Cages are one of the components that determine the success of livestock farming. The existence of technological innovation closed house can support the successful achievement of poultry farming. Enclosure system closed house it has been widely used in the broiler business (broilerhow do you get rid of ants in your garden? (layer)?

Chicken Challenge Layer Modern

Poultry layer modern eggs are produced from good genetic research so that they are formed more productive and more efficient in producing eggs. It has the ability to produce large amounts of protein (hen day height, red) and the intensity of a long time (persistence of good egg production, red), as well as obtaining a good level of ration efficiency. However, chicken layer modern turned out to have some side flaws.

One of them is chicken layer modern is also more sensitive to environmental changes. Breeding chickens also need an ideal living environment, especially influenced by ambient temperature and humidity. Especially in the production phase should have a temperature of 25-28°C and humidity of 60-70%.

Because some parts of Indonesia often occur to have temperatures higher than 25°C and often extreme weather changes, natural environmental conditions are not always good for chicken production layer.

Enclosure System Closed House

A comfortable Cage is one of the key supporters of optimal growth and productivity. In this cage, all the needs for growing must be available, including a good air ventilation system, optimal air temperature and humidity as well as sufficient and quality drinking water and rations.

Most of the heat in the cage is produced by chickens, especially during the production phase and the rest is heat from the roof, building walls, and lights. The use of closed enclosures or closed house being a solution for farmers to maximize the ability of chicken production.

Closed house it is a closed enclosure system that can help optimize environmental conditions including ventilation, temperature and humidity. On the cage closed house there is a stable air movement and the humidity level in the cage can be adjusted according to the needs of the chicken.

The temperature felt by the chicken's body is called the effective temperature. This effective temperature is influenced by 3 factors, namely room temperature (the temperature detected in the thermometer), humidity and airflow speed in the cage (which hits the chicken's body). Air humidity (relative humidity or RH) is the level of water vapor contained in the air.

Humid air (containing a lot of water vapor) will inhibit the rate of evaporation from the chicken's body, so that the temperature felt by the chicken will be higher than room temperature (thermometer temperature). Although the thermometer temperature is high, but if there is air flow, the temperature felt by the chicken's body will be lower. This is what is called chilling effect.

Wind chill effect is the effect of a decrease in temperature that is felt due to wind gusts on the surface of the body/skin of the chicken. Closed house a good one must be able to produce the wind speed needed to produce a suitable temperature for the chicken.

System closed house will ensure air exchange (air exchange) occur in the appropriate duration. For example, within 1 minute, the entire volume of air in the cage has been removed and replaced with new air from the outside.

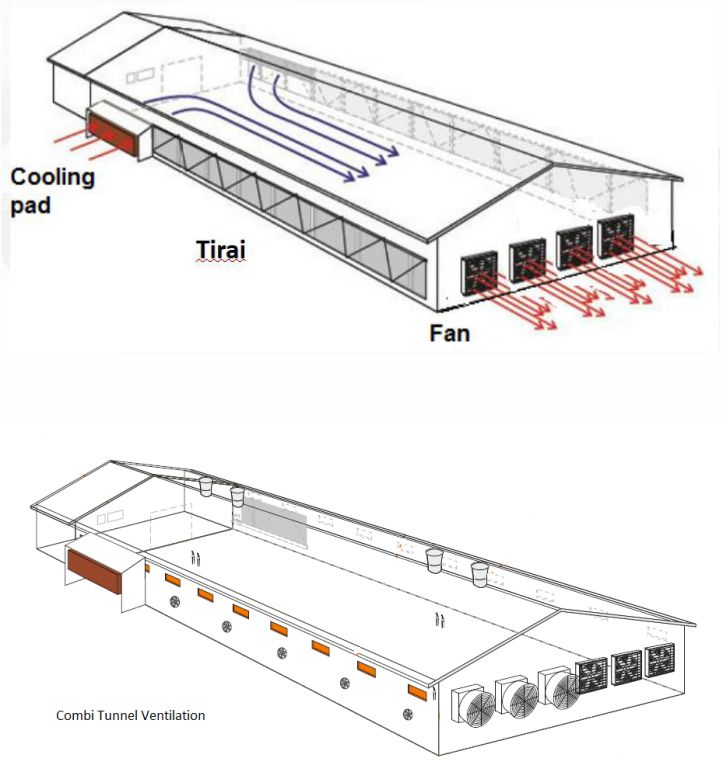

There are 2 forms of ventilation systems in cages closed house commonly used in poultry farming layer, namely tunnel and combined cross and tunnel. Ventilation system tunnel this means that air flows from the front to the back of the cage, like a tunnel.

