Mr. Amin Justok – By email

Dear Sir/Madam, in my place, all the rice bran is mixed with husks, causing many eggshells to be pale and cracked. After using Betterzym in the feed mixture with 15% inclusion of rice bran (mixed with husks) in the formulation, the number of pale and cracked eggs decreased.

What is the maximum percentage limit for giving rice bran mixed with husks without administering Betterzym and with the administration of Betterzym?

Answer:

Thank you, Mr. Amin Justok, for your question. Rice bran is a by-product of the process of milling paddy into rice. Rice bran is produced from the first polishing of hulled rice, while fully polished rice that goes through the second polishing process will yield rice, broken rice, and rice polish/fine bran.

A grain of paddy or dry rice that goes through the milling process can produce 20% husk, 6-11% rice bran, 2-4% fine bran/polish, and 60% endosperm (rice) (Rachmat et al., 2004). By standard, rice bran is an energy source raw material that contains nutrients such as a maximum Moisture Content of 12%, a minimum Crude Protein of 12%, a maximum Crude Fat of 15%, a maximum Crude Fiber of 11%, Calcium 0.04-0.3%, Phosphorus more than 0.6%, and a minimum Metabolizable Energy of 2,400 Kcal/Kg (Asian Poultry, 2016).

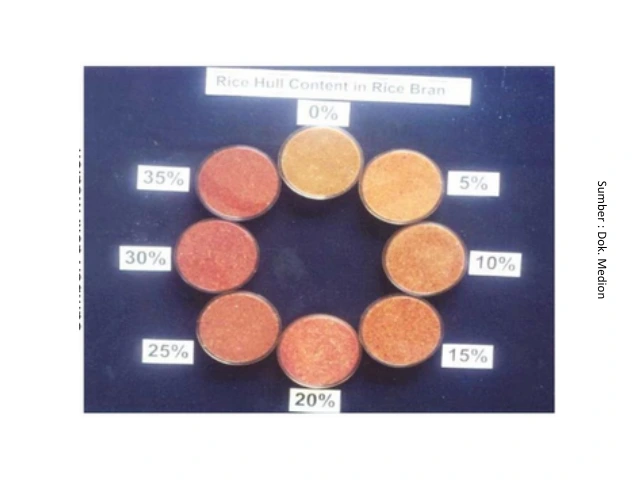

Physically, rice bran is characterized by a light brown color, a flour-like form, a fine texture, and a distinctive bran odor. The use of rice bran in feed is usually around 10-20% (Feed Reference, 2003).

Factors Limiting Rice Bran in Feed Formulation

Although it has a fairly high content of protein and metabolizable energy, there are several factors that can limit the use of rice bran in feed formulation, namely:

1. Contamination or adulteration

Some of the most frequently encountered adulterants in rice bran mixtures are rice husks and rock flour/limestone powder. Firstly, contamination can be found in rice bran due to a poor milling process where the husks are not separated properly or when rocks are accidentally included during milling.

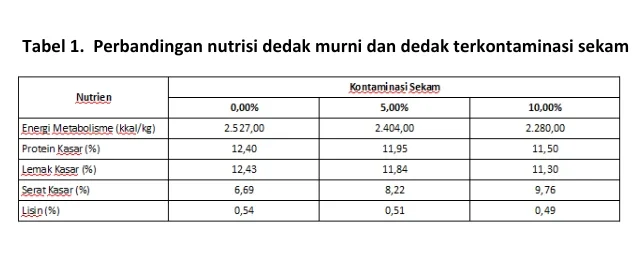

However, there is sometimes also deliberate action by sellers to intentionally include these two ingredients due to their similar physical characteristics. This can reduce the nutrient quality of the feed ingredient. Quality control needs to be carried out to check for adulterants. The following is a comparison of the nutrient content between pure rice bran and that contaminated with husks.

2. Fairly high crude fiber content

According to the Indonesian National Standard (SNI) in 2024, the maximum amount of crude fiber content of rice bran for quality I, quality II, and quality III is $12\%$, $15\%$, and $18\%$, respectively. Generally, high crude fiber in rice bran can be caused by a mixture of husks in the feed. Rice husks have an unbalanced nutrient content, namely very low protein and high crude fiber content.

The nutrient composition of rice husks is a crude protein of 2.9-3.6% and crude fiber of 39-42% (Oyenuga, 1938). Crude fiber components such as hemicellulose, cellulose, and lignin cannot be digested by poultry such as chickens because the chicken's body does not produce the enzymes that digest them, such as the enzymes hemicellulase, cellulase, and lignocellulase.

3. Antinutritional content in rice bran

- Antinutrients are substances naturally present in plant-based feed raw materials that can inhibit the growth, development, and health of livestock due to disruption of the nutrient absorption process in the digestive tract. Rice bran has antinutritional substances such as phytic acid and trypsin inhibitor.

