Chicken performance development broiler modern very rapidly along with the development of technology and climate change. Broiler Management modern has the characteristics of growing very fast, requires balanced feed nutrition, requires good maintenance management, produces higher body heat, requires adequate cage ventilation. Cages that are able to meet the comfort of chickens is a cage system closed house with the condition of the air can not enter unless it enters through inlet and get out through outlet made in a ventilation system. The system is able to remove excess heat, water vapor, and harmful gases (CO, CO₂, Nh₂) in the cage, and is able to provide O₂ needs for chickens so that optimal chicken performance (Poultry Indonesia, 2011).

Advantages Of Enclosures Closed House

Advantages of enclosures closed house include:

- Minimize the influence of environmental conditions outside the cage

- Increase the productivity and performance of chickens broiler

- Controlling temperature, humidity and air speed

- Minimize the impact of environmental pollution (odor and flies)

- Biosecurity more awake

- Health is more assured

- Land efficiency for enclosures

- Labor efficiency

Cage closed house able to provide proper ventilation in accordance with the needs of chickens, where proper ventilation should be able to :

- Maintain air exchange in the barn

- Controlling air humidity

- Ensure the air quality and oxygen needs of chickens

- Removing harmful air content (ammonia)

- Maintain air pressure in the enclosure

- Produce effective temperature for chicken

- Improve production efficiency

Parts of such ventilation systems are :

- Control climate : Ventilation system work regulator

- Inlet : Cooling pad (cell pad, rain maker, water pump), inner area inlet/dog house area, curtain inlet, tunnel door.

- Outlet : Fan (motor drive, propeller, van belt, pully), shutter, cone.

- Heating system : Heating (spot heater, space heater)

- Curtain system : Cage side curtain

- Curtain blocking : Curtains in the cage (period brooding period,).

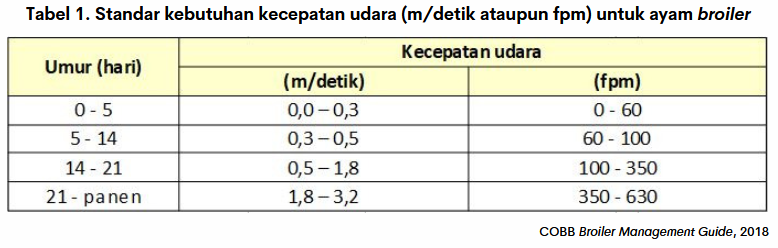

To calculate the need for a fan in the enclosure closed house we must know what is the target air velocity in the cage from the beginning of maintenance to the end of maintenance. The speed at the beginning of rearing is about 0.3-0.5 m/sec, while the maximum air speed at the end of rearing for adult chickens is about 3.0-3.2 m/sec. The formula for calculating the number of fans, it must be known, among others :

Cross section area or the cross-sectional area of the cage

= Cage Width x cage height

Maximum air capacity

= Cross section area x maximum airspeed

= 27 m² x 3,2 m/detik x (3.600 detik)

= 311.040 m3/h

Total number of fans

= Maximum air capacity : fan capacity

= 311.040 m³/jam : 42.000 m³/jam

= 7.4 fans or 8 fans

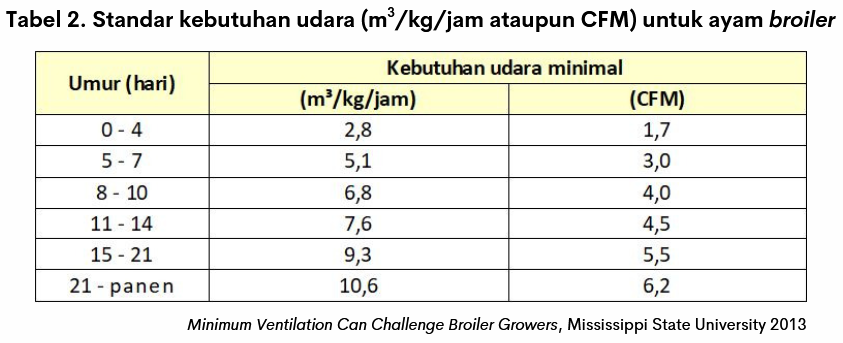

From Table 1, we can determine the target airspeed in the cage closed house during each maintenance period. From Table 2 we can calculate how many fans on/ necessary so that the comfort conditions of the chicken is maintained.