This system provides wind chill effect maximum and commonly used for Phase layer where chickens have grown up and need a lower temperature.

While the combined ventilation system cross and tunnel combining ventilation systems tunnel with ventilation cross. On the ventilation system cross air flows from one side of the cage to the other. In this way, the system cross can quickly replace the air in the cage, without causing high wind speed.

When the warm temperature in the cage needs to be maintained and the chicken does not need cooling, the air will enter from the side of the cage at a low speed so that it only provides fresh air change but does not produce wind chill effect. When the chicken starts to need cooling, air will enter from the front of the cage and produce wind chill effect such as ventilation tunnel.

Combined ventilation systems are usually used in the magnification period (phase pullet) where there is a transition from chicken conditions that require warmth to conditions where the temperature is more ideal (not too hot and not too cold).

In addition to offering advantages in terms of air supply, closed house also equipped with automatic equipment to provide drinking water and feed, collect eggs, and remove feces on the battery cage. Thus, it can affect labor efficiency.

System Benefits Closed House to Layer Chicken

System Closed House and automatic equipment on the rearing of chickens layer able to help improve production performance and egg quality. In addition to related production performance, automatic feeding significantly saves feed costs, because the feed intake received by chickens can be more uniform, there is no wasted feed when distributing feed.

This has an effect on the fulfillment of the nutritional needs of chickens so that the weight of eggs and the percentage of egg production becomes more optimal. And also the provision of drinking that is not easily scattered.

Cage closed house considered more environmentally friendly to settlements or the environment around the cage. Infection from outside can automatically be minimized and of course the presence of automatic flies is reduced because the smell is more controlled. Biosecurity applications become easier to implement so that efforts to maintain chicken Health become much better.

Cage closed house it is easy to set up, and able to reduce operating costs because it is intended for long-term investment. Not based on how expensive the price of the cage, but also must consider the cage is able to provide a good environmental effect for chickens. Evidenced by the achievement of uniform body weight according to the standards that affect maximum productivity.

Components Closed House on the maintenance of chickens Layer

A. Ventilation system

The ventilation system has 4 main components, namely the fan, cooling pad (in the system) tunnel) or inlet (in the system) cross) and electronic devices called controller.

1. Fanfan)

Fan on closed house is a kind of fan exhaust and mounted on the back of the cage (system tunnel) because it serves to draw air from the front of the cage. Air will move from the front of the cage and out of the back of the cage through the fan exhaust installed.

While the ventilation system cross at the farm layer will use the fan/fan on both sides of the right and left of the cage and use wall inlet as a path for air to enter.

The fan that is installed can remove the hot air in the cage so that it can produce the level of humidity and temperature that is in accordance with what the chicken needs. Air pressure (pressure static) on the cage layer cages higher than the cage with a postal model.

Therefore, the calculation of the air capacity of the selected fan must be able to work on pressure static certain. This is so that the calculation of the number of fans used is right and the ventilation needs are met optimally.

Over time of use, the capacity of the fan will definitely decrease so that it affects the volume of air produced. Therefore, fan maintenance is important to do regularly.

2. Cooling Pad

Fan paired with cooling pad. The fan is where the air out of the cage, while cooling pad is where the air enters the cage. Cooling pad is an arrangement of corrugated paper that forms a certain pattern to direct the flow of air entering the cage. Cooling pad strung together with a water circulation system that is useful for wetting cooling pad.

Extents cooling pad calculated based on the number of fan which is installed so that the incoming air is balanced with the discharged Air. Cooling pad installed on the front and side of the cage, so it is shaped like the letter “U”.

Cooling pad using the principle of evaporation or evaporation of water to lower the temperature of the air from the outside that is inserted into the cage. Some of the heat energy from the outside air will be used to evaporate the water in cooling pad so that the air temperature will drop.

