Facing the era of Industrial Revolution 4.0, farms are required to be able to compete in terms of product quality and operational cost efficiency. Therefore, chicken farms now prefer to improve everything related to maintenance management.

In Indonesia with its tropical climate, maintenance with the system open house has many factors that can not be controlled. When the weather is hot, the chicken will do. “panting” as a defense effort. At the same time with high air temperature and humidity make chickens have difficulty removing body heat. Weather forecast (global warming) as well as genetic changes in chickens broiler, challenges of disease, disturbance of wild animals and environmental complaints against odors and flies also affect the efficiency of maintenance.

This means that it is very important for us to pay attention to the comfort of the chicken. Because by meeting the needs of chickens, it is expected to produce good performance as well. With the help of technology closed house we can achieve that comfort. Some breeders have proven that by using closed house able to improve livestock performance and have better competitiveness.

System closed house it is a cage system that can remove excess heat, water vapor, and harmful gases (CO, CO₂, Nh₂) in the cage but on the other hand can provide oxygen (O₂) for chickens so that the performance of chickens remains optimal (Poultry Indonesia, 2011). The development of farmers who use closed house, good full closed house or semi closed house more and more every day.

System Advantages Closed House

Advantages of keeping chickens with the system closed house among them are:

- Increased density

Cage density open house range 13-15 kg / m2 and when using closed house the density of the cage will increase by almost 2x, reaching 25-30 kg / m2. This of course will minimize the need for land that is currently increasingly difficult and expensive to find. Moreover, there have been many cases of closure of cages because they are adjacent to residential areas. This increase in capacity is further increased when the cage is made multilevel, both two and three levels.

- Controlled environment

Chickens kept in cages closed house it becomes more comfortable because the temperature in the cage is more stable and can be adjusted as needed. In addition, O₂ needs are more fulfilled, the air in the cage is cooler and fresher because of good air circulation. This will affect the quality of the dirt removed. The feces become drier. Moreover, the existence of exhaust fan more or less will help improve the quality of feces. The presence of flies can be further suppressed.

- Low mortality

The comfort provided by the cage closed house making chickens have a good immune system so that they can fight the challenges of disease and produce good performance.

- Efficiency of Human Resources (HR)

Automatic system applied to the cage closed house make the required HR more efficient. However, it should be noted that although the system closed house very supportive of the success of the business, it becomes meaningless if not accompanied by good management. Absolute Cage Power mastering technical production and technical tools.

With the use of enclosures closed house, HR must really be trained on an ongoing basis in order to be competent. Because, most of the power cage originally use traditional equipment such as in open house so that when using modern equipment such as closed house usually a lot of problems that often occur in the field.

- Biosecurity controlled

Implementation and effects biosecurity can be controlled, wild animals from outside the cage is minimal and disease transmission can be suppressed.

- Optimal performance

Improved chicken performance is the main advantage of the system closed house. This is what often makes farmers change their minds. Chicken productivity is increasingly difficult to achieve optimal, making farmers look for solutions. And one of them is to make the cage as comfortable as possible for the chickens. It is hoped that when the condition of the chicken cage is comfortable, the body will be able to optimally. Performance Index (IP) of chicken broiler when using cages open house range 260-370 while when the cage is converted into closed house can increase to 400-420 (Trobos, 2018). The higher the achievement of IP then the farmer's profit will be greater. In other words, chicken performance increases with better feed efficiency.

Critical points and completeness of the system Closed House

Critical points in the system closed house is a ventilation system. Proper calculation and arrangement of the ventilation system can create a temperature and air quality in accordance with the needs and a balanced wind speed so that the condition of the chicken becomes comfortable.

