The problem of ammonia odor on chicken farms is known to be quite detrimental in poultry farming. This cannot be underestimated because it can interfere with the comfort of chickens to cause various health problems, especially respiratory disorders. In addition, ammonia is a source of air pollution to the environment around the cage.

Ammonia in the chicken coop

Ammonia (Nh₂) is a gaseous form produced from the process of breaking down nitrogen residues by decomposing bacteria (ureolytic bacteria) derived from chicken droppings or feces. The production of ammonia itself cannot be avoided. Why?

One of the constituents of chicken rations is that protein will be digested and metabolized to produce waste substances in the form of urea and uric acid which are discarded along with feces. Both urea and uric acid, both contain nitrogen elements (N) which will be converted into ammonia (gaseous Nh₂) or ammonium (NH₄₊ dissolved in feces) by decomposing bacteria (ureolytic bacteria) in the environment. Therefore, it is natural that in the maintenance of chicken livestock ammonia is produced. The formation of Nh₂ is influenced by several factors including :

- The presence of high humidity and relatively low temperatures will make the urea content containing nitrogen eventually decompose into ammonia and CO₂ gas.

- In general, the pH in feces and litter ranges from 7.5 to 8.5. pH litter >7 dapat meningkatkan produksi amonia, produksi amonia dapat ditekan pada pH <7, karena amonia (NH₃) akan dikonversi menjadi amonium (NH₄₊).

- The density of chickens also affects the high ammonia in the cage. The high density of chickens causes higher cage pressure and air circulation does not work well.

- The higher the protein content in the feed, the more it increases the likelihood of ammonia odor from chicken feces.

- The postal cage, litter damp and wet ones can increase the ammonia content and become a breeding ground for various breeding agents.

- Pada kandang panggung, tumpukan feses di bawah kolong kandang yang terlalu banyak atau feses basah bisa menimbulkan bau amonia yang mengganggu. Kondisi ini akan lebih parah jika ketinggian kolong kandang tidak sesuai (<1,5 meter) sehingga feses tidak cepat kering. Feses yang jatuh ke bawah mengeluarkan bau amonia yang dapat naik ke atas kandang apabila tidak mendapat sirkulasi udara dengan baik.

Impact Of Ammonia

To detect ammonia levels in the cage can be by using an ammonia indicator device, namely an ammonia meter. Place it at the right height, for example 10 cm from the floor or equivalent to the height of the chicken's head. In addition, the easiest way to find out the smell of ammonia, if we enter the cage and the smell of feces has begun to sting, then the ammonia level can be said to be excessive.

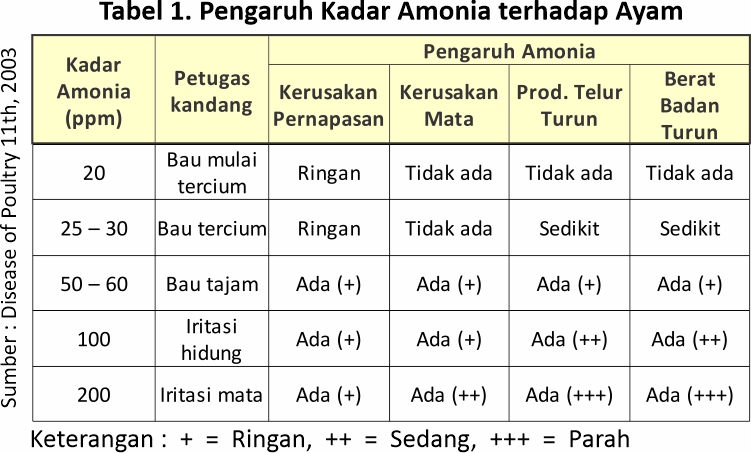

Ammonia gas content in the cage has a certain tolerance limit for chickens that can reduce productivity. Cage attendants can smell ammonia at about 20 ppm. The maximum level of ammonia that can be tolerated for 8 hours is 25 ppm. Ammonia concentrations reaching 20-25 ppm can actually trigger respiratory diseases in chickens. Ammonia production of more than 25 ppm can also cause livestock to experience oxidative stress so that it can affect the quality of meat (Xing et al., 2016). The tolerance limits for Nh₂ levels in broiler chickens are presented in Table 1.

