Question

Mrs. Sheila – By email

Please explain the correct application of chlorine on farms and the amount required for it to be effective in drinking water sanitation. Thank you.

Answer:

Thank you, Mrs. Sheila, for your question. Water is one of the essential needs for chickens. The availability of clean water throughout the rearing period is mandatory and significantly affects the health, welfare, and performance of the chickens we raise. One of the efforts we can make is disinfecting drinking water—one common method is chlorination (disinfection using chlorine-based chemicals). Chlorination during the poultry rearing period offers several advantages:

- Chlorine products are easy to obtain and affordable

- Simple to test and monitor

- Applicable through several methods

- Supports better animal health

Although chlorination is the most commonly used method for drinking water sanitation, other methods can also be applied—such as ozone, reverse osmosis, reverse osmosis, UV light, certain acidic chemicals, hydrogen peroxide, and others. These alternatives are used especially when chlorination is restricted for livestock drinking water in certain regions or countries.

Chlorine (Cl₂) is a chemical commonly used for disinfecting drinking water in poultry farms because it effectively kills bacteria, parasites, and other microorganisms. Chlorine is available in several forms:

Calcium hypochlorite (Ca(ClO)2)

Calcium hypochlorite also known as bleaching powder or HTH (High Test Hypochlorite). It can be found on the market in forms such as bleaching powder, HTH, and chlorine tablets. Bleaching powder is a mixture of calcium hydroxide, calcium chloride, and calcium hypoclorite. Containing 20–35% chlorine. HTH comes in powder, granule, or tablet form with 65–70% chlorine concentration. Chlorine tablets often contain additives to prevent powder formation, moisture absorption, and sometimes to aid dissolution.

Natrium hypochlorite (NaClO)

Natrium hypochlorite or known as household bleach with a chlorine concentration of 10-12% from natrium dichloroisocyanurate (NaDCC) in powder or granule form with a chlorine concentration of 56–60%.

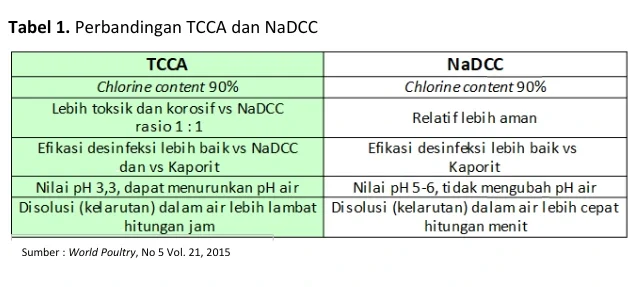

Trichloroisocyanuric acid (TCCA)

TCCA is available as white granules or tablets containing 90% chlorine. It is used as a disinfectant, algaecide, and bactericide—commonly applied in swimming pools, textile industries, and for disinfecting drinking water in livestock and aquaculture. TCCA dissolves more slowly than NaDCC.

TCCA chlorine in tablet form has been specially formulated to dissolve more slowly. Chlorine in this form is often used in pot chlorinator floating in the tank/torn water, or in some cases chlorine tablets in pipes or water channels. Chlorine reacts easily with other compounds, one of which is hydrogen (H). When chlorine is added to water (H2O), it forms ions. hypoclorite (OCl-) dan underchloride acid (HOCl). It should be noted that HOCl is more efficient and faster at killing microorganisms than OCl-. To maintain chlorine at HOCl concentration, it is necessary to maintain the pH of the water at around <8 (optimum pH 6.5–8). Chlorine can also be toxic when bound to other compounds due to its strong oxidizing properties. Therefore, water containing chlorine must be left to stand for at least 8 hours to allow the chlorine to break down and become safe for dissolving medicines or vitamins. Specifically, when administering vaccinations via drinking water, do not provide water containing chlorine or antiseptics for 48 hours before and 24 hours after vaccination, as the vaccine virus will be damaged and killed upon contact with chlorine.

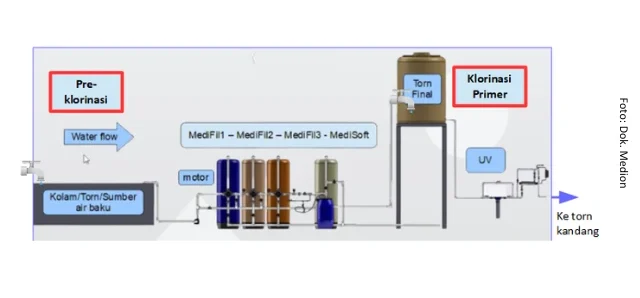

Chlorination can be carried out using three methods, namely pre-klorinasi, primary chlorination and secondary chlorination:

1. Pre-chlorination

Pre-chlorination is performed before water enters the Water Treatment Plant (WTP) usually for reasons other than disinfection—for example, to help reduce minerals such as iron (Fe) and manganese (Mn), or other substances that cause taste and odor changes (WHO, 2017).