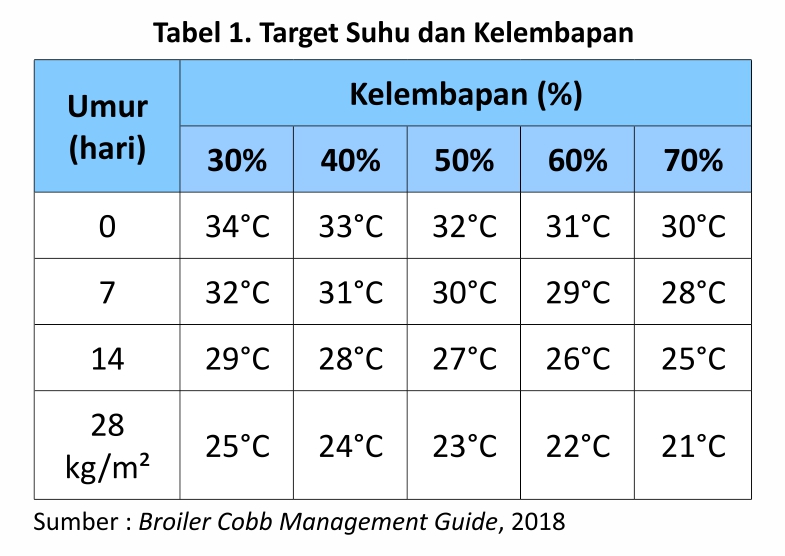

The following is the target temperature and humidity of the cage to stay in the comfort zone of chickens (Table 1).

Completeness of the ventilation system closed house consists of exhaust fan, evaporative cooling pad, controller and the cage curtain.

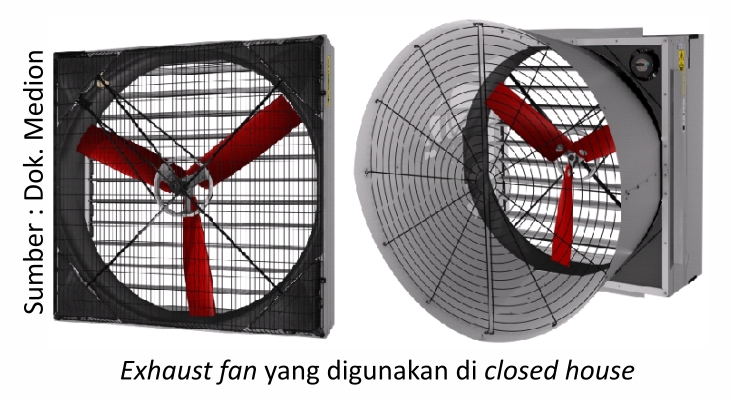

- Exhaust fan

Fan (fan) is a device that creates air movement. In general, there are 2 types of fans, namely exhaust fan and blowing fan.

Exhaust fan serves to suck the wind and blowing fan serves to blow the wind. Thrust blowing fan very limited, ie a maximum of 12 meters by blowing fan 36 inch capacity of 20,700 m3/h at a pressure of 50 Pa. System closed house generally use exhaust fan.

The parameters that need to be considered in operating the fan are the number, capacity/size and length of time the fan is on and the position of the fan is on. Selection of the right fan is necessary in order to produce air speed and temperature in accordance with the optimal electrical power consumption.

