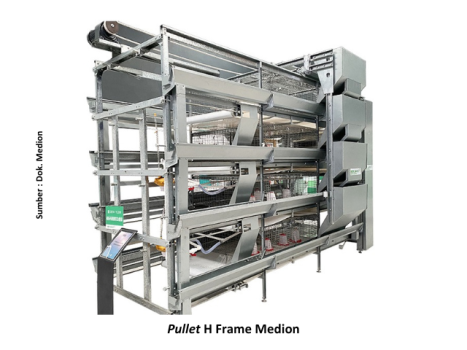

Enclosure system closed house is a modern enclosure technology designed to optimally control the enclosure environment. This system allows farmers to better regulate temperature, humidity, wind speed and equipment components. Application of the system closed house on the cage pullet laying the right will produce quality pullet quality and optimal production.

Not only ventilation, on the system closed house pullet laying also applies automatic systems for other equipment components such as feeders, drinkers, manure systems, egg collection systems, lighting that can be controlled with a control panel. The automation process will certainly make it easier for farmers to maintain and streamline labor. Moreover, the characteristics of modern layers are now more sensitive to weather changes, feeding patterns, drinking water quality, lighting will be minimized with a cage system closed house which makes the chicken more comfortable. Target in Phase pullet will be easily achieved if the comfort of the chicken can be maintained by management closed house pullet the right one.

Parameters pullet the quality can be seen from the weight, uniformity and mortality. Weight loss pullet must be achieved every week according to the standard strains specified weight (⑧10% of the standard weight). Body weight according to the standard will correlate with the optimal development of organs, skeleton and muscles. Uniformity must also be considered so that one chicken with another chicken in terms of weight, skeleton, and adult sex the same/simultaneously. A chicken is said to be uniform if its uniformity reaches >85%. Death must also be considered because the more dead means that the number of egg printing machines (laying hens production) will be reduced. Mortality standards of laying hens in phases pullet between 2%. To achieve these targets required management closed house laying phase pullet the right one. Management closed house pullet laying phase is divided into 3 namely cage preparation, management starter and grower.

DOC Cage preparation

Before the maintenance period, the cage closed house must be prepared in advance. Preparation of the cage includes the process of cleanliness of the cage, cage rest, equipment preparation, continued the process pullet-in. Cage preparation schedule must be made from the stage of excrement to the stage pullet-in. This is so that the preparation of the cage can be completed on time with a predetermined time.

Make sure the electricity in the cage is off before starting cage cleaning. The cleanliness of the cage starts from the stage of cleaning the manure. The droppings begin to be cleaned and removed from the cage. Dirt systemmanure belt and scrapper) also cleaned of impurities attached to the fibers or with a sharp object and then sprayed with pressurized water.

After finishing cleaning the manure, start to enter the stage of cleaning the cage and equipment. The following are the stages of cleaning the cage and equipment:

- Washing cages and equipment with detergent

- Rinsing with clean water

- Disinfection of cages (Sporades and forms)

- Liming floors and aksses in cages with active lime (quicklime)

- Fumigation

- Cage rest of at least 14 days is calculated starting from the cage is clean (already disinfected)

- External cleaning of the enclosure (weeds, bushes, puddles, garbage, pest control)

The necessary equipment is prepared in advance. Feed, drinking, lights, manure systems, cage curtains are checked in advance for availability and if damaged immediately for repair. Before starting maintenance, a test run of the ventilation system is carried out such as checking the fan capacity, maximum wind speed in the cage, air exchange in the cage, flatness of wind speed so that maintenance runs well and there are no problems.

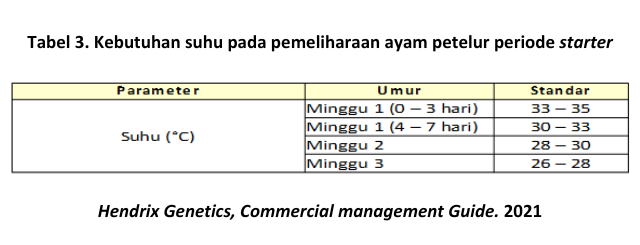

Heating (pre-heatingperformed prior to arrival Day Old Chick (DOC). Pre-heating aims to condition so that the temperature of the cage reaches a comfortable temperature DOC. DOC's comfortable temperature upon arrival ranged from 33-35oC. Generally pre-heating treatment is carried out for 1-2 hours, but in some high-altitude areas it can take longer. After doing pre-heating required to perform flushing on line nipple warm water in nipple it can be replaced with water of normal temperature.

Things that must be considered when receiving DOC is to do weighing, quality control, then do a DOC stocking. Do it sampling weighing 0.5 - 5% of the total population to find out the average weight of the DOC who came. Perform weighing as well as selection on stunted, weak chickens, dry legs, and omphalitis. Do it culling on DOC who can no longer be productive such as eyes closing, crooked beak, red hock, severe dry feet. After doing quality control do stocking DOC starting from tier Middle according to the standard density of each age and dimension cages then do thinning every week based on body weight.

