Air Particles/Dust inside the Cage (atau Air Particles/Dust inside the Coop)

Air particles/dust/particulate matter (PM) are major environmental stressors in poultry houses. Airborne particles can absorb and carry various pollutants, including heavy metal ions, ammonia, and organic pollutants such as pathogenic microorganisms.

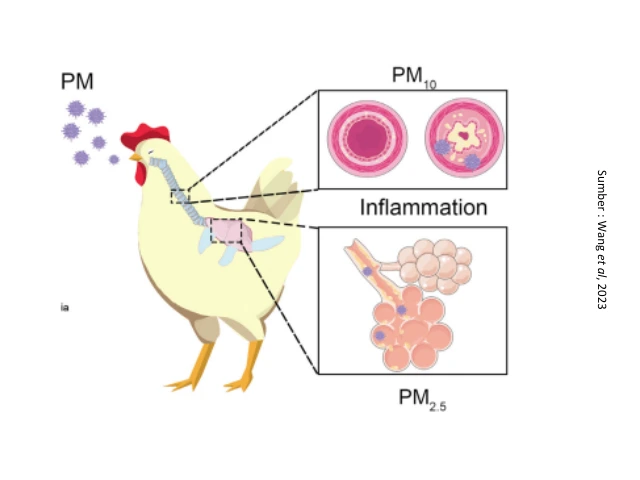

Air particles are generally divided into two types based on their size: PM10 and PM2.5. PM10 refers to the larger suspended particles with a size of <10 micrometers ($\mu$m), while PM2.5 refers to the smaller airborne particles with a size of <2.5 micrometers ($\mu$m).

Air particles can originate from feed, litter, feces, feathers, dander (dead skin), dust, mite waste, and microorganisms such as bacteria, fungi, and endotoxins (bacterial cell wall components). Dust is often overlooked inside the coop/cage because it tends to be less visible and is considered to have no impact on the chickens.

Impact of Air Particles inside the Cage

High concentrations of air particles can cause inflammation of the chicken's respiratory tract and lead to various diseases, thereby reducing productivity. Not only that, high concentrations of air particles can endanger the workers inside the coop/house. Airborne particles can cause damage to the human respiratory tract, leading to symptoms such as coughing, sneezing, chest tightness, sore throat, and if exposed for too long, can even cause cancer.

The accumulation of dust and contaminant microorganisms on the surface of the chicken's respiratory tract will result in damage to the respiratory tract. Inside the chicken's body tissues, the dust will subsequently be eliminated by phagocytic cells (part of the white blood cells). Phagocytic cells that are repeatedly used will cause the chicken's immune system to decline because the body's defense system via white blood cells is not in optimal condition.

In carrying out phagocytosis, phagocytic cells require a certain amount of energy, thus reducing the energy used for egg production and causing the FCR (Feed Conversion Ratio) to increase. (or FCR to worsen/swell). Subchronic to chronic inflammatory reactions in the epithelial lining of the chicken's respiratory system will cause epithelial cell death, or apoptosis. This condition will clearly facilitate secondary infection by pathogenic microbes present in the shed air.

Factors Affecting Air Particle Emission

The adverse effects of dust on chickens and humans are one of the challenges that farmers must face. Farmers must understand the causes of high dust levels inside the coop/house and maintain healthy air quality to support chicken productivity.

The air quality inside the coop/house is strongly influenced by the amount of air particle emission. The following are some factors that influence air particle emission:

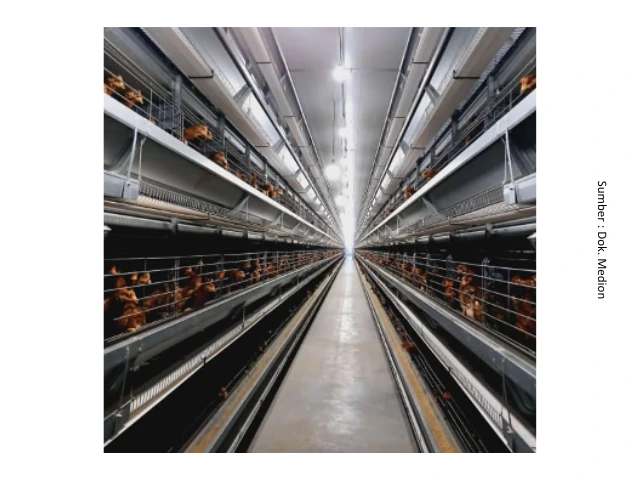

1. Type of Coop/House

The type of poultry house/cage is a main source that influences air particle emission. Various cage types include aviary, conventional (battery), and enriched colony. These different cage types will produce varying air particle emissions. Aviary-type houses will produce a higher concentration of air particles compared to other types. The daily air particle concentration level in aviary houses is 6–9 times higher when compared to conventional and enriched colony cage types.

