Feed is an important part of the livestock industry. Quality feed helps livestock achieve optimal performance. Good feed quality needs to be maintained since the process of receiving raw materials, mixing feed and storage. However, the facts on the ground show that the quality of feed in circulation is still experiencing a decline in quality. One of the causes of deterioration in feed quality is improper storage.

Good feed storage will maintain the nutritional content in the feed is maintained. So the aspect between the storage building and its management needs to be considered. Damage that occurs during storage include moldy feed, rancid feed and pest damage.

Terms related to good storage of feed

The purpose of feed storage is to maintain the best possible nutrient content within a certain period of time. The longer the feed is stored, the higher the risk of damage so it is necessary to pay attention to the conditions and management of feed storage. For farmers who use the technique self mixing, the aspect of feed storage becomes more crucial because all processes related to feed are done by yourself.

1. Watch the water level

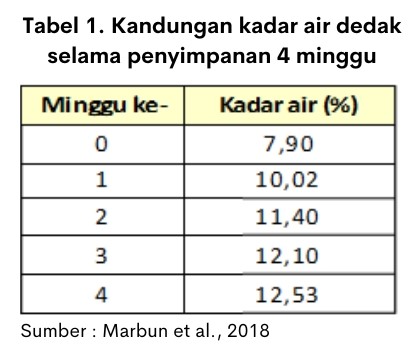

The moisture content can increase during the storage process due to temperature, humidity and prolonged storage. The higher the moisture content of the feed causes the fungus to easily grow and multiply so that the nutrient content in the feed is reduced.

In general, a good feed has a maximum moisture content of 14%. If you get raw materials with water content > 14%, immediately dry with a special dryer or with the help of sunlight (for 2 days). If both are not possible, make stock settings and use them as soon as possible. Add mold inhibitor like Fungitox, contains organic acids that make the atmosphere around the fungal cells become acidic so that the growth of fungi in the feed is inhibited. In addition, the presence of an aluminum silicate complex will bind mycotoxins and prevent their negative effects.

2. Discipline Quality Control

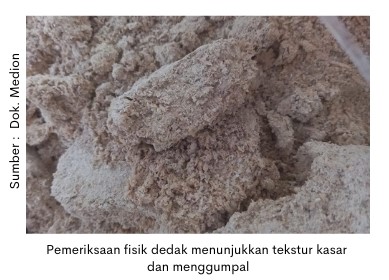

Checking the quality of feed is carried out from the beginning of the arrival of feed. Some important information such as no. batch, name supplierdate, date and amount of feed should be noted. This aims to facilitate farmers in tracing cases when there is a disruption in production due to feed and facilitate the management of feed stocks so that they are not stored for too long. During the storage period, do quality control routinely on perishable raw materials such as corn and Bran (1 week), while the feed is not perishable can be done 2 weeks. Quality control it can be done physically, such as observing color, odor, particle size, and mold contaminants.

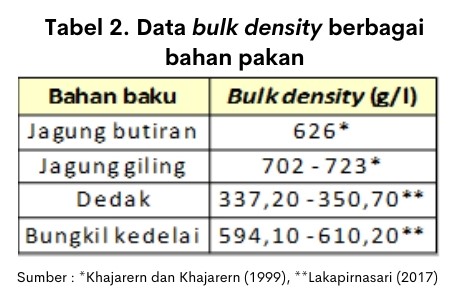

While the chemical examination can be done by proximate test (include water content, crude protein, crude fat, crude fiber), calcium levels, phosphorus levels and gross energy. In addition, there is also a test Phlorotest to test for husk contaminants on Bran or Bran. Microscopically, the type of raw material can be observed through a microscope with a magnification of 90-500 times. Testing bulk density or specific gravity is a test that is easy to do in the field. Test bulk density done by taking a number of feed ingredients and then put in a container that has a known volume of EG 1 liter, make sure there is no cavity formed. After that, the feed ingredients are weighed. Bulk density obtained by dividing the weight of the feedstock by the volume of the feedstock in the container with units (g/l).

3. Provide feed stock as needed

The longer the feed is stored, the risk of deterioration in feed quality, especially those that contain high levels of water and fat. For example, feed ingredients such as oil, coconut cake and Bran have a high crude fat content so that they are susceptible to oxidation as a result of which the feed becomes rancid. Rancid feed causes the breakdown of fat-soluble vitamins such as vitamins A, D, E and K and reduces palatability. Ideally, chicken feed is stored for no more than 21-30 days from the date of production, the goal is that the feed runs out quickly and is not stored for too long. While the feed ingredients that have not been mixed long storage depends on the conditions during storage.

4. Keep the feed warehouse clean

A dirty shed is a favorite place for fleas, rodents and insects to breed. The disadvantage is a decrease in physical and chemical feed. Perform regular sanitation and fumigation in the feed warehouse. Leave a distance of 50 cm from the edge of the wall to the feed. Besides functioning to keep the feed is not damp also to reduce the presence of mice. Avoid repeated use of sacks, if they are to be reused, clean them of previous feed residues and dirt that is still left behind.

Building Standards and their management

Feed warehouse is a building that protects the feed from external influences such as the sun/rain and facilitate the supervision of feed. Building a feed warehouse needs to pay attention to several aspects related to storage so that the storage process can run in accordance with the purpose of storage. Here are some standard aspects of warehouse storage.

1. Building location

The storage shed should not be directly adjacent to the chicken coop but easily accessible, making it easier to transport from the barn to the cage. It is aimed at preventing contamination from the cage to the feed. The floor of the building is made higher than the ground so that the shed is free of water.

2. Building size

There is no specific standard that regulates the size of the feed warehouse, adapted to the needs of each. The spacious warehouse makes it easy to adjust the distance between the feed piles. Warehouse should not be filled more than 70% of maximum capacity, so that there is still room for air circulation. The barn is made closed to prevent outside influences such as leaks and the presence of outside animals that enter the barn.

3. Sufficient ventilation

The problem of damp warehouse is caused by inadequate ventilation. A good Warehouse should have a temperature range of 25-32°C with a maximum humidity of 70%. Installation turbine ventilator on the roof of the shed can add air circulation. In addition, efforts to increase air circulation by adjusting the distance between the feed pile and the installation pallet with a height (5-15 cm) as a base to increase circulation and prevent feed from absorbing water from the floor. Stack pallet up to a maximum of three pallet, and each pallet contains six piles of feed.

4. Lighting

Lighting in feed warehouses can come from sunlight and lamps. Good lighting makes it easier for farmers in quality control and prevent the growth of fungi and other pest activities such as rodents and insects. But it should be noted that the incoming sunlight does not directly hit the feed.

5. FIFO and FEFO management

FIFO storage systemsFirst In First Out) is a storage system using feed in accordance with the order of arrival. This is where the importance of feed recording when it comes. However, if the food is damaged or expired (such as feed additiveif you do not want to use the system, use the FEFO system (First Expired First Out), so it is important to do quality control routinely. The faster the handling on the damaged feed the lighter the effect.

Feed storage is one of the critical points that affect feed quality. Decreased nutritional value and fungal contamination is the result of improper storage of feed. Storage errors can be minimized by implementing good storage arrangements so that economic losses due to feed damage can be avoided. Similarly, information about good feed storage management. May be useful.