) and produce. Good feed processing management is needed so that the feed provided is of good quality and can produce livestock with optimal productivity.

Matters that must be considered related to how to make good feed (CPPB) based on the decree of the Minister of Agriculture No. 240 of 2003 is the procurement of raw materials, preparation, storage, mixing, making pellet, packaging, labeling and storage.

In this article, we will focus on the process of mixing (mixing) feed. Through the mixing process will produce a balanced and homogeneous feed so that each poultry obtain adequate nutritional intake.

Feed mixing can be done with two techniques, namely manually and using mixer (automatic). Both techniques can be used to self mixing, semi self mixing and self pre-mixing.

Breeders self mixing thoroughly mix each component of the feed ingredients themselves to be used as feed with additional premix. Meanwhile, semi self mixing breeders mix only factory concentrate with ground corn and Bran/Bran. As for the self pre-mixing farmers mix each component of feed raw materials including components of premixvitamins, minerals, amino acids).

In general, the mixing stage consists of stirring and randomization. Stirring is done to obtain uniformity, while randomization to obtain diversity. According to Putri et al. (2017), in the process of mixing (manual and mixer) there are three processes that occur, namely :

- Transfer of groups of particles from one location to another in a given volume of feed

- Diffusion, namely the spread of particles on a surface formed as a result of the stirring process

- Shearing, that is, the process of particle infiltration among other particles.

Manual Mixing

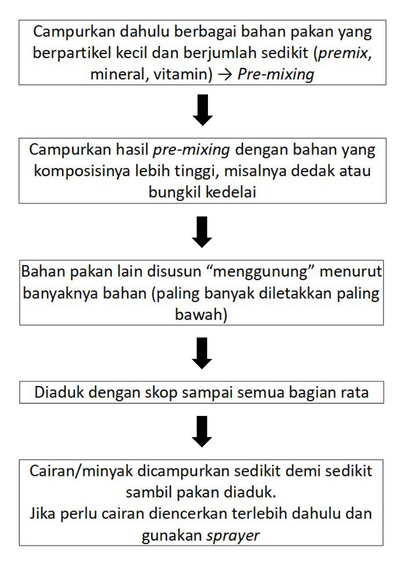

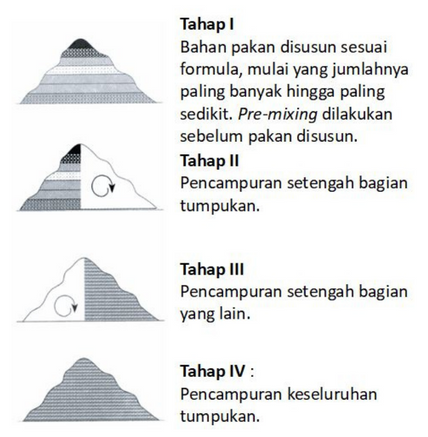

Manual mixing of feed is carried out with a shovel. Mixing should take place on a clean, level base, for example, on a bed of tarpaulin or plastic. Feed ingredients that have been weighed according to the composition are prepared and then mixed. How mixing according to Kartadisastra (2008) is:

The stirring process follows the following steps:

The mixing process is said to have taken place well or to have achieved a good degree of uniformity if the components of the feedstuff have been randomly distributed in other components. Manual mixing of feed is simple and does not require high costs for the purchase of a machine, but usually the quality of the resulting product is less uniform and requires a lot of Labor.

Automatic Mixing

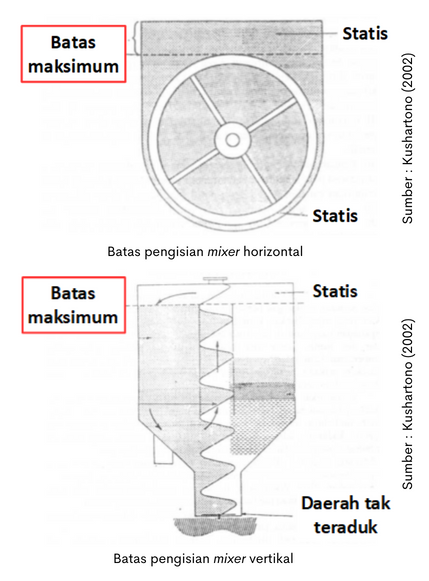

Feed mixing is automatically carried out inside the mixer. All mixers sold on the market are batch mixer, that is, all feed ingredients are introduced together at one time. The mixing sequence of feed ingredients is the same as the manual mixing method. It is important to note that the input of feed ingredients in the mixer should not be too full to avoid uneven mixing of the feed. This is because the feed ingredients above will be static and not mixed with other feed ingredients. The correct material limitation is that it should not exceed the height of the stirrer.

Mechanism of action mixer is to move the stirrer to mix the various ingredients in the tube evenly. Feed mixers can be categorized into mixer static and moving (mobile), with two types of movement, namely vertical and horizontal.