Indirectly, aviary houses carry a higher concentration of airborne bacteria, and these air particles also act as carriers for the bacteria in the air. The aviary house implements the principle of animal welfare, which results in higher activity inside the house, consequently increasing air particles in addition to feces and feathers, which further raise the dust concentration inside the house.

2. Bedding/Litter Material

Aviary houses typically use litter on the floor so that the chickens can express dust bathing and scratching/pecking behavior. Litter in an aviary house covers at least 1/3 of the total area in a closed house layer cage. Litter is a primary source of air particle emissions.

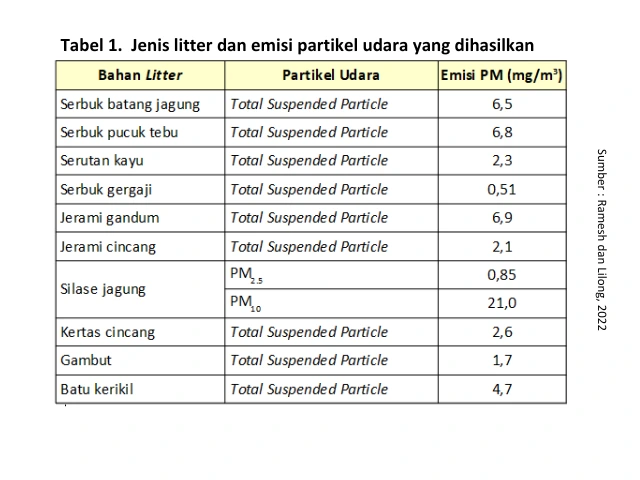

Air particle production from litter can be affected by the type of litter, litter moisture, litter thickness, and the frequency of replacement or cleaning. The types of litter that can be used may be organic (husk, wood shavings, sawdust, paper) or inorganic (sand, and clay) and must be non-hazardous/non-toxic, easy to absorb water, comfortable for the chickens, and easily available. Litter is checked regularly by grasping it in one's hand. The types of litter and the resulting air particle emissions can be seen in Table 1.

3. Lighting Effects

Sufficient light intensity will lead to increased chicken activity, which consequently impacts the concentration of air particles. Ramseh and Lilong (2022) state that chickens are very active during lighting hours, and with the application of maximum ventilation, the emission of air particles inside the house will increase. Air particles will decrease at night due to low activity at night resulting from reduced light intensity.

4. Season and Environmental Humidity

Air particles inside the closed house layer cage are more abundant in the dry season compared to the rainy season. In the dry season, relative humidity tends to be lower, which can cause the litter to become drier. Overly dry litter is more likely to generate dust when chickens move or when there is air movement from circulation or when the ventilation system is operating.

When maximum ventilation is used to lower the temperature inside the house, it will cause more dust to be lifted. In the rainy season, relative humidity tends to be higher, which prevents the litter from becoming too dry and results in a relatively smaller amount of air particle emissions.

5. Manure Management

Manure management plays an important role because manure contributes about 50% of the total air particle emissions inside the house. Chicken droppings that dry inside the house can decompose into fine airborne particles. Manure accumulated on the floor/raised floor/collection system (manure belt or scraper) will produce a lot of dust, especially if it is not cleaned immediately.

Chicken manure also carries bacteria and microorganisms trapped in the dust. Proper manure management will significantly reduce air particle production inside the house. Chai et al. (2012) stated that the manure management system in raised A-frame houses (high-rise) has higher air particle concentrations compared to manure belts and scrapers.

Manure in raised A-frame houses will accumulate for a long time, causing it to dry out and decompose into dust. The frequency of removal in manure belts and scrapers prevents the buildup of feces and helps reduce dust formation. The manure belt can be operated once a day, and the scraper can be operated twice a day.

6. Chicken Age and Stocking Density

Older chickens will generate more dust due to higher activity compared to pullets. Older chickens have stronger movements, making it easier for droppings and particles from the bedding/walls/battery cages to be lifted into the air. Feather production in older chickens tends to involve more feather shedding.

Particles from shed feathers contribute to the increase in air particles. Similarly, with stocking density, the more limited the chickens' moving space is, the more they tend to crowd together, which causes more air particles to scatter.