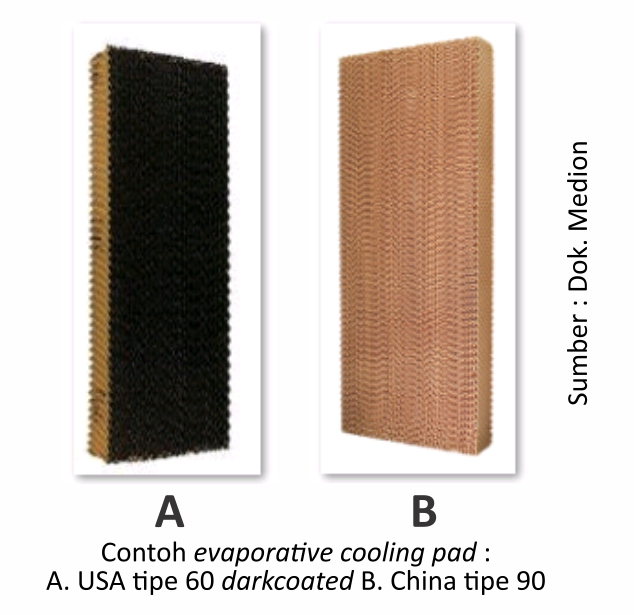

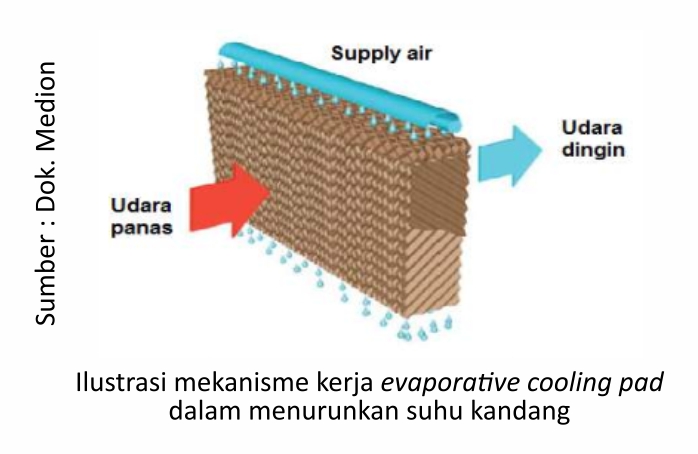

- Evaporative cooling pad

Evaporative cooling pad is an air conditioning device that utilizes the evaporation of water. Evaporative cooling pad connected to a pump that will wet it with water. When hot air from outside the cage enters cooling pad, the water will take heat energy from the air so that the water will evaporate (evaporation process) and result in a decrease in the temperature of the air entering the cage. Breeders are not recommended wetting cooling pad when humidity >85%, because it will increase the humidity of the cage.

Evaporative cooling pad also serves as a filter for air entering the cage. Block-block cooling pad prevent air impurities (large) to enter the cage, so that the incoming air becomes cleaner.

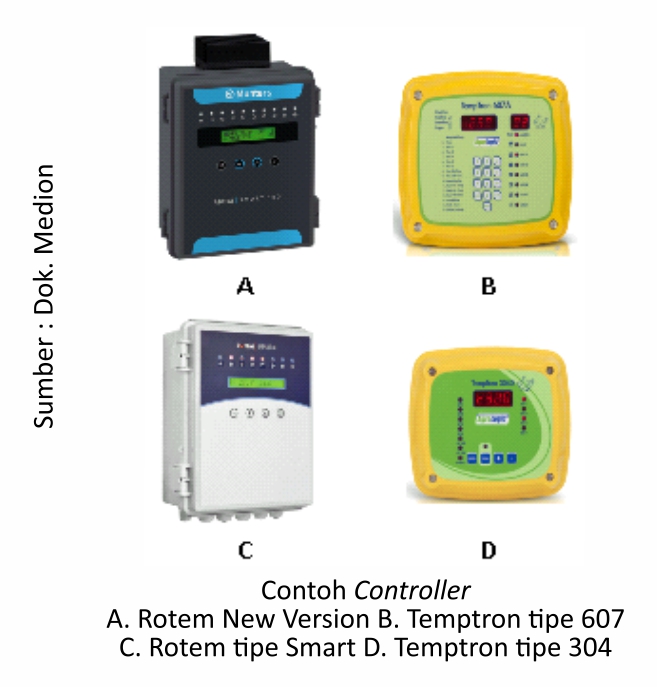

- Controller

Controller atau climate controller is a device for controlling the temperature and humidity in the enclosure. In addition, it can also be connected with heater, feeder, waterer as well as curtains (according to type and brand). This tool is often referred to as his “brain” closed house. Controller it can be programmed in such a way with the target of making the atmosphere of the cage, namely the temperature and humidity comfortable for chickens. Controller will set the fan on or off (exhaust fan) and the pump on evaporative cooling pad.

- Curtain cage

The cage curtain is the side cover of the cage so that the chickens are protected from outside interference. In addition, on the system closed house cage curtains are also useful for :

- Generate the required static pressure in the system closed house

- Provide emergency ventilation in case of power failure (Dead fan)

Cage curtains combined with the system winch (pulley), to make it easy to raise or lower the curtain quickly, just one operator. In addition, the curtain can also be connected with controller it will open automatically when needed (automatic curtain drop).

