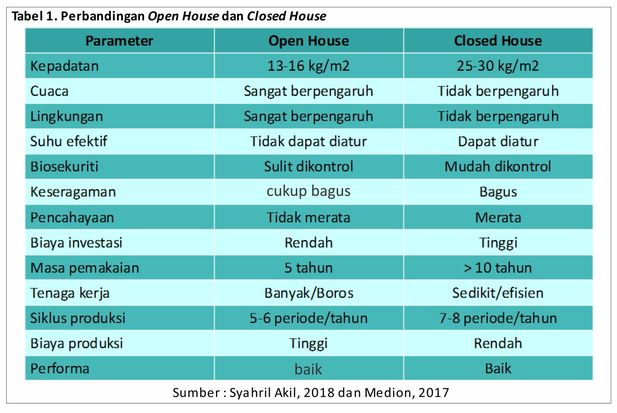

Cage development closed house very rapidly in Indonesia, the percentage has reached 25% of the total chicken coop. A remarkable development. Can be predicted in the future, the construction of cages closed house will be increasing.

Closed House is…

Closed house or a closed Cage is a cage system that is able to provide quality air, both in terms of composition, speed and the right amount so that the chicken is comfortable. This closed enclosure will minimize the influence of environmental conditions that are currently very volatile.

The main principle of closed house is to provide comfortable conditions for livestock by removing heat from the cage produced from the body of chickens, lowering the temperature of the incoming air (if necessary), regulating the humidity accordingly and removing gases that adversely affect it, such as carbon dioxide (CO2) and ammonia (NH3). And all these processes can be set automatically. This convenience is often one of the interesting considerations for changing the cage open house (the cage is open) closed house.

Choosing Considerations Closed House

Closed cages require a greater investment cost than open cages. Despite this, many breeders have switched to using closed cages. Some considerations turn to cages closed house include:

- Improved performance

Improved chicken performance is the most powerful reason to change the cage from open house to closed house. This is what often makes farmers change their minds. Chicken productivity is increasingly difficult to achieve optimal, making farmers look for solutions to achieve this. And one of them is to make the cage as comfortable as possible` for chickens. The hope is that when the conditions are comfortable, the chicken cage will be able to optimally produce eggs and produce a high percentage (up to 96% and last a long time).

Performance Index (IP) of chicken broiler when using cages open house range 260-370 while when the cage is converted into closed house can increase to 400-420 (Trobos, 2018). The higher the achievement of IP then the farmer's profit will be greater. For comparison, when using a cage open house broiler chickens harvested in umuar 30 days weighing 1.8 kg and feed conversion ratio (FCR) 1.52 – 1.53 while when kept in closed house cages with the same Harvest age,body weight can reach 2-2.1 kg with FCR 1.5 (Trobos, 2018). In other words, chicken performance increases with better feed efficiency.

- Increase cage capacity

The density of open house cages ranges from 13-15 kg/m2 and when using a closed house, the density of the cage will increase by almost 2x, reaching 25-30 kg/m2. This of course will minimize the need for land that is currently increasingly difficult and expensive to find. Moreover, there have been many cases of closure of cages because they are adjacent to residential areas. This increase in capacity is further increased when the cage is made multilevel, both two and three levels.

- Uncomfortable environmental conditions

Intergovermental Panel on Climate Change (IPCC) said that the global average temperature on the Earth's surface has increased 0.74 + 0.180C for the last hundred years. And it is estimated that global surface temperatures will increase from 1.1 to 6.40C between 1900 and 2100. This means that the ambient temperature of the cage will increase and erratic weather patterns.

Increased ambient temperature will greatly affect the achievement of chicken performance, both broiler or layer. Moreover, chickens do not have sweat glands and are very sensitive to temperature changes. This is what causes farmers to switch to using closed house.

The use of closed cages will overcome the effects of rising and fluctuating ambient temperatures. The fan (exhaust fan) and cooling pad will be able to modify the temperature and humidity of the air in the cage so that it is comfortable for the growth of chickens.

- Eco-friendly

Chickens kept in closed cages become more comfortable. This will affect the quality of the dirt removed. The feces become drier. Moreover, the existence of exhaust fan more or less will help improve the quality of feces. The presence of flies can be further suppressed.

A Closed Loop (Closed House)

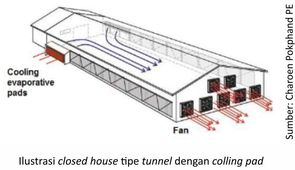

Type closed house divided into 2 based on the direction of air movement, namely the type tunnel (tunnel) and cross flow.

- Closed house type tunnel

This type is the most widely used in Indonesia. Tunnel or tunnel, this type of closed enclosure is described as a tunnel where air will enter from the front (inlet) and will be pulled back flowing along the enclosure and removed with the aid of exhaust fan.

