On the cage layer closed house the microclimate conditions inside the cage can be controlled or controlled by a ventilation system that works automatically. The microclimate in the cage includes temperature, air velocity, and humidity. Of the three microclimate parameters, air humidity is the most difficult environmental condition to control, while temperature and air velocity are relatively easier to control.

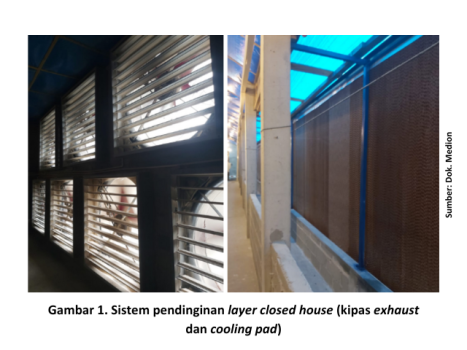

Air temperature inside the enclosure layer closed house can be set or adjusted by adding a heater if the conditions are cold, while to lower the temperature of the air in the cage can be added air velocity. The process of lowering the temperature in the cage closed house can be done by adding air speed using a suction fan/exhaust fan for example, multifunction. Temperature reduction can also be done by utilizing evaporative systems such as by installing Cooling Pad.

Stages Of The Cooling Process

Cooling process inside the cage layer closed house aims to remove hot air or lower the temperature of the air in the cage. The decrease in heat in the cage is adjusted to the target temperature in each period of keeping chickens layer. Cooling process inside the cage layer closed house it is divided into two stages of cooling.

The first stage of cooling is by utilizing air velocity or air circulation (mechanical cooling). The second stage of cooling is by utilizing the evaporation process (evaporative cooling), it can happen because the hot air will go through a wet area or an area where there is a flow of water. The stages of the cooling process must be carried out sequentially to maintain the comfort condition of the chicken and the performance of the chicken layer. Stages of the proper cooling process in the cage layer closed house are as follows :

1. Mechanical Cooling

This mechanical cooling is the first cooling stage or process carried out in the cage closed house. This cooling process is to increase the rate of air velocity or air circulation so that it will be created wind chill effect or the effect of cold wind. Wind chill effect is the effect of a decrease in temperature felt by chickens due to gusts of wind on the surface of the body or chicken skin.

Cage layer closed house a good one must be able to produce the air speed needed by chickens or that is suitable for chickens. Enclosure system closed house you must also be able to change theair exchange) occurs in the right duration. Definition of the change of air in the cage closed house the entire volume of air in the cage must have been removed and replaced with new air within a certain time.

The cold wind effect of this mechanical cooling process apart from the influence of air velocity, is also influenced by chill factor. Chill this factor is very dependent on the age of the chicken, meaning the larger the chicken or the increasing age of the chicken then the value chill the factor will decrease. Value chill factor for small chickens or DOC chickens can reach °8°C and the value chill factor for adult chickens will decrease to 2°C.

Of value chill factor this can account for the impact of wind chill effectit is directly proportional to the speed of air. The higher the airspeed, the higher it will be wind chill effect- his. With wind chill effect we can know the effective temperature felt by the chicken is the temperature that is read in the cage reduced by the value wind chill effect.

Air velocity inside the cage layer closed house must be adjusted for age or maintenance period. In the period starter air velocity of about 0.3-0.5 m/ s, in the period grower the air velocity is about 0.5 – 2.0 m/S, and in the layer period the air velocity is about 2.0-2.5 M/s. If the air speed exceeds the target, the chicken will feel cold and will affect the performance of the chicken layer.

Conversely, if the air speed is less than the target, it will affect the air quality in the cage and the temperature becomes higher than the target should be. Low air speed will also have an impact on high air humidity levels because there will be a lot of air humidity levels that cannot escape or are trapped in the cage.

2. Evaporative Cooling

Evaporative cooling is done after the mechanical cooling process in the cage is maximized. Maximum mechanical cooling is limited to the maximum air speed that can be accepted by the chicken's body at any age of its maintenance. If mechanical cooling is maximized, evaporative cooling can be done by operating cooling pad system.

Cooling pad system it consists of several parts including cell pad, rain maker, pumps and cisterns. This cooling system is utilizing cell pad which is flowed with water so that the hot air that enters the cage will go through a gap or hole cell pad which is already wet and evaporation will occur. With the evaporation of water, the heat in the air will be captured by the surface of the cell pad that has been wet and the air temperature becomes lower or becomes cold.

This evaporative cooling significantly lowers the temperature in the cage, but also negatively affects the increase in air humidity (%RH). Each temperature in the cage drops 1°C due to the occurrence of evaporative in cooling pad, then the air humidity will rise by about 4-5%. The efficiency of evaporative cooling is greatly influenced by air humidity. When the air humidity is high, then the evaporation efficiency will be low.