Temperature regulation mechanism on Closed House

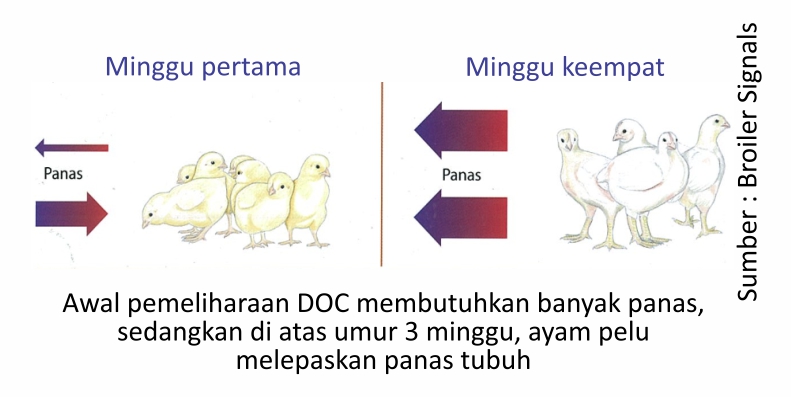

Symptoms over heating often occurs at the age of 21 days and over, when the chicken's body broiler it's getting bigger and producing its own heat. Different ages of chickens require different temperatures and tolerances to different wind speeds (eg DOC = still air, 1 Week = 0.5-1 meter/SEC).

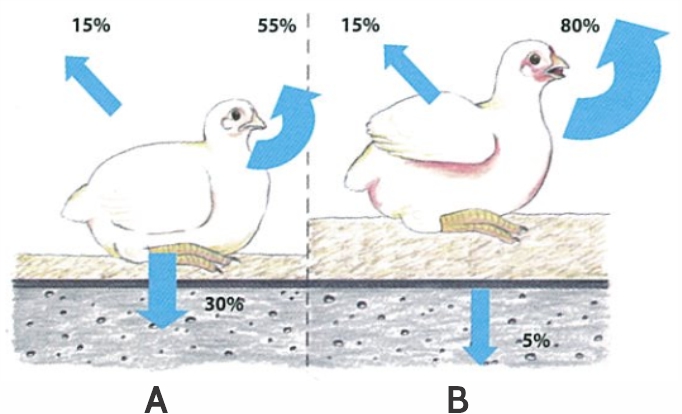

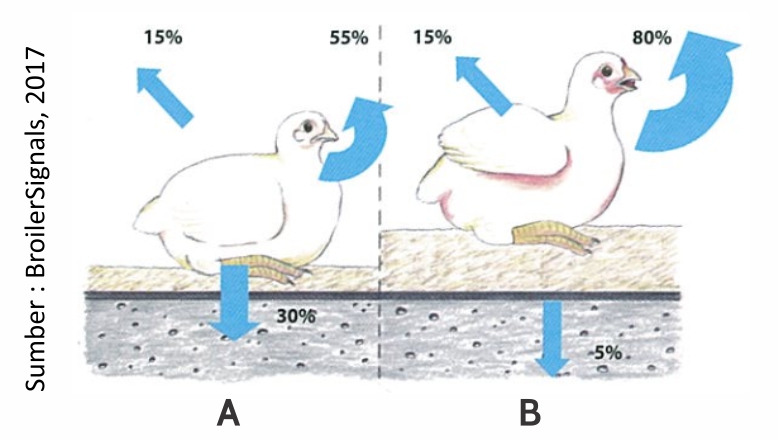

The temperature detected on the thermometer is often confused with the temperature felt by the chicken's body. Though it is not so. The temperature felt by the chicken's body is called the effective temperature. And this effective temperature is influenced by 3 factors, namely room temperature (the temperature detected in the sensor), humidity and the speed of air flow in the cage (which hits the chicken's body.

Air humidity (relative humidity or RH) is the level of water vapor contained in the air. Humid air (containing a lot of water vapor) will inhibit the rate of evaporation from the chicken's body, so that the temperature felt by the chicken will be higher than room temperature (thermometer temperature).