Ventilation system inside the cage closed house is the main thing we need to pay attention to. The ventilation system will regulate the process of replacing the air in the cage with fresh air from the outside as needed to meet oxygen demand, the process of removing toxic gases, the process of regulating temperature and humidity, and creating an effective temperature according to the needs of chickens.

Ventilation system in the cage closed house there are several such kinds of cross ventilation systems, longitudinal, tunnelroof, roof, roof combination and tunnel, as well as a combination longitudinal and tunnel. Generally cage ventilation system closed house existing in Indonesia is the ventilation system tunnel.

In the ventilation system tunnel or the tunnel is divided into 3 stages according to the age of the chicken, namely minimum ventilation, transition ventilation, and maximum ventilation. The ventilation stage is a critical point of the application of ventilation in the cage closed house. The application of such ventilation must be adapted to the age of maintenance and environmental conditions in the cage.

- Minimum ventilation

Minimum ventilation is the first stage of the ventilation system closed house where the amount of air exchange is determined by the timing or timer from control climateit is not regulated by temperature.

Time on and off from the fan intermittent the required during the minimum ventilation period should be calculated. This period is programmed into the timer in five-minute cycles, and the settings of this program are independent of temperature or heat settings. The goal is to remove moisture and improve air quality for chickens. Fan time on it is ideal for setting the start is not less than 30 seconds from five minutes. As the age of the chicken, water consumption, housing conditions and air quality then time on inside the minimum ventilation cycle should also increase. Time addition on the fan should correlate with an increase in water consumption inside the enclosure. In determining the cycle on-off we must know the standard air requirements in units of cfm or m3/kg/hour. The formula for calculating the minimum air requirement in the cage is the total CFM/tail requirement multiplied by body weight (kg) multiplied by the number of chickens in the cage (tail).

2. Transition ventilation

Transition ventilation is applied when the target temperature inside the cage with the temperature outside the cage is relatively the same and has not been too hot. At this stage of ventilation cooling process in the cage rely only with a little addition of air velocity above the minimum ventilation (0.5-1.8 m/sec).

This ventilation is in principle only the transition of the stages of ventilation, namely from the minimum ventilation stage to the maximum ventilation stage and has not required a cooling effect with cooling pad.

3. Maximum ventilation

Maximum ventilation is required when chickens broiler entering the period finisher when the temperature in the cage above the desired target (22°C-25°C), then the required effect of high air velocity to cool the temperature in the cage (wind chill effect). Maximum ventilation is applied when the temperature inside the cage is warm to hot by activating cooling pad.

In the process of maximum ventilation this high air velocity combined with the effect of the use of cooling pad to achieve the comfort of chickens. Maximum ventilation is important to use especially during the summer in the tropics. For tropical areas because the outside temperature is sometimes relatively higher, the application of maximum ventilation can be applied at the end of the period starter until finisher.

Maximum ventilation system most of the airflow is tried to move at the level of the height of the chicken and hit the chicken's body with an air velocity of 3.0-3.2 m/sec and evenly distributed in all areas of the cage.

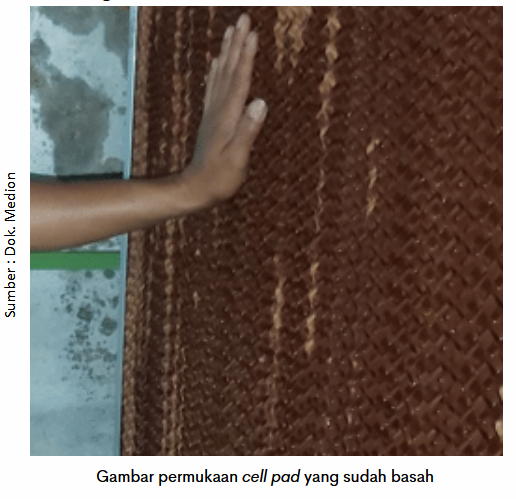

Maximum ventilation is operated by adjusting the number of fans on based on the temperature read in the cage. As for the initial settings for use cooling pad will be based by a combination of minimum standards of airspeed, temperature reached, but limited by the humidity it generates. Time on-off from the use of cooling pad this is set based on how long it takes to wet the entire surface cell pad and how long does it take to cell pad began to dry.