At high levels, ammonia can have a negative impact on the performance and immune system of chickens. Here are some of them:

- Impact on the eye mucosa Ammonia will dissolve in the eye fluid and produce ammonium hydroxide (NH4OH), which are components of alkaline compounds capable of irritating and causing conjunctivitis (inflammation of the conjunctiva of the eye).

- Impact on the respiratory tract If the ammonia level has reached >20 ppm, ammonia will cause ciliostasis (cessation of cilia movement) and desiliosis (Cilia damage) in the mucous membrane of the respiratory tract. As a result, ammonia with high levels can indirectly trigger cases of respiratory tract infections such as CRD, korisa, ND, AI, IB and ILT.

- Impact on the breeding of disease seedlings Condition litter dampness causes ammonia levels to increase. Along with the process of converting residual nitrogen into ammonia, CO₂ gas is also produced. High CO₂ levels in cages cause anaerobic conditions so that bacteria Clostridium quickly multiply. If the bacteria contaminate the ration and are eaten by chickens in large quantities, then the infection Necrotic Enteritis (N) it can happen.

- Impact on the immune system In addition to damaging the cilia, ammonia can also damage the epithelial cells of the upper respiratory tract so that the production of mucosal immunity (IgA) will decrease. Ammonia whose levels are very high can also enter the bloodstream (due to being sucked in large quantities) and cause stress on lymphocyte cells so that the production of antibodies (IgG and IgM) is disrupted.

- Impact on the reproductive tract Ammonia Gas with levels > 30 ppm can cause alkalosis conditions (pH of body fluids, including blood plasma fluids are alkaline) in chickens. If the blood plasma is alkaline, then most of the plasma proteins will bind to blood calcium ions (which were previously free ions that will be stored in bone tissue and oviducts)oviduct)). As a result, the formation of bone/skeleton of the chicken body was disrupted and the resulting egg shells become thinner.

Control and minimize ammonia

What steps should be taken if ammonia has a pungent smell in the cage?

- Temperature and humidity control

- In areas of tropical hot climate reduction of air temperature in the chicken coop can be done with the help of blower or a fan in the cage. In the installation, blower should pay attention to the direction of wind flow (wind direction should not be back and forth/irregular), chicken population, wind speed and volume of the cage room.

- Pay attention to the air vents in one cage, arrange so that the incoming air is not too much and not too little.

- Air arrangement of the cage closed house the most important thing is to strive for air quality uniformly and evenly throughout the cage.

- Management litter and feces

- Make sure litter dry, then it will make the chicken comfortable. Litter we hold it for a while and when released it is still spreading (not clumping) this means litter still in good condition.

- Choose material litter quality (dry, not dusty, able to absorb water optimally) as well as in sufficient quantities (not too thin). Use litter with optimal thickness, which is 8-12 cm for postal cages and 6-8 cm for stage cages. Perform flip-flops litter regularly every 3-4 days, from the age of 4 days to the age of 17 days. This is to avoid litter lumpy from the start.

- If litter wet and lumpy in a small amount, immediately take out and replace with a new one. It should be sprinkled with lime in advance so that it dries quickly, after which it is simply stacked with litter the new one. However, if litter which clumps a lot, it is better to add litter new. Do not forget litter previously used substitutes are sprayed using disinfectants such as Medisep or Zaldes.

- Cage comfort

- Adjust the density of the cage and air circulation in the cage. Do not forget to add a curtain opening for air circulation in the cage (open house) cooler.

- In the stage Cage, the distance between the floor cage and the ground in the stage cage ranges from 1.5-2 meters to provide air circulation to the feces that fall so that they dry quickly and do not cause annoying odors.

- Be careful when replacing or filling the drinker. Do not Spill Drinking Water. In addition, pay attention to the condition of the drinking place or paralon and immediately repair the leaking critical condition.

- Minimise ammonia

- Provide a feed ration with balanced nutrient composition, particularly with appropriate levels of crude protein and salt. Diets containing excessive crude protein or salt may increase water intake in chickens, resulting in watery (wet) feces that create favorable conditions for fly breeding.

- Use materials that are able to work to bind ammonia, namely Ammotrol. Ammotrol can be used to make the stool texture drier and reduce the smell of ammonia in the cage

- It is not uncommon for the smell of ammonia to trigger the arrival of flies in the cage. To combat the presence of flies can be added Larvatox at a dose of 100 g per 1 ton of ration.

Good air quality can be created if we reduce the concentration of ammonia gas that can trigger a decrease in quality. Hopefully this supplement discussion can provide useful information for you. Greetings success always!