Over time use, cooling pad it can be overgrown with Moss and mold, as well as a buildup of minerals such as calcium. The amount of water that is used in the treatment of dry skin can be reduced to a small amount (treatment) on water. Cleaning mold and mildew by using appropriate chemicals will improve the function cooling pad. Cooling pad those that have been damaged (usually torn or weathered) need to be replaced.

3. Controller

Air regulation system in cages closed house can be run automatically with controller. Controller will regulate the work of the equipment by reading the sensors and following the inputted settings. When the temperature rises, the chicken needs cooling, controller will multiply the fan on or increase the rotation of the fan or drain the water on cooling pad until the air temperature will drop. Conversely, when the temperature is too cold, controller will reduce the number of rotating fans or fan rotation and prevent water from flowing in cooling pad.

B. Heating system

In the early days of preservation or time starter, chickens need a cage temperature in the range of 30-33°C. This need can be achieved using artificial heating.

Space heater (Super Saver Heater) will work to warm the chicken by spreading a stream of heat leading throughout the cage. Working principle space heater similar to a hair dryer or hand. Space heater generally, it has a capacity of up to 10,000 DOC so that it offers practicality for cages that have a large population.

C. Drinking water system

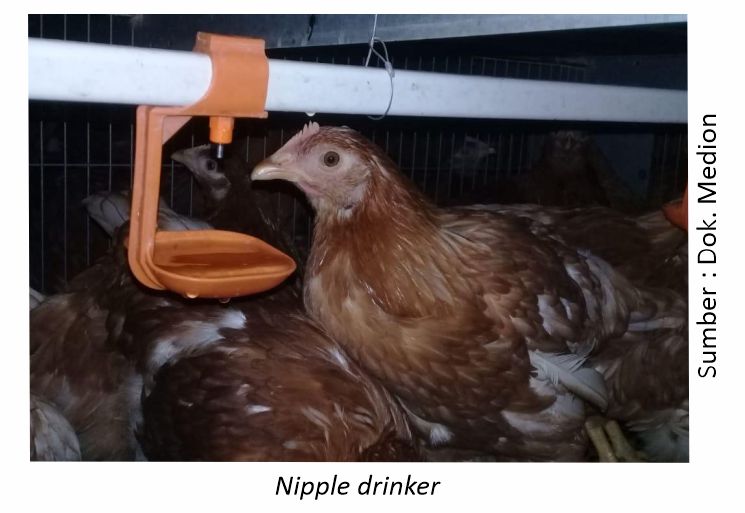

In maintenance with the postal system, all types of drinking places can be used (manual chicken drinking place or nipple drinker). While the maintenance of the battery enclosure system in closed house usually use nipple drinker like NpD-360 with a capacity of 2-4 tail/NpD-360.

But at least still need to provide some fruit in the future starter and grower before entering the battery cage with a capacity of 8-12 tails/NpD-360 so that the chickens are accustomed to use nipple drinker since childhood. Water pipe line height/nipple adjusted to the reach of the chicken (2-3 cm above the head of the chicken).

Treatment nipple drinker or other types of chicken drinkers are washed to keep them clean. Especially for nipple drinker, flushing water pipelines need to be carried out at least once per week or before and after the administration of drugs, vitamins, or vaccines through drinking water.

Drinking water lines that use nipple drinker usually equipped with a water regulator that functions to regulate the water pressure to fit when drinking chicken and water pressure when doing flushing.

D. Feed system

In the type of postal cage, there are three forms of ration places used. First, The Shape of the plate (take care of the DOC/NRDOC) is used for starter. Second, The Shape of the plate and tube form DOC Feeder/DF or Multi Feeder/MF used in starter or where the chicken ration / TRA used in grower and layer. Third, the form of gutters of various sizes that can be used for starter, grower, or layer.

While in the type of battery cage the common form is the feed gutter. Feed distribution can be done automatically. The automatic system is equipped with motors and Feed distribution devices, such as feed hopper or chain feeder. The food is served in a bowl or bowl (hopper) to be distributed to any area in the postal enclosure as well as the battery.

How To Choose Closed House for chicken Layer?