When this maximum ventilation mode is operating, the heating system is good spot heater/IGM or space heater/Super Saver 225 already it does not work because what is needed is the cooling effect of the ventilation system. If the temperature in the enclosure rises above the target, then the fan works continuously based on the temperature control and until it needs setting cooling pad as per minimum airspeed standard to start using cooling pad.

In the application of the ventilation stage there are several parameters that must be considered because it greatly affects the accuracy of the ventilation system, among others :

- Static pressure (air pressure in the cage) about 0.1 inch of water or 25 Pa, the pressure aims to get a good air flow, namely cold air that enters mixed with warm air in the cage at the ceiling position or at a level above the chicken (not directly to the area litter), so as not to cause condensation in the bottom area that can make litter get wet quickly.

- Inlet, aperture area inlet this aims to get the right air pressure so that the air flow is also right, then the width inlet it should be just right (not too wide and not too narrow). Aperture width inlet is adjusted to the number of fans on.

- Setting control climate, setting setting ventilation (fan and cooling pad) on control climate to be precise is when to start start on and offso that it will be able to carry all the incoming air to the entire area in the cage.

- Timer, cycle setting on-off in the minimum ventilation should also correspond to the weight and age of chickens, and the function of this cycle to maintain air quality.

If any of the four criteria are not appropriate or less precise, it will have an impact on the conditions in the cage, for example litter wet, high ammonia, wasteful fuel gas, and poor or not optimal performance.

Determination Of Aperture Area Inlet

Inlet it is made in the area cooling pad and used in setting the extent of the area where the air enters based on the number of fans on. Size of aperture inlet this will affect the amount of air entering due to the opening inlet this is the entrance of air into the inner area of the cage.

If the area inlet open too wide then the incoming air flow from cooling pad will fall down/area litter causes litter it is easy to get wet and dry, and vice versa inlet too small it will result in air velocity will be higher in certain areas and an increase in negative pressure in the cage. Determination of aperture area inlet this is based on the number of fans on and target the desired airspeed.

Examples of calculation of inlet area openings :

Fan capacity = 42,000 m3/h

In units of seconds = 11.66 m3/second

Target airspeed at cell pad (type 45°/45°) = 2.0 m / sec.

Total area length cooling pad (right and left side) is 30 m.

Then the area inlet include

= Fan capacity : target air speed

= 42.000 (m³/jam) : 2,0 (m/dtk) : 3.600 (dtk)

= 5.83 m2

Opening area inlet include

= Area inlet : total length cooling pad

= 5.83 m2: 30 m

= 0.19 m or 19 cm

Trouble Shooting Ventilasi Closed House

Problems that often arise in the cage closed house due to improper ventilation settings, among others :

- Off the wind/blank spot and low airspeed

Blank spot is the condition in a certain area in the cage that the air speed drops dramatically or even to 0 (no air speed). This is caused by changes in air pressure or from the influence blocking ventilation.

The negative pressure inside the enclosure will be higher if the air velocity generated by the fan is high enough while inlet relatively less. The positive pressure will be higher if the air speed generated by the fan is slow while inlet relatively large.

Static air pressure/static pressure its unit is the inch of water or pascal (Pa). Air pressure gauge can use Magnehelic Static Pressure Meter and Floating ball Static Pressure Meter. In a good Cage ventilation system the pressure is about 0.05-0.10 inches of water or about 12-25 Pa.

Solutions to reduce blank spot among others:

- Adjust between inlet and outlet (balanced)

- Avoid area inlet and cell pad from obstacles / blockages. Inlet reduced due to the presence of curtains cooling pad the walls are too thin, the walls are too thin, and cell pad the dirty one.