At the beginning of the starter period maintenance of laying hens is very important because in this period there is a development of organs such as digestive organs, respiration, immunity, skeleton and feathers. In this period thermoregulation also the chicken is not perfect so the chicken has not been able to adjust its body temperature to the temperature of the surrounding environment. Management that must be considered in the period starter among others:

1. Ventilation Management

At the beginning of the day (starter period), the stages of ventilation applied is the minimum ventilation in which the period starter this temperature from outside the cage is below the desired target temperature of the cage (33-35°C), so that in this period has not required the effect of wind speed to cool the temperature inside the cage (wind chill effect) and the cooling effect with cooling pad. Less minimum ventilation will have an impact on overheated chickens and lack of oxygen while excess minimum ventilation will have an impact on cold chickens. There are several factors that must be considered in the application of minimum ventilation, among others:

a. Required amount of air

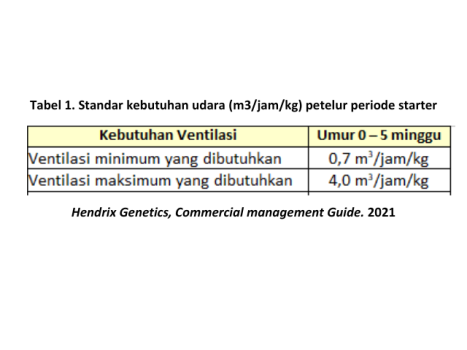

The need for air for laying hens in the starter period will determine the number of fans that should be on in general intermitten/on-off nor the fan on continuously/direct. To calculate the fan requirements are guided by the standard air requirements (Table 1) and the capacity of the fan installed in the enclosure.

If the fan needs running is still below 1 unit then we operate intermitten/on-off. The need for air in the cage we can calculate based on:

- Chicken population

- Weight loss

- Air requirement standard

- Installed fan capacity

An example of calculating fan requirements is as follows :

DOC Weight = 37 grams

Population = 45,000 head

Fan capacity = 42,000 m3/h

Min air requirement / kg = 0.7 m3/kg/h

Cycle timer = 5 minutes

Air requirement = population x chicken weight x minimum air requirement

= 45.000 ekor x (37 g/1.000) x 0,7m³/kg/jam

= 1.166 m3/h

Number of fans = air requirement / fan capacity

= 1.166 m³/jam / 42.000 m³/jam

= 0.028 units

Intermittent on = Jumlah kipas x timer

= 0.028 units x 5 minutes

= 0.14 minutes or 8 seconds

Intermittent off = Timer – durasi off

= 5.0 minutes-0.12 minutes

= 4.84 minutes or 292 seconds

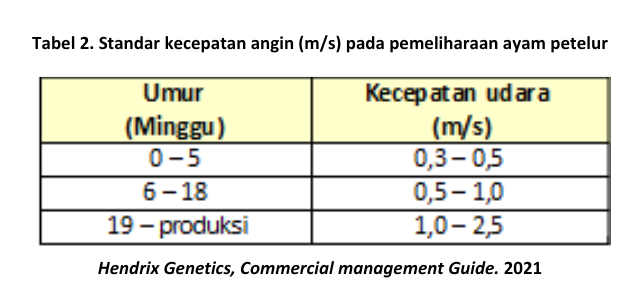

With the help of a vacuum cleaner (air exchange) on a standard cage (120 m x 12 m x 4 m) it will take about 5-8 minutes or with a wind speed of 0.3-0.4 m/s. The standards for wind speed in the maintenance of laying hens are as follows :

The temperature in the cage also needs to be considered, especially in the starter period because the chicken's thermoregulation is not perfect and still needs heating. The temperatures required for laying hens of the starter period are as follows:

To even the distribution of heat in the cage can be added with a stirring fan so that the heat in the cage will soon spread evenly throughout the area in the cage.

b. Ventilation balance

Ventilation balance is the suitability between inlet or where air enters with outlet or where the air comes out. Inlet the type of tunnel ventilation is made in the area cooling pad and set the width of the opening based on the number of fans on. Aperture size inlet this is the entrance of air into the inner area of the cage. If the inlet area is open too wide then the incoming air flow from cooling pad will be very low wind speed and vice versa if the inlet opening is too small it will result in wind speed will be higher than the expected target.