Type tunnel this is also divided into two, namely tunnel by using cooling pad (full closed house) and without cooling pad (semi closed house). Usually full closed house used for areas with low humidity levels and high temperatures. While semi closed house it is usually the result of a modification of an open cage and is located in areas with high humidity, such as in areas with high rainfall in Bogor. This type of Cage is usually used for adult chickens.

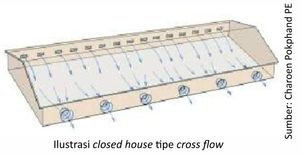

- Closed house type cross flow

Exhaust pan mounted along the sides of the cage, and inlet on each opposite side, so that the air moves perpendicular to the length of the building. This type produces low wind speeds and is widely used when chicks and in low temperature areas.

Fittings Closed House

The ventilation system becomes the main thing of a closed house. The completeness of this ventilation system consists of fan (fan), evaporative cooling pad, controller and the cage curtain.

- Fan (fan)

Fan (fan) it is a device for air movement. In general, there are 2 types of fans, namely exhaust fan and blowing fan.

Exhaust fan serves to suck the wind and blowing fan serves to blow the wind. Thrust blowing fan very limited, ie a maximum of 12 meters by blowing fan 36 inch capacity 20,700 m3/ hour at a pressure of 50 Pa. Therefore the system closed house , conducted via exhaust fan.

The parameters that need to be considered in the operation of the fan are the number of fans on and the length of time the fan is on. The selection of the right fan is necessary in order to produce the appropriate air speed and temperature with minimal electrical power consumption.

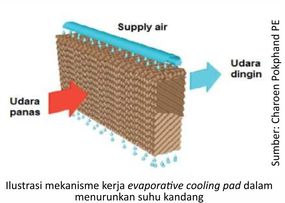

- Evaporative cooling pad

Evaporative cooling pad an air conditioner that utilizes the evaporation of water. Evaporative cooling pad connected to a pump that will wet it with water. When hot air from outside the cage enters cooling pad, the water will take heat energy from the air so that the water will evaporate (evaporation process) and result in a decrease in the temperature of the air entering the cage. Breeders are not recommended wetting cooling pad when humidity >75%, because it will increase the humidity of the cage.

Evaporative cooling pad also serves as a filter for air entering the cage. Block-block cooling pad prevent air impurities (large) to enter the cage, so that the incoming air becomes cleaner.

- Controller

Controller atau disebut climate controller is a device for controlling the temperature and humidity in the enclosure. This tool is often referred to as his “brain” closed house. This Controller can be programmed in such a way with the target of making the atmosphere of the cage, the temperature and humidity comfortable for chickens. Controller will set on or off the fan or pump on evaporative cooling pad.

- Curtain cage

The cage curtain is the side cover of the cage so that the chickens are protected from outside interference. In addition, cage curtains are also useful for :

- Helps maintain the air temperature in the cage (especially during periods brooding period,)

- Prevent direct wind exposure to the chicken's body

- Prevent rainwater splashing

- Provide emergency ventilation in case of power failure (Dead fan)

- Generate the required static pressure in the system closed house

Cage curtains combined with the system winch (pulley), to facilitate the rapid raising or lowering of the curtain, it is enough with an operator.

Mechanism of temperature drop on Closed House

The temperature detected on the thermometer is often confused with the temperature felt by the chicken's body. Though it is not so. The temperature felt by the chicken's body is called the effective temperature. This effective temperature is influenced by 3 factors, namely room temperature (the temperature detected in the thermometer), humidity and airflow speed in the cage (which hits the chicken's body).

Air humidity (relative humidity or RH) is the level of water vapor contained in the air. Humid air (containing a lot of water vapor) will inhibit the rate of evaporation from the chicken's body, so that the temperature felt by the chicken will be higher than room temperature (thermometer temperature).

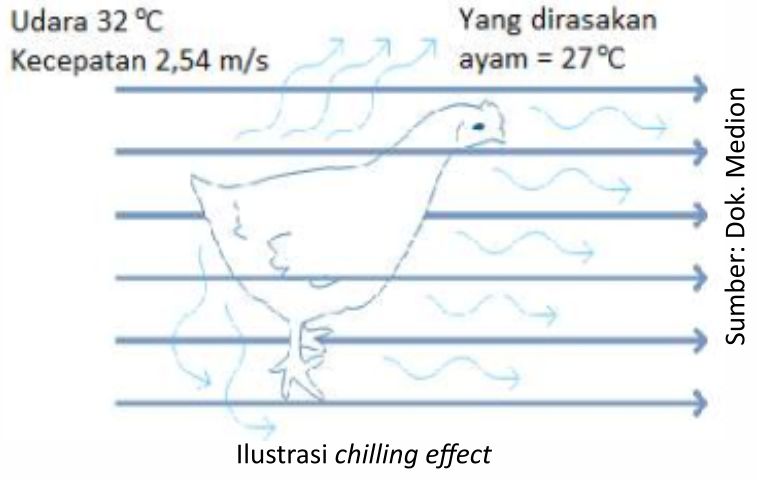

Although the thermometer temperature is high, but if there is air flow, the temperature felt by the chicken's body will be lower. This is what is called chilling effect.