- Phytic acid is an antinutritional compound in feed ingredients that can bind amino acids at acidic pH and minerals, especially phosphorus at neutral pH in the poultry digestive tract such as chickens. A lack of phosphorus content in the chicken's body can cause calcium absorption to be disrupted, which can lead to paralysis, thin eggshells, or cracked eggshells.

- Trypsin inhibitor can inhibit the process of protein breakdown by trypsin. Trypsin is an enzyme that functions to break down protein into peptones. The trypsin inhibitor can result in suboptimal growth and production due to amino acid deficiency. The amount of trypsin inhibitor can be reduced by heating, however, care must be taken because excessive heating can cause damage to other nutrients such as amino acids or vitamins.

Ways to Control Rice Bran Quality

To control the quality of the rice bran used, the following methods can be done:

1. Feed ingredient quality control

- Conduct routine quality checks of raw materials and feed. Checks can be carried out by organoleptic or physical and chemical tests. Testing can be done every time feed ingredients arrive or when there is a change of supplier.

- Organoleptic testing can be done by examining the color, aroma, and texture. Rice bran should have a light brown color, not have a rancid aroma, and a fine texture. An easy way to detect adulterants such as husks is the hand-clench test. When clenched, the rice bran should not immediately crumble and should still hold a clump shape.

- Through chemical testing, the minimal parameters that should be tested are crude protein, crude fiber, and metabolizable energy content. The minimum crude protein content is 12%, maximum crude fiber is 7%, and minimum metabolizable energy is 2,400 Kcal/kg. Chemical testing may take a little longer if carried out. However, there are two practical chemical methods to detect adulterants, namely the Phloroglucinol test to check for the presence of husk contamination and the carbonate test to check for the addition of rock flour/limestone powder.

- The Phloroglucinol test can be done by dropping a little Phloroglucinol solution (approximately 3-5 drops or until the rice bran sample is fully covered by the solution) onto the rice bran. The solution will turn the lignin content in the feed ingredient red. If a red color appears, it is indicated as the presence of husks in the feed ingredient. The redder the color, the more husk contamination is indicated in the feed ingredient.

- Meanwhile, the carbonate test is carried out by adding 1:1 HCl solution to the rice bran. If bubbles appear, it is indicated that there is rock flour/limestone powder in the rice bran. The more bubbles that form, the more rock flour/limestone powder is added.

2. Feed storage management

Pay attention to the storage period because rice bran has high porosity or is hygroscopic, making it easy to absorb and release water. Good rice bran should have a moisture content below $12\%$. If the rice bran has a high moisture content, it will accelerate the rancidity process which causes a rancid odor and will reduce the palatability of the feed ingredient (the livestock's preference for the feed ingredient). Pay attention to the following storage management:

- Arrange the stack of rice bran sacks in the warehouse

Use pallets under the stack of rice bran sacks. Try not to let the sacks directly touch the floor or walls of the warehouse. Keep a minimum distance of $50 \text{ cm}$ from the warehouse wall. Set the height of the pallet stacks at $5-15 \text{ cm}$ with a maximum height of 3 pallets, and each pallet contains 6 stacks. This aims to increase circulation and prevent the rice bran from absorbing water from the floor.

- Control the temperature and humidity of the storage warehouse

A good warehouse has a temperature ranging from 30-34°C with a maximum humidity of 70%. Humidity can also be controlled by ensuring there is ventilation in the warehouse to regulate air circulation so that the warehouse is not damp.

- Implement the FIFO (First In First Out) system

This system is carried out by arranging the storage layout so that the rice bran that arrived first can be used first.

3. Use enzymes to improve the quality of feed ingredients

- In addition to being affected by the presence of husk contamination, the quality of rice bran can also be affected by the antinutritional substance in the form of phytic acid. Phytic acid is a substance that can inhibit the absorption of rice bran nutrients in the digestive tract because it can bind amino acids such as arginine, lysine, and histidine at acidic pH. Meanwhile, at neutral pH, phytic acid will bind minerals, mainly phosphorus. This can cause the eggshell quality to be compromised. The use of poor-quality rice bran can be accompanied by the administration of Betterzym , which contains the enzyme phytase. The phytase enzyme plays a role in breaking the bond between phytic acid and amino acids or minerals so that their availability can be maximally absorbed by the digestive organs. Betterzym can be used at a dosage of 1 kg/ton of feed for broilers, ducks, and pigs, 0.6 kg/ton for layers and laying ducks, and 0.6 kg for breeder livestock.

- The limit for using rice bran containing husks, if without using Betterzym , should be a maximum of only 10%. Meanwhile, if with using Betterzym, rice bran can be used up to 15%.