Usage cooling pad will increase the humidity of the air in the cage. Therefore, the use of colling pad it must be controlled by temperature, air humidity and air speed. Select a control system that is able to adjust automatically so as to control cooling pad based on air velocity, air humidity, and air temperature.

When the air humidity in the cage reaches 80%, the pump cooling pad must be off or off. This setting should be adjusted by careful observation of the behavior of chickens. If most of the chickens have panting, then it is an indication that the air humidity in the cage is too high. When the air humidity in the cage is high, for example 85% and the temperature in the cage is 30°C, it is not recommended to use cooling pad, but the airspeed can be increased in advance according to the maximum limit of airspeed in each maintenance period.

Evaluation Of The Cooling Process

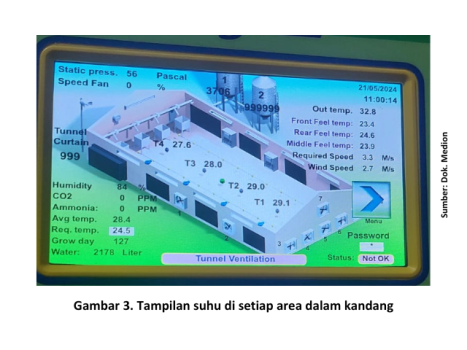

Proper cooling system inside the enclosure layer closed house adalah mampu menurunkan suhu kandang sesuai dengan target suhu kebutuhan ayam, sehingga ayam merasa nyaman dan produktivitas akan optimal. Kandang yang ideal mempunyai selisih suhu bagian depan dan belakang relatif kecil yaitu di bawah 2°C. Selisih suhu yang ideal tersebut (<2°C) harus terjaga sepanjang pemeliharaan ayam.

The cause of the temperature difference is for example the distribution of air that is not evenly because it is blocked or the occurrence of blocking, fan performance exhaust the difference is not in the size of the air intake (inlet) with an operating fan (running). If the temperature difference between the front and back is more than 2°C, several factors must be checked and then immediately evaluated or repaired.

Ideal temperature for the cage layer closed house di periode produksi adalah sekitar 21-25°C dengan kelembapan (RH) <80%. Untuk daerah tropis pendinginan dengan sistem mekanis dan evaporatif ini harus diperhatikan tahapannya, karena jika tahapan pendinginan tidak sesuai justru akan berdampak terhadap peningkatan kelembapan. Kondisi kandang yang sudah lembap akan membuat suhu efektif atau suhu yang dirasakan ayam menjadi lebih tinggi dari suhu yang terbaca.

Some things that can be the cause of non-uniform temperatures and corrective actions include :

a. Decreased fan capacity

The speed at which the air is cooled (wind speed) is produced. The air in the room is heated to a cool temperature (wind chill effect). Ideal airspeed in the cage layer closed house the production period is about 2-2.5 m/s. If the air speed is lower than the target, the potential for overheating of the chicken will occur and can affect the productivity of the chicken.

Therefore, a fan must be selected that has a capacity that is in accordance with the desired air speed target. The capacity of this fan depends on the size and type, for example, a fan Multifan Cone size 50.5 inch, type V4D13E1 w/cone has a suction power of 42,000 m3 / hour.

Aside from the capacity and size of the fan, the number of fan units installed is also important to take into account because it will affect the total air and air velocity produced. The determination of the number of fans must be adjusted to the dimensions of the existing enclosure. The dimensions of the cage are calculated from the cross-sectional area of the cage (cross section areait is determined from the width of the cage and the height of the cage.

To maintain optimal fan performance, maintenance or maintenance the routine. Fan maintenance including maintaining cleanliness shutter, tightness van belt, checking motor condition, blade, and pulley.

Suction fan maintenance/exhaust fan among them are :

- Make sure there are no obstructions around exhaust fan

- Make sure the fan noise, rotation direction and speed are normal

- Check no friction blade to frame

- Make sure shutter perfect opening

- Ensure tightness V-belt fan

- Ensure the tightness of the Bolts

- Give lubricant (grease) on the rotating part

- Clean fan from dust, fluff and foreign objects

- Replace V-belt the aus

- Ensure tightness pulley and blade

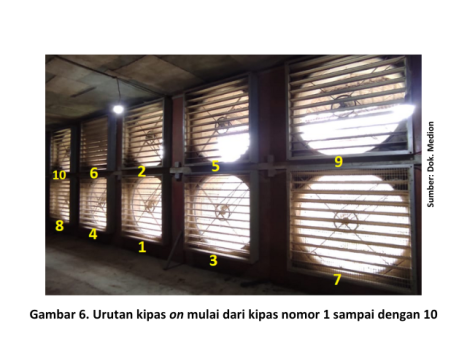

b. Fan sequence position on improper

Fan sequence position on will determine the distribution of air in the cage. If the order of the fans is not right then the air distribution is unbalanced or uneven in all areas in the enclosure. The uneven distribution of air will make the temperature conditions in the cage become not the same or the chicken will experience wind chill effect different. Fan sequence on the ideal can be started from the middle position and then widened to the left and right Alternately, if the location of the multilevel fan then the position on it should also be sequential between the fans that are below alternating with the fans that are above.