Chilling effect is the effect of a decrease in temperature felt by chickens due to the speed of the wind that blows. The tool that plays a role in this effect is the fan. The higher the wind speed, the chilling effect perceived greater or lower effective temperature. It's just that the wind speed that hits the chicken's body needs to be taken into account. For chicken broiler the recommended wind speed is 0.3 m / sec at the time of brooding period, and 3 m / sec when age > 28 days.

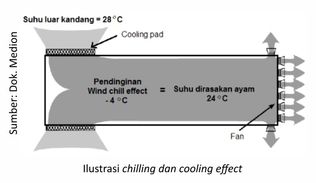

When dry environmental conditions, where the air humidity is low (low RH) use evaporative colling pad will help lower the air temperature in the cage and the temperature felt by the chicken's body. Decrease in air temperature by utilizing the process of evaporation of water is called cooling effect.

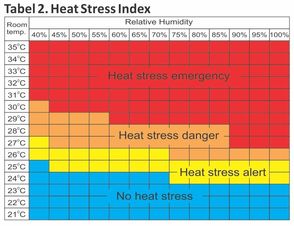

Heat stress index is a parameter that can help us to see the comfort of the air in the cage. This index is a correlation between the temperature and humidity of the enclosure. Safe limits heat stress index for chicken broiler it was 85-95. Formula heat stress index is the sum between temperature (0 C) and humidity (%). Table 2 shows heat stress index.

Determinants Of Success Closed House

Closed cageclosed house) is a modern cage with various facilities that make it easier for farmers to manage chicken rearing. Starting from the temperature and humidity settings that can be done automatically, until the ration and drinking water is all automatic.

This much ease often makes breeders take cage management lightly closed house. As a result, not a few farmers who fail and even go bankrupt due to management closed house which is not optimal.

- Make sure the power supply is always available

Electricity is a major requirement in sometimes closed. All closed house appliances require electrical power. Install electrical installations well, calculate all electrical power requirements.

Prepare genset to replace the electricity supply from PLN that suddenly dies. Always check the condition genset in the cage. Make sure genset always ready to light up. Sometimes farmers lulled by the current electricity supply PLN so that care genset forgotten. As a result, when PLN electricity dies then genset it can not ignite, so the chicken will lose air supply. And not a few cases of total chicken death can occur during a power failure.

At the time of power failure and genset can not replace, the solution is to lower the cage curtain manually. Or it can also be done automatically by using the tool emergency curtain drop which is usually installed on each side of the curtain cage close of the curtain cage pulley.

- Early detection of indications of disease attacks and overcome immediately

Increased cage density with dimmer light intensity than open house requires us to always be more alert to the onset of disease. What's more, the air circulation system that allows disease attacks to spread more easily, especially respiratory diseases.

Always monitor the health condition of chickens regularly. Immediately separate chickens that are detected weak or have disease. Perform routine antibody titer monitoring so that the available antibody titer data can be used as early warning system or early warning of a disease attack.

Closed cages for laying hens, especially during production, must be very careful and always increase vigilance against disease attacks. Moreover, the intensity of light when the production period is relatively low (dim light) with colony cages containing 6 tails makes us have to be more observant in identifying chicken conditions.

- Changing the paradigm of employee housing

Cage employees involved in closed house must be equipped with special management. Choose people who want to change themselves to adjust to the conditions closed house. Some cases found employees sometimes feel working in a closed Cage is more comfortable than open house. And this condition often makes them complacent. Though the challenge of maintenance in the cage closed house can be said to be more complicated than open house, even more so when a case occurs.

Employees should be divided into several parts, ranging from the maintenance of chickens and employees of the maintenance of cages and equipment. The two must be separated. Needs skill or the skill of each piece is very different.

Knowledge and skills of cage personnel must always be in-up grade (above) and in-updates (get the latest info) periodically. Hope every new challenge and problem in closed house can be handled quickly. Moreover, this cage employee is the most important line that is directly related to the condition of the cage.

Medion as a national poultry company is always ready to assist customers in terms of consulting about closed house or updates management of rearing and diseases in chickens. It is accommodated by organizing training for farmers Medion which is routinely held every 1 month as well as Lecture activities by Medion field team.

Closed house is a stepping stone to modern chicken rearing technology. This is an inevitability. The development of farmers who use closed house, good full closed house and semi closed house more and more every day. The goal is to improve the performance of chickens (performance index) so that the farmer's profit is greater. Weather forecast (global warming or global warming) or genetic changes require us to always innovate so that our performance and profits increase. Happy move. Greetings.