2. Primary Chlorination

Primary chlorination is performed at the WTP. When using automatic dosing pump (Dosatron), chlorine tablets are recommended. Sodium natrium hypochlorite solution can be combined with organic acid to maintain optimal pH levels (below 8). The use of a Dosatron makes it easier to automatically mix natrium hypochlorite and organic acid (Hendrix Genetics, 2024). Primary chlorination can also be done by dissolving granular or tablet chlorine directly into torn the water storage tank or by letting water flow through a container filled with chlorine tablets (floating pot chlorinator).

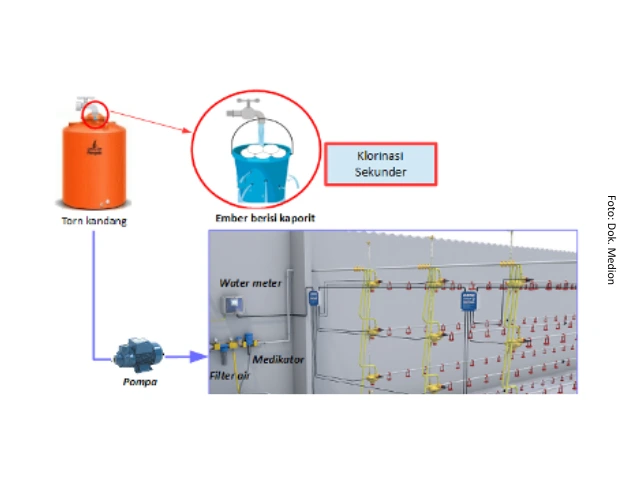

3. Secondary Chlorination

Secondary chlorination aims to maintain chlorine concentration levels. This chlorination is carried out at torn or water storage that will be distributed to the pens. Secondary chlorination is needed if the water travels from the water storage to the WTP (primary chlorination) too far.

The chlorination method commonly used on farms is manual. The manual (non-pump) chlorination method involves the use of chlorine granules or tablets. Chlorine Tablets can be included in pot chlorinator (bucket) floating in a tank or water tower, or in some cases chlorine tablets in the water channel.

We can determine the required chlorine level. monitor through measurement on free residual chlorine, which is at a level of 3–5 ppm measured from water samples taken at the end of the pipe/water channel. Measurement residual chlorine very easy to do. The chlorine level in the water is measured using a device. photometer which can measure the total and residual chlorine or using chlorine litmus tester.

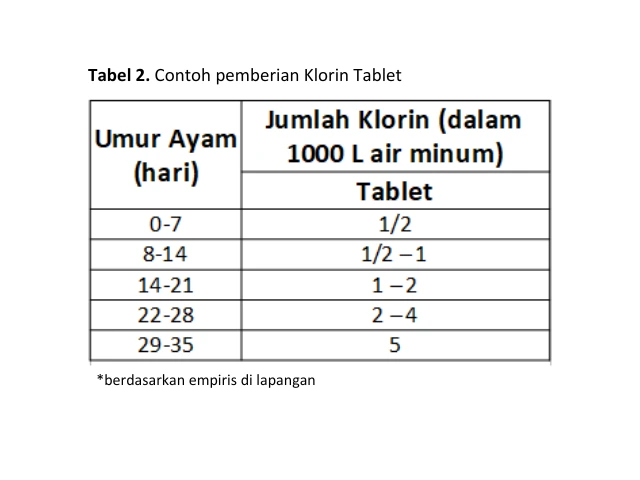

Number of Chlorine Tablets the amount added can be adjusted according to the age of the chickens and based on the estimated water consumption of the chickens or the total water requirement. Chlorine level as free residual chlorine most appropriate should be-monitor by taking measurements using a device. However, if the farm is not equipped with a chlorine level measuring device, the best way to ensure that the chlorine level is appropriate is to observe the palatability of the water and the drinking behavior of the chickens. Make sure that the chickens are still willing to drink from the drinking trough.

If the chlorine concentration is too high, chickens will tend to avoid drinking. If this happens, stop chlorination first by closing the water flow to the bucket/chlorinator pot. However, the water flow from the source or WTP continue running (do not skip the bucket/pot chlorinator). The goal is to reduce chlorine levels due to ongoing dilution. Flushing water can be used to replace highly chlorinated water with new drinking water, then re-chlorinate by reducing the amount Chlorine Tablets which is in the bucket/pot chlorinator before being fed back into the pipes or waterways. The amount used Chlorine Tablets may vary from farm to farm. The following are examples of feeding amounts Chlorine Tablets in the field.