c. Imbalance of ventilation

To get the optimal air speed and in accordance with the capacity of the fan installed in the enclosure, it takes a balance between the area of the intake air area (inlet) by the number of fans operating or on (outlet). With its unbalance inlet with the outlet for example, an opening area occurs inlet excess, it will cause the air velocity to be lower and it affects the temperature of the cage to be higher than the desired target.

Other impacts arising from imbalance inlet and outlet is the increased humidity in the cage because the moisture content in the air will settle a lot in the cage and not immediately wasted due to low air velocity. This ventilation balance must be maintained at all times so that the total air and air velocity in the cage are always in accordance with the air needed by the chicken.

Air velocity in the area inlet is about 2.0 m / S for the area inlet installed cell pad with type 45/45 and the ideal balance between inlet and outlet. For tropical areas such as in Indonesia, mechanical cooling is highly recommended using high air speeds even for chickens layer it can reach 2.5 m/S and adult broiler chickens can reach 3.2 M / s. The high air velocity must be balanced between the area inlet with the number of fans on so that the total air in the cage remains sufficient and the air distribution can be evenly distributed throughout the area in the cage.

d. There is a gap (blocking)

Obstacles or blocking either inside the cage or outside the cage (in front of the inlet) will have an impact on the amount of air that is reduced and also the air velocity becomes lower. Therefore, make sure the area in the cage there is no material or object that blocks the flow of air, and avoid the area in front inlet there are obstacles such as buildings, walls, or trees that block the air that will enter the cage.

If there is an airflow resistance in the cage, then in the area there will be a dead wind (blank spot) and the temperature will rise. The effectiveness of mechanical cooling in such areas becomes not the same as in other areas.

Obstacles or blocking in the barn layer closed house should be minimized or eliminated due to the cage layer it also contains cages or battery which makes the air pressure in the cage to be very high in the range of 20-50 Pascal. If these conditions are encountered obstacles, it will have a significant impact on the air flow produced.

e. Cooling pad not wet evenly

Cooling pad uneven wetness will affect the effectiveness of cooling is not optimal. Surface parts cell pad the wet will evaporate while the cell pad the dry does not occur evaporation. Decrease in air temperature through cell pad it becomes not optimal because the incoming air is still mixed between cold air and hot air.

Parameters that can be used to determine the condition cooling pad the wet evenly is by touching the surface area cell pad. If the surface layer cell pad the touch is wet or the presence of running water then the wetting can be stopped immediately or the pump cooling pad off. Cell pad which has been evenly wet will have an impact on optimal evaporative cooling.

Also note the cleanliness of cell pad, because it can cause the surface area for evaporation to be narrower so that the effectiveness cooling pad become decreased. Cell pad can get dirty because it is caused by dust or dirt on the surface cell pad or it can be from cobwebs covering the surface cell pad.

Care or hygiene of cooling pad should be scheduled regularly include cleaning or brushing the surface cell pad with a soft-bristled brush or cleaning is done by spraying with low pressure water so as not to damage the surface cell pad. Condition colling pad it can also decrease its evaporation rate because there are deposits of scale or minerals on its surface that come from the water used to wet it cooling pad.

Therefore, water quality is also important to note because it will also affect the condition cell pad. The smell of cell pad this is also caused by a blockage or dirt in the holes of the rain maker pipe, so that the water flow is uneven or clogged resulting in cell pad not wet thoroughly. Anticipatory of this is by cleaning or flushing from pipes rain maker and make sure there are no blockages or dirt in each of the holes.

This evaporative cooling is greatly influenced by how effective the entire area is cooling pad able to undergo the evaporation process. The evaporation process occurs if cooling pad flowing water that makes the entire area cell pad getting wet.

Determination of the duration of the wetting process cell pad this is based on how long the entire surface area cell pad wet evenly. While determining the duration of the drying process cell pad or pump cooling pad off is from how long cell pad began to dry. Determination on-off on the pump cooling pad improper conditions will make the cage more humid and cause the effective temperature to be higher.

Thus, at a glance, information related to factors that affect the effectiveness of cooling in layer closed house cages and appropriate corrective actions so that the cooling process in the cage layer closed house can be optimal. With optimal cooling and in accordance with the target required chicken layer chicken productivity will be optimal as well. Hopefully it can add insight to all of us. Success always.