Buildings closed house chicken layer can use walls on all sides of the building, but can also use tarpaulins instead of walls. While steel construction is increasingly commonly used for cages closed house because it offers a faster processing process and a longer service life than traditional materials such as bamboo, wood or concrete. A good cage construction can last 10-20 years.

Cage size closed house adjusted to the number of chickens raised and the maintenance phase carried out. If the phase starter using the postal maintenance system, the need for cage area is calculated by dividing the population by 14 heads/m2, where 14 heads / M2 is the maximum density at the end of the maintenance period. As for the cage cages/ battery, the required area is 200-361 m2 during the lifetime rearing (ISA Brown Cages Product Guide, 2020).

In the phase starter, chickens need warmer temperatures, but with age and weight, chickens need cooling to reduce the heat their bodies produce. To meet the needs of these different chickens, closed house layer usually distinguished for the period rearing/pullet (time for starter – grower) and time layer (time for grower – layer).

1. Phase starter

Chicken coop layer phase starter usually use postal cages, but lately it has become popular colony cages or what is commonly called baby chick or baby box.

2. Grower phase – layer

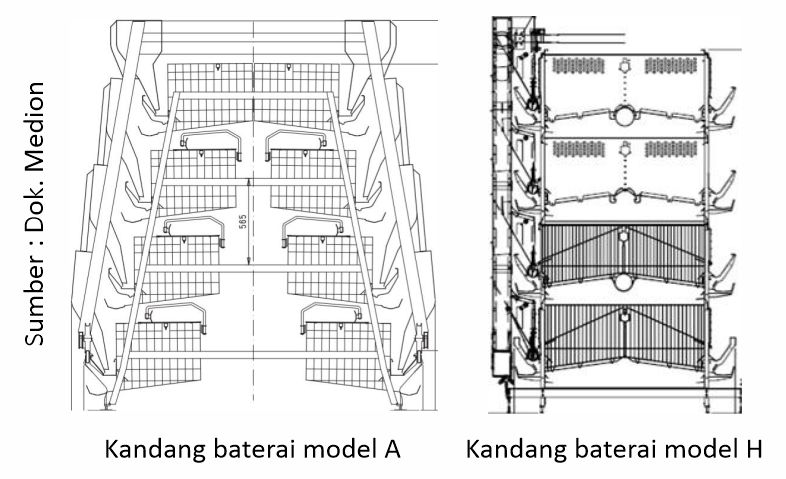

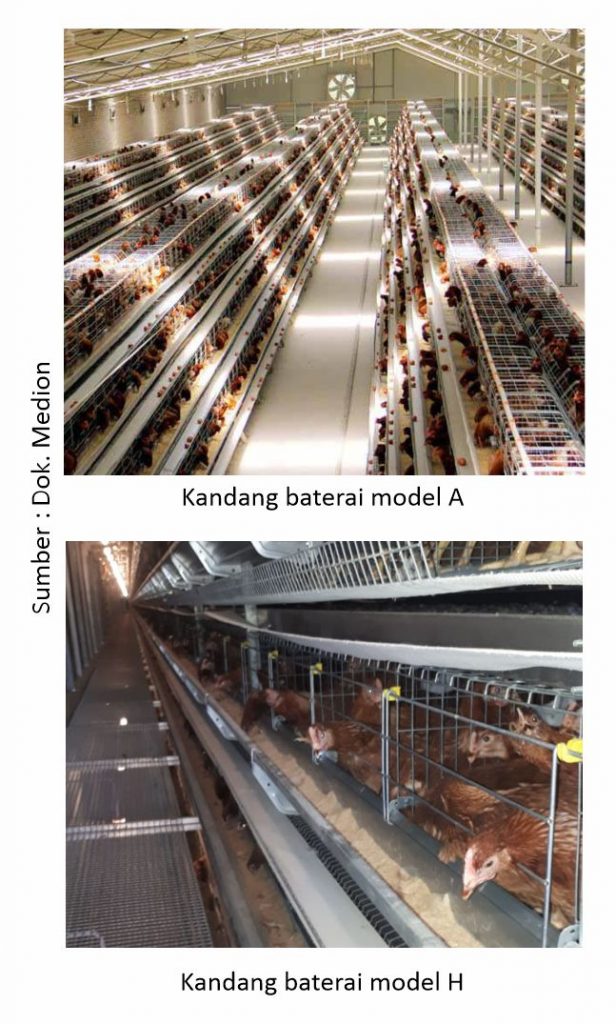

For the phase layer usually use battery cages with various variations, namely Type V, type W, and type AA for cages open house. As for the cage closed house usually use Type A or H cages.