- Avoid leakage enclosure (curtain and ceiling)

- Additions spoiler/baffle

- Determination to determine how high spoiler/baffle are as follows :

Cross section area should be

= Total fan capacity : desired air speed

Then high spoiler is,

= Cross section area should be: cage width

Examples

Capacity 7 units = 294,000 m3/h

Target airspeed = 3.2 m / sec

Cage width = 12 m

Cross section area should

= 294.000 : 3,2 : 3.600

= 25.5 m2

Height spoiler

= 25.5 m2: 12 m

= 2.1 m

If it is too low then the pressure will get higher and reduce the volume of air. Distance between spoiler about 9-12 meters.

- Make sure the fan motor, van belt, and shutter in good condition.

2. Uneven airspeed distribution

To determine the distribution of air in the cage will be more visible by using a smoke test. This test will show the distribution of air distribution throughout the area in the cage. If in a certain area there is no flow of smoke, it can be said that the area has no air flow so it needs to be anticipated by :

- Clean the area inside the cage of objects or materials that block the flow of air (eg a pile of sacks, plastic or tarpaulin that blocks the flow of air.

- Additions tunnel door to create an even flow of air to the back.

3. Uneven cage temperature

The temperature in the cage is said to be uneven if the difference or difference in temperature between the front and back of the cage above 2°C. A warm-up when viewed with thermometer infrared then it will have the same color from the front to the back of the cage. And this happens if the distribution of chickens and the distribution of air are also evenly distributed in all parts.

4. High humidity

High humidity in the barn will result in litter wet and lumpy. Causes of litter the clumping can come from improper management of drinking water (leakage) and also from improper ventilation management, namely openings inlet that is too wide or the number of fans on the less. The action to be done is to check between the target air circulation with the actual speed generated, and the adjustment of the opening balance inlet by fan volume on.

The next solution is the use of cooling pad exactly. How evaporative cooling works by cooling pad is the hot air coming through cell pad will come into contact with water. The hot air will release energy (heat) to the water. As the air releases energy, it becomes colder. Water uses the energy provided by the air, to change the phase from liquid to vapor (evaporation). The cooling effect will largely depend on the amount of water vapor already present in the outside air of the enclosure (RH). The lower the humidity outside the cage, the more water vapor can be absorbed by cooling pad, so that the greater the potential decrease in temperature inside the cage and vice versa. Note that the ability of the temperature drop in the cage depends on the temperature and RH outside the cage, the type of cell pad, the degree of wet flatness of the surface cell pad.

The higher the humidity level of the outside air, the effectiveness of cooling by cooling pad it's going downhill. So in doing setting cooling pad must pay attention to the humidity level of the outside air of the cage.

Cooling pad very effectively lowers the temperature which is about 70-75% in the ventilation system tunnel, but every 1°C drop will be followed by an addition of about 4.5% moisture. While the ideal humidity needed in the cage closed house is 70%. If the humidity in the cage is high (>70%) it will have an impact litter cepat basah dan lembap. Sebaliknya jika terlalu kering (<40%) maka akan berdampak terhadap litter the dusty one.

Usage cooling pad at the maximum ventilation period is determined by :

- The minimum limit of air velocity that is in the cage.

- Target minimum temperature required for use cooling pad.

- The maximum limit of moisture generated.

At the time of using the ventilation system tunnel at the stage of maximum ventilation and extreme hot weather then cooling pad can be operated by still paying attention to the comfort of the chicken that looks, in addition to looking at the numbers that read on thermometer or control panel. Because the comfort comes from the combination of temperature, air speed, and humidity in the cage.

If the humidity of the cage is high to the limit where cooling pad it must be turned off, then it is very important to maintain its maximum airspeed. Air velocity and air exchange are the single best way to keep chickens comfortable. Chickens will be more comfortable with air velocity and air exchange than evaporative cooling through cooling pad.

Application of ventilation stages closed house suitable for the age and environmental conditions of the cage and the right arrangement of the ventilation system is the key to getting the best performance in the maintenance of chickens broiler. Greetings.