Measuring Air Particle Levels

Air particles can be measured using the Gravimetric sampling method. Sampling with the Gravimetric method uses a small pump to draw air through a filter paper disc, trapping large air particles as well as those from the filter pores. The Gravimetric method requires several hours for a sufficient amount of dust to settle on the disc, so this method does not provide real-time measurements.

Another method, the Optical Particle Counter, works by measuring the amount of light passing through an air sample containing dust in real-time. The Optical Particle Counter is less accurate compared to the Gravimetric sampling method but is useful for measuring air particles and making comparisons over time.

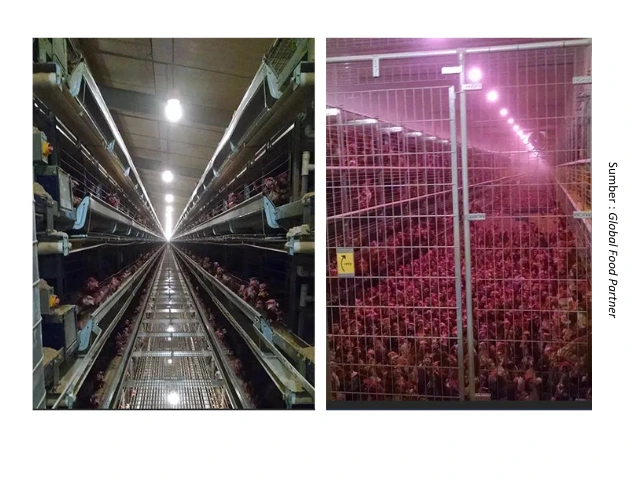

Sometimes, farmers face cost constraints in providing equipment such as Gravimetric and Optical Particle Counters. Simple observation can be done using the sense of sight. The eye should be able to clearly see the house area for more than 30 m. If you see a cluster of dust and it looks hazy, it can be confirmed that the air particle level is above the standard limit. The difference in appearance between a clean house and a hazy house can be seen in Figure 3.

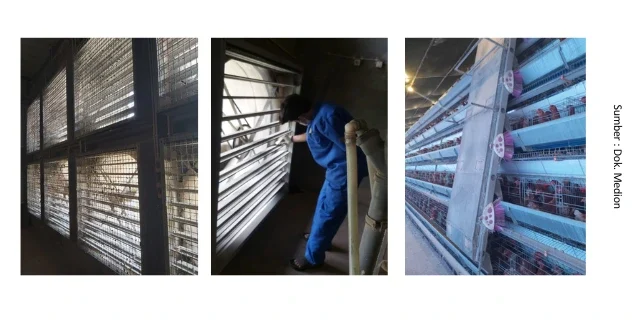

Another simple way is to use light assistance. A cell phone flashlight can be used to see particles in the air. If dust is seen floating when exposed to the flashlight or torchlight, the house likely has an air particle problem. Another way is to observe the surfaces of objects such as the exhaust fan, cooling pad, and battery cages.

For example, dust accumulation in the ventilation system, especially the shutter and blade, can reduce the performance of the ventilation. The fan's performance/capacity will decrease, and the consequence is that the air exchange in the house will also definitely decrease. Furthermore, excessive dust accumulation on the shutter can cause the fan shutter to tend to remain closed, leading to an increase in negative pressure inside the house, so the dust in the house will also become more concentrated. Therefore, object surfaces in the house must be regularly cleaned and maintained.

Air Particle Control

Air particle control in the house must be carried out to avoid adverse effects on chickens, humans, and ventilation equipment. The more it is ignored, the more it will erode the profits gained by the farmer. The following are air particle control measures in the closed house layer cage:

1. House cleanliness and routine equipment maintenance

Routine cleaning is crucial in controlling air particles in the closed house. Regular cleaning helps reduce the accumulation of air particles from feces, feathers, and feed. Before rearing, all areas inside the house (walls, floor, equipment, roof, curtains, battery cages) must be ensured to be clean.Equipment in all systems within the closed house must be cleaned daily from litter, feathers, leftover feed, manure, and broken eggs to minimize air particles spreading inside the house. Ventilation system equipment in the closed house, such as the cooling pad and exhaust fan, must also be cleaned of dirt because it can affect ventilation inside the house. Equipment maintenance, such as checking the condition of the pulley, blade, and fan belt on the fan and checking the cooling pad, must be done when the house is empty and during chicken rearing.