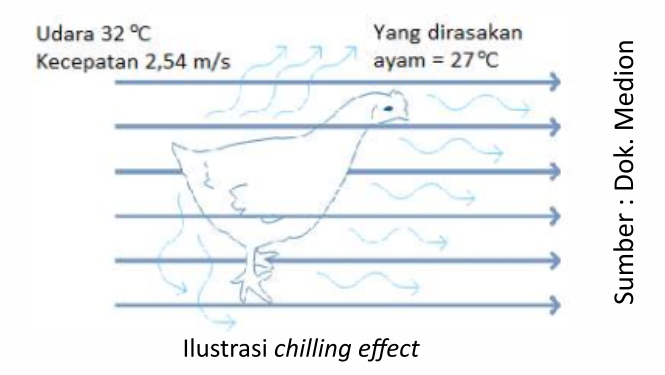

And although the room temperature is high, but if there is air flow, the temperature felt by the chicken's body will be lower. This is what is called chilling effect.

Chilling effect is the effect of a decrease in temperature felt by chickens due to the speed of the wind that blows. The tool that plays a role in this effect is the fan. The higher the wind speed, the chilling effect perceived greater or lower effective temperature. It's just that the wind speed that hits the chicken's body needs to be taken into account. For chicken broiler the recommended wind speed is 0.3 m / sec at the time of brooding period, and 3 m / sec when age >28 days.

When dry environmental conditions, where low air humidity (low RH) ignition evaporative colling pad will help lower the air temperature in the cage and the temperature felt by the chicken's body. Decrease in air temperature by utilizing the process of evaporation of water is called cooling effect.

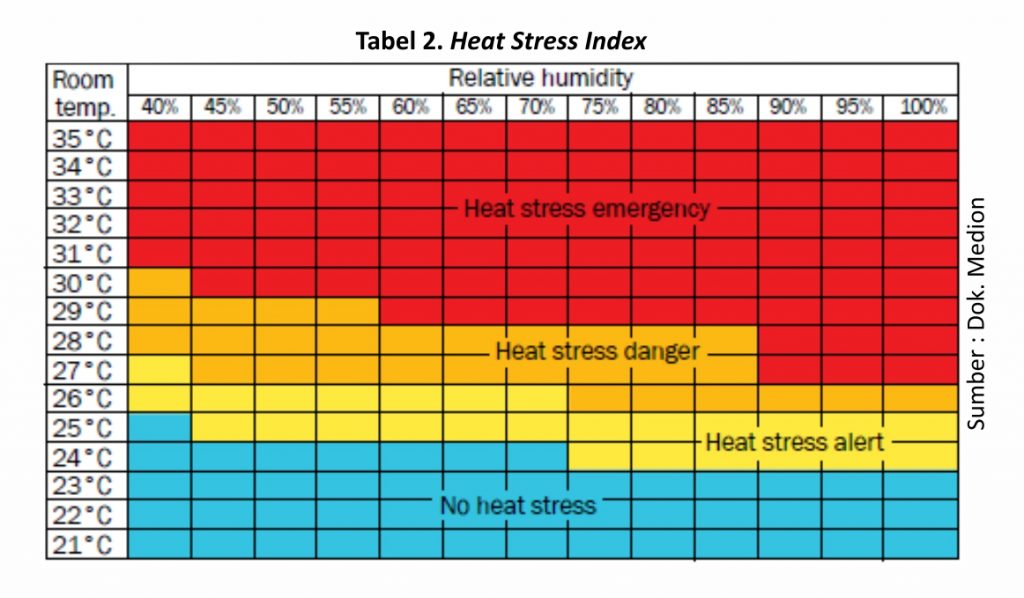

Heat stress index is a parameter that can help us to see the comfort of the air in the cage. This index is a correlation between the temperature and humidity of the enclosure. Safe limits heat stress index for chicken broiler it was 85-95. Formula heat stress index is the sum between temperature (°C) and humidity (%). Table 2 shows heat stress index.

Chart 2. Heat Stress Index

Wind speed in the cage is influenced by many factors including :

- Fans : Number, capacity, tightness belt, hygiene blade, motor power that decreases with age, and uniformity between fans.