Period rearing it can last until the chickens are 12-14 weeks old. When rearing done with the battery enclosure maintenance system, then the period layer mandatory is also done with the battery enclosure. However, if rearing done with the postal maintenance system, then the phase layer also good with the battery system.

The height of the building must match the specifications and the number of levels of the battery enclosure used. The height of the battery cage with 3-4 levels can reach almost 2-3 meters. In addition to height, the width of the cage also needs to be adjusted.

One line (row) model h battery enclosures are generally over 1.5 meters wide. While the bottom width of the model a battery cage can reach 2 meters and the height depends on the number of levels. The more levels, the wider the battery enclosure will be.

H type battery cage use fecal discharge system with manure belt atau manure scraper. With belt, then the feces will not fall into the battery cage that is underneath because there belt which holds the stool.

Every day or every 2 days, belt will collect feces to the back of the cage for subsequent removal from the cage. Thus ammonia in the cage will be more controlled. While the model manure scraper will clean and collect feces by sweeping or pushing with a scraper.

While the faecal discharge system in Type A battery cages generally does not use belt. In Type A, feces fall and collect in holes made under the battery enclosure.

Battery enclosure closed house has an egg collection system. There is a temporary container system so as to minimize the number of damaged or trampled eggs. Eggs produced by chickens in cages closed house layer it can be collected manually by Cage workers or automatically collected into one area by using conveyor belt or a conveyor belt.

Get the most out of it with nutrition and wellness programs

- Before the start of the period brooding period,, of course, it is necessary to prepare a comfortable and clean cage before the implementation chick in. Cleaning the cage must be done thoroughly from washing the cage, equipment, spending litter and feces, up to liming and disinfection. The rest period of the cage cannot be shortened and should be applied at least 2 weeks after the cage is clean.

- So that nutrients can be met, feed intake (consumption) must enter according to the standard. Provide rations with quantity (amount) and quality (nutrient content) according to the age of the chicken. Make a gradual change of ration and also give supplements Egg Stimulant or Top Mix to supplement the necessary vitamins and calcium. Give form rations crumble or pellet, because chicken layer production prefers to consume rations with a larger particle size than the form mash- flour.

- Water quality degradation must be handled by giving some treatment such as water filtration before channeled to the cage (filtration) and sanitation with antiseptic/ disinfectant. To lower the acidic pH, breeders can mix Netrabil into drinking water.

- Organize the lighting of the cage appropriately. Light in the production period not only serves to stimulate the formation of hormones FSH and LH to form the yolk and ovulation (release of the yolk), but the light also serves to stimulate the appetite of chickens.

- Vaccination programs such as ND, AI, IB, EDS and korisa should have been carried out no later than 2 weeks before the start of production and may be re-vaccinated after passing the peak production period. If at the beginning of the egg-laying period you want to revaccinate, you should first test the antibody titer so that the timing of the vaccination can be determined more precisely and the vaccination must be carried out more carefully.

- Give the medicine according to the attack of the disease. While vitamins should be given regularly as provide Vita Stress and Imustim, especially to cope with stress and improve the condition of the body. Give Asortin to maintain the pH of the digestive tract and kill pathogenic bacteria in the digestive tract. As well as Optigrin which is a mixed feed herbal product to help optimize the health of the digestive tract.

- Sanitation and disinfection; a clean Cage will minimize the challenge of disease seedlings. Disinfection of the cage and the environment also needs to be carried out regularly at least 1 week to minimize the presence of disease seeds that threaten chickens.

- After moving the cage, monitor the condition of the chickens regularly, including the level of ration consumption, temperature and humidity of the cage, weight gain per week until the peak of production, as well as the achievement of egg production.

Usage development closed house, either full closed house or semi closed house more and more every day. The goal is to improve the performance index of chickens so that farmers ' profits are greater. Moreover, the challenges of weather and genetic changes require us to always innovate so that our performance and profits increase. May be useful. Greetings.