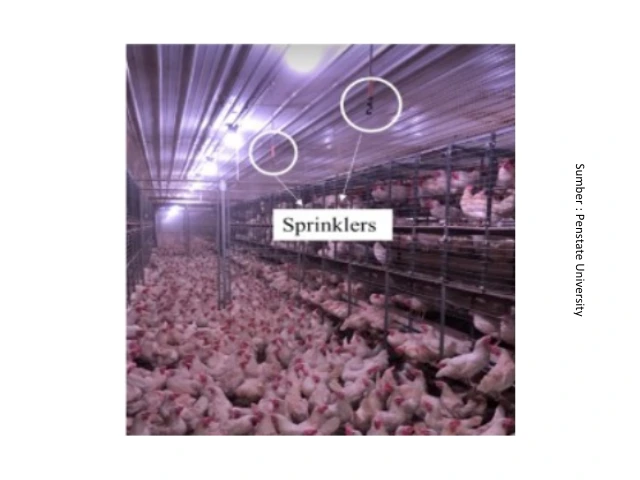

2. Spray (Water and Oil)

Spraying with water and oil inside the closed house layer helps control the concentration of air particles indoors. Research has been conducted on spraying liquids such as water, acidic water, or a combination of water with vegetable oil (canola oil or soybean oil) or mineral oil (paraffin oil). Ogink et al. (2012) stated that water spray on the litter surface can reduce air particle emissions by up to 64%.

This is done to prevent dust from becoming airborne, especially in areas that frequently experience chicken movement or other activities that can generate dust. Oil spraying is carried out to stick dust particles to surfaces, thereby reducing the amount of dust flying into the air. The oil forms a thin layer on the surface that binds the dust.

Oil and water spraying can be done through a sprinkle or using a disinfectant sprayer. The type of oil needs to be considered because it can cause rancidity, especially if it gets into the feed. Therefore, in the field, mineral oil that does not easily become rancid is usually used, and it is sprayed carefully onto dusty spots. When spraying, do so when there is still a slight breeze and avoid times of high humidity, usually at night and in the morning. The spray should be done with very fine water particles or in the form of a mist.

3. Ventilation Adjustment

When humidity is too low/dry (<40%), the cooling pad can be operated so that the humidity will increase and be able to suppress the air particles inside the house. The cooling pad's operating time is based on the total even wetting of the cooling pad (on-time) and how long it takes for the cooling pad to start drying (off-time).

The adjustment of the inlet curtain opening must also be appropriate for the number of fans operating. Patterson PH (2014) stated that operational errors in the closed house system, such as an unbalanced ratio between the operating fans and the open inlet area, will lead to high dust levels in that house. As a result, the dust released from the house will be high and can contaminate the surrounding environment. The target air speed inside the house is around $2.0 – 2.5 \text{ m/s}$, and this target must be achieved to expel air particles and ammonia inside the house.

4. Filtration

Filtration is one of the most widely applied methods for removing particles from the airflow. Filtration usually occurs through a dry method (without adding water). Filters are generally used to remove dust particles from the farm. One type of filter is a biofilter. Biofilters are commonly designed to control ammonia and dust, helping to convert pollutants into inactive (inert) forms. Biofilters can use plant cuttings, bark, activated carbon, compost, or soil as organic filter media.

Filtration can be applied in the house by using a paranet/shade net installed in the air intake area (inlet) with a not-too-dense darkness level. The effective darkness level of the shade net is around $40 – 50\%$ so as not to obstruct the air circulation entering the house. This shade net is effective for trapping dust from the external environment and also functions slightly to trap air humidity entering the house.

5. Electrostatic Ionization

The Electrostatic Space Charge System (ESCS) is used to reduce dust and other airborne pollutants based on the basic principle of electrostatic charge. ESCS works by generating an electrical charge in the air in the form of charged particles (ions). Dust particles in the air will be attracted by the charged particles so that the dust particles can settle on the surface of the equipment (on the floor, walls, roof) and no longer circulate in the air.

6. Waste Management

Feces management is very important to reduce dust, maintain chicken health, and improve air quality. The running frequency of the manure belt/scraper must be considered to avoid the accumulation of feces. The manure belt is operated once a day, while the scraper is operated twice a day.

Other waste such as leftover feed, feathers, and eggshells must be collected in one place and then removed from the house every day. The more waste accumulates inside the house, the higher the potential for increased dust inside the house.

Thus, this is a brief overview related to the factors that influence air particle emission in the closed house layer cage and the appropriate control measures so as not to disrupt the layer chickens' performance. With proper control, the productivity of the layer chickens remains optimal, thus maximizing profits. Hopefully, this can add to all of our knowledge. Success always.