- Cage density: check for perforated side curtains or other holes (ceilings, building connections) in the cage that cause air to enter through the hole, not through inlet (cooling pad) on the front of the cage.

- Luas cooling pad

The nonconformity of the three things above can cause turbulence so that the air flow and wind speed in the cage are not optimal. Airflow velocity in the enclosure closed house can be measured , conducted via windmeter.

The maximum wind speed in the cage is 3 meters / SEC. The higher the wind speed, the greater the effect of lowering the temperature felt by the chicken's body. The negative impact of high wind speed is to fly the dust from the base of the cage which triggers breathing disorders due to dirty air coming from dust. In addition, the perceived effective temperature of chickens that is too low will result in reduced consumption of chicken feed. This condition can cause feed intake not achieved. The wind speed is also affected by the cage curtain.

Signs Of Ventilation Problems

Uneven airflow in the cage leads to disruption of the growth and performance of chickens. Therefore, observe the behavior of chickens and around the cage to determine ventilation problems that occur:

- Chickens collect in the middle of the barn

Chickens gather in the middle of the cage or as if avoiding the edges / sides of the cage. This is due to too slow wind speed. Generally, the condition of the wind speed is too slow found on the left and right sides of the cage, causing the temperature on the left and right of the cage to be hotter than in the middle of the cage. Therefore, chickens will tend to avoid these hot areas (also called Regions dead spot).

This problem can be solved by minimizing the gap in the curtain opening inlet cooling pad or modify the roof where the roof is given a ceiling. With the installation of the ceiling causing hot air to gather in the area of minimal wind flow can be avoided.

2. Chickens gather on the left and right sides of the cage and tend not to move or sleep much

This sign is caused by wind speeds that are too fast or strong and have an impact wind chill effect a big one, so that the chicken gets cold. Cold chickens will reduce activity so that the energy from the feed is not wasted for movement activities, and is used to heat the body. Thus will have an impact on reducing feed intake and slowing growth broiler. This can be solved by widening the gap in the curtain opening inlet cooling pad or turn off some fans that are on. Ensure that the effective temperature required by the chicken is reached.

3. The spread of chickens is uneven

An uneven spread of chickens indicates an uneven temperature of the cage. Uneven cage temperature can be caused by air holes. Holes in the curtain or ceiling enclosure closed house it's a big deal.

The airflow is also said to be problematic if :

- Causing many areas with minimal airflow (”dead areas").

- Hot and humid air will be in the area inlet, outlet, and the sides of the cage.

- The working power of the fan is getting heavier because it has to draw air from the leak hole.

Locations that need to be considered because of the frequent leakage of air holes are:

- Cage curtain connection.

- Upper floor trusses (air outlet from second floor to first floor).

4. Wet/damp husks

A wet or damp husk indicates a too slow wind speed. During the production period, a lot of gas and water vapor is produced. 80% of water consumed by chickens broiler will be excreted into moisture that must be removed from the cage. Water vapor that is not wasted through ventilation will be absorbed by the husk and cause wet husk.

5. Pungent smell

One of the common problems that arise in chicken farms is the problem of ammonia odor. Ammonia Gas has a high irritating power, especially on the mucous membranes in the eyes and respiratory tract of chickens. When we enter the cage and the smell of ammonia is smelled, it means that ammonia levels are above the threshold (>20 ppm). Beyond this safe threshold, ammonia will cause harm to chickens, both in the form of damage to the eye and respiratory membranes.

The causes of increased ammonia levels include:

- Obstructed air circulation system .

- The density of the cage is too high.

- Management litter less than optimal.

- Feces released by chickens are wet or diarrhea.

Therefore, some measures to prevent increased ammonia levels are to:

- Regulation of air circulation.

- Set the appropriate cage density.

- Management litter the good (do pembolakbalikan litter regularly every 3-4 days and pay attention to leaks from chicken drinking places).

- Check and correct the nutritional quality of the ration (so that the feces do not get wet).

Usage closed house in the chicken business broiler does require higher capital at the beginning of construction, but if we know the critical point of the system closed house, so many advantages that we can feel. Greetings.