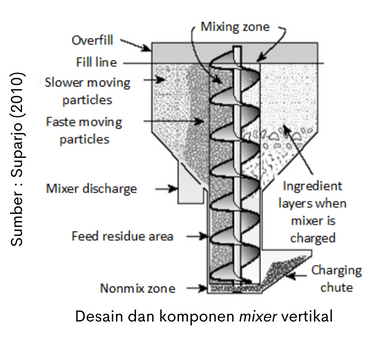

1. Mixer vertical

It consists of a large tube with one or more stirrers (screw) vertical in it. The stirrer brings the feed ingredients to the top mixer, then due to the force of gravity of the feed material particles will fall down to the next brought up back. A continuous process of about 10-15 minutes will create an even mixture of ingredients.

Mixer vertikal it is less efficient to mix solid and liquid materials at once or materials with different particle sizes and densities. Besides, mixer this type is also difficult to clean, allowing contamination between batch mixing and demanding precise mixing duration.

Stirring that exceeds the ideal time actually makes the mixture that is actually homogeneous become inhomogeneous (segmented/separated back). However, vertical mixers have the advantage that they have a larger capacity than horizontal mixers and do not take up much space.

On the market mixer vertical contained in the capacity of 500-2000 kg per batch. In addition to static, mixer vertical can also be applied mobile.

2. Mixer horizontal

It consists of one or two stirring devices installed horizontally. The rotating stirrer will unite the feed ingredients to the center mixer, then stir it sideways and up to return to the bottom mixer. If there are two stirrers, then one stirrer will direct the feed in the opposite direction to the other stirrer, so that the feed ingredients will move from the right-left side and up-down.

Critical Points Of The Feed Mixing Process

The key to success in mixing the feed lies in the homogeneity of the feed mixing results. Therefore, there are several critical points that need to be considered in order to produce a homogeneous mixture, namely:

Particle size

Different feed particle sizes reduce the likelihood of mixing raw materials evenly and cause the feed mixture to separate again after previously mixing. Mixer have a threshold where the material with a small size can not be mixed in the feed. The solution is to reduce the size of the feed material so that the particles can be scattered randomly and evenly.

Sequence of entering raw materials

The order of inserting materials determines the dispersion of raw materials during mixing. Feed ingredients that have very small particles and small amounts for example premix pre-treatment (pre-mixing) so equally (Princess et al., 2017).

Charging capacity mixer

Capacity of filling raw materials into mixer affect the result of mixing. Overfilling can hinder the mixing process at the top mixer (Suparjo, 2010). Mixing will run efficiently if the mixer is filled to 60-90% of its capacity.

Duration of mixing

Adjust the duration of feed mixing. The duration is increased as the level of liquid material in the mixture increases, as the mixture becomes thicker and slows the flow of feed inside mixer. This risks causing layers on the sides and screw mixer, so that the mixing efficiency decreases and the risk of contaminating the next batch. Conversely, the duration of mixing is too long to allow segresi (separation of particles).

Homogeneity Checking

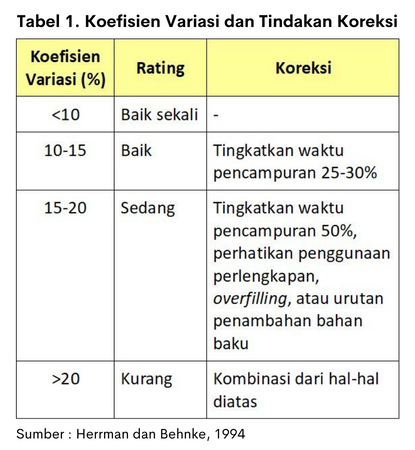

Feed homogeneous mixing results will be representative, meaning it can describe the quality of the results mixing overall. To find out what our food mixing already homogeneous or not, can be tested for salt content (NaCl) as an indicator. According Suparjo (2010), good mixing will produce value coefficient of variation (CV) salt content below 10%.

The average salt content of the test results and its deviation are used to calculate the coefficient of variation expressed in percent. For example, if the average salt content in the feed is 0.300% with a standard deviation of 0.027%, then the coefficient of variation or homogeneity is 0.027/0.300 multiplied by 100%, so the value is 9%.

A high coefficient of variation indicates that the mixing process is not perfect. Incomplete mixing can be corrected by making adjustments mixer, replace the components used or change the procedure of entering raw materials (Suparjo, 2010). Chart 1. shows the coefficient of variation (CV) and correction measures in the feed mixing process.

Proper feed mixing techniques with attention to critical points need to be done to ensure the homogeneity of the final product produced. Homogeneous and quality feeding will ensure optimal livestock production.

So at a glance info about feed mixing techniques. Hopefully useful and add to our insight. Success always.