In running a broiler farming business, besides being required to pay attention to the critical period, farmers are also required to pay attention to the final stage of maintenance, namely the harvest period. The harvest period will show the success or failure of the cultivation business that we run.

Harvesting activity is the final process of all cultivation activities. The harvesting process will be the final determinant obtained by farmers from the results of business during maintenance. The estimated figure will be calculated by the manager and operator of the cage with the results can be in accordance with the predictions or even miss the projections that have been made.

When can harvesting be done ?

We need to determine the right harvest time to sell chicken meat so that the profit will be known. Here are some important things that can be considered among them:

- Usually broiler farmers have harvested a lot of chickens at the age of 35 days with a live weight of 2.5 kg per chicken. This harvest time can also be adjusted to the time of achieving chicken body weight that consumers like. Household consumers in Indonesia mostly prefer small broilers (1-1.5 kg). While large sizes are usually intended for the purpose of processing certain chicken (satay, opor, etc.) or for the chicken meat processing industry (nuggets, sausages, etc.).

- Fluctuating factors in the selling price of chicken meat on the market can also be a consideration in determining the age of the harvest. The selling price of chicken meat will usually increase on the eve of religious holidays so that the maintenance period can be shortened and sold earlier so that the profits obtained are greater. If the selling price in the market is low, the farmer can extend the maintenance period but still needs to be aligned with the weight of the chicken and the FCR value obtained.

- Feed convertion ratio (FCR) or ration conversion value is defined as a unit value that indicates the ratio between the number of kilograms (kg) of ration consumed by chickens to produce 1 kg of body weight. The greater the value of FCR means the efficiency of the use of rations was getting better, so should. The standard of FCR value is usually determined by the nursery company (breeder) so that farmers can continue to monitor every week.

- Not infrequently, consideration for early harvest is related to disease attacks which result in increased medical costs and ration costs during sick chickens. Not to mention the risk of weight loss and death that can reduce business profits.

Preparation For Harvesting Broilers

Some things to consider in preparation for harvesting broilers are as follows:

- One week before harvesting, give the cage lighting for 24 hours so that the chickens always eat and drink, so that the expected chicken weight is obtained.

- Check the last available chicken stock report in the coop and take some chicken samples first to be weighed per individual. This Data will be used as a benchmark value/control of the overall report on the weight of the chicken to be harvested.

- Pay attention to the downtime of the drug at least 5-10 days before the chicken is harvested (can be adjusted to withdrawal time of the type of antibiotic administered). This is to avoid the presence of antibiotic residues in chicken meat products. As for vitamins, they can still be given. In addition, the administration of antibiotics will also only spur the work of the organs to be heavy so that the chicken will not withstand the physical stress experienced.

Implementation Of The Harvest

As for us, we will-review back procedure on the day of the implementation of a good chicken harvest is:

- For harvesting time it would be better if the chickens are caught in the morning, afternoon, or evening so that the chickens are not so stressed. Where at that time the intensity of heat from the sun is not so high, and the ambient temperature of the cage is also quite low. For catching at night, try to keep the lighting using dim lights to make it easier to catch. Due to the nature of chickens tend to be silent in dim or dark conditions.

- Do not give rations full in chickens, 12 hours or at least 8 hours before the chicken is harvested so that the rest of the ration is not wasted because it is not digested. After cutting, of course, there will be a lot of leftover feed that is still in the cache. Livestock given feed shortly before harvest will also have a high weight when weighing. However, the risk is a large shrinkage when re-weighing occurs in depots or at poultry slaughterhouses or RPUs, because the feed eaten does not have time to be completely consumed by chickens. But farmers can still provide regular drinking water or vitamin drinking water to chickens.

- When the chicken transport car arrives, spray disinfectant on the car along with the basket to minimize disease transmission.

- Prepare cage workers or capture teams according to their needs and are used to struggling with chicken harvesting activities.

- Prepare harvesting equipment such as scales, stationery, letters, notes scales, raffia rope, chicken baskets, and flashlights to help lighting if the harvest is done at night.

- Remove the ration and drinking places so as not to interfere with the activities of workers during the capture of chickens.

- Make the chicken insulation gradually according to which chicken will be caught first so that other chickens that have not been caught do not go limp. Bulkhead can be made with a size of 7 x 3 meters or as needed. In addition, when creating bulkheads, avoid stacking (over lapping) chicken in the corner of the cage and do not be too dense so that many chickens do not die.

- Before weighing, the scales should be calibrated first to prevent miscalculations that can harm the farmer.

- When harvesting, generally each cage worker can hold 3-5 chickens at a time. After being caught, both chicken legs are tied with a rope so that they can be weighed in groups (about 3-5 at the same time) and immediately record their live weight, since the selling price of chickens broiler will be calculated per kg body weight Life Time. Spend chickens in one block, do not use the catch Select system to catch chickens while harvesting.

- Avoid catching the chicken roughly and holding one of its wings first, because the chicken will rebel and as a result the wings will bruise and the chicken will be stressed.

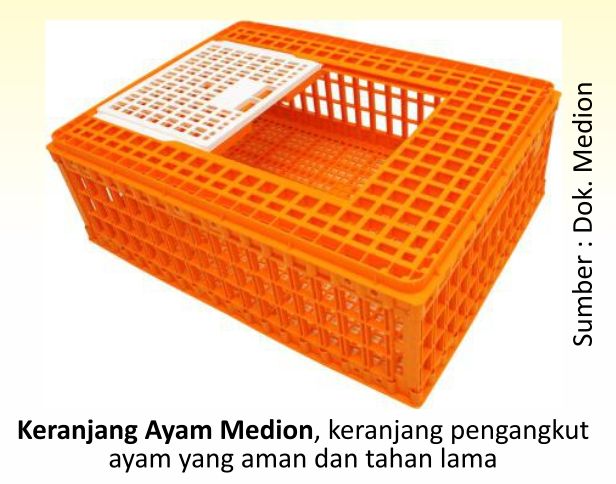

- After weighing, put the chicken in the chicken basket and avoid rough action to reduce the risk of many chickens being diafkir due to broken wings or legs. The baskets containing the chickens are then loaded and placed in the transport truck.

- Adjust the capacity of the chicken basket with livestock scales. The capacity of the chicken carrier basket assuming the weight of 1 chicken 1.6-1.8 kilograms can accommodate 18 tails per large basket and for a small basket of 1.4-1.8 kilograms can accommodate 8-10 tails. If it is more than that, then the risk of death during transportation will be high. Use a quality chicken carrier, such as Medion Chicken Basket.

- Re-check the condition of the chicken after the capture is complete. Also, the results of the scales data that has been obtained so that there are no miscalculations.

- After all the data is correct and in accordance with the arrest warrant, then the chicken transport vehicle may be allowed to leave the location of the cage to go to the collector or directly taken to the slaughterhouse.

- The length of time between the time the chicken is put into the basket until it is cut, and the high temperature of the air around the basket will affect the amount of weight loss and death. For this, the time of transportation of chickens and the length of the distance traveled also need to be taken into account. Keep in mind the shrinkage at the time of Transportation ranges from 1-3%.

Harvesting is the final factor determining the income of a farming business. The value of FCR is only limited to predictive numbers that can still change. Therefore, a good harvest will greatly affect how much profit will be obtained.