The determination of the inlet opening is guided by:

- The number of fans on

- Target wind speed at the surface cell pad

Calculation example :

If 1 fan 50 inch running with a suction power of 42,000 m3 / hour and the target wind speed in the inlet area of 2.0 m / s, the inlet area is :

Inlet area = fan capacity/wind speed in cell pad

= (42.000 m³/jam)/(2,0 m/s)/3.600

(convert seconds to hours)

= 5.8 m2

Jika area cooling pad adalah = panjang 8 m x Tinggi 6 m

Maka lebar bukaan inlet = Luas inlet / panjang cooling pad

= 5.8 m2 / 8m

= 0.7 m

Errors that are often found in the cage closed house is a failure to arrange openings inlet and cycle on – off fan. If the inlet opening is too wide, the incoming air will lead directly to the bottom area due to the low speed and the air pressure in the cage also drops. If the openings inlet too narrow, then the wind speed in the area inlet it will increase then in the middle area or back of the cage will occur low wind speed even dead wind (dead spot)

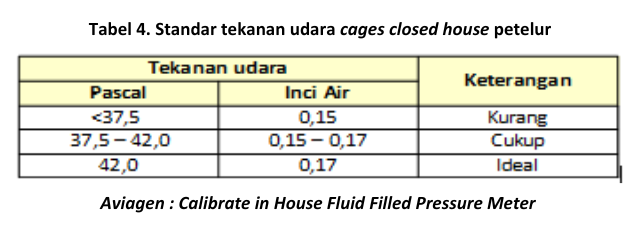

c. Air pressure

Air pressure in the cage depends on the dimensions of the cage (Width x length x height), the area inlet, blocking cages and also from the leakage of cage curtains. Good air pressure for laying cages closed house is 0.17 inches of water or 42 Pascals. Cages with a width of more than 12 meters will be more difficult to obtain standard air pressure. Then it is recommended for a wide cage coupled with a circulation fan installed inside the cage.

Tekanan udara yang rendah (<0,15 inci air atau <37,5 Pa) bisa diterapkan pada kandang dengan kelembapan yang rendah/kering (<60%). Ukur dan pantau terus kecepatan angin secara teratur. Jika terjadi masalah ventilasi di dalam kandang harus segera dicari solusinya seperti tirai-tirai yang bocor harus segera ditambal. Tekanan udara yang tidak ideal akan berdampak pada keseragaman kecepatan angin yang kurang. Standar tekanan udara dapat dilihat pada Tabel 4.

2. Drinking Water Management

The composition of the chicken's body is 70-80% water. Water is very important for chickens besides being a constituent of the chicken's body as well as regulating body temperature, especially DOC who has not been able to regulate his own body temperature. Water can help keep the chicken's body temperature stable. Water serves as a heat transfer medium and helps distribute heat to the environment. Therefore, it is important to pay attention to the parameters of the quality and quantity of drinking water on the farm.

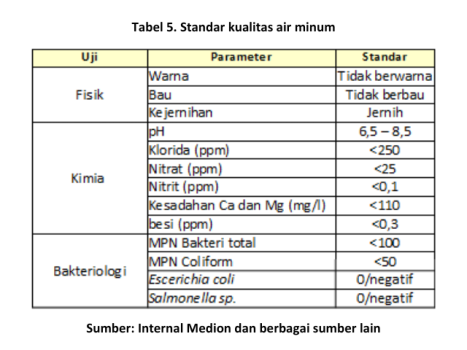

a. Drinking water quality

Often overlooked, good water quality is very important considering that water is one of the sources of pathogenic microorganisms. Drinking water quality must be maintained from biofilms, bacteria, scale, fungi, algae while maintaining the physical, chemical, and biological quality of drinking water. The following physical,chemical, bacteriological qualities can be seen in Table 5

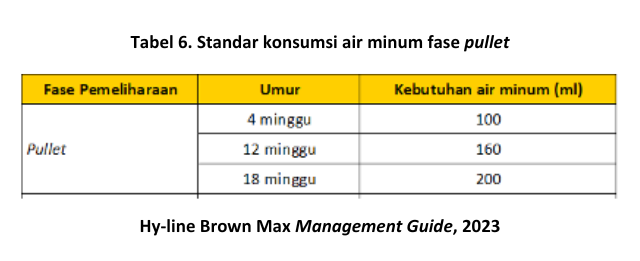

b. Drinking water quantity

In terms of quantity, it is also important to note that the water intake is in accordance with the drinking water needs of laying hens at every age. The height of the nipple line at the time of chick in is at eye level so that the chicken can easily adapt and find a place to drink. Then with age it starts to be raised until the chicken drinks from the beak to the nipple forming an angle of 45o. The water pressure setting in the regulator refers to the drinking water needs of chickens. The water pressure is too low to cause the chicken is not sufficient for its water needs. Water pressure that is too high can cause leakage in the nipple.

3. Feed Management

Feed is the largest cost component in the maintenance of laying hens. Proper feeding management will provide adequate nutrition for laying hens so that the development of organs and thermoregulation can develop to the maximum. Management of feeding in the starter period must be considered in terms of quality and quantity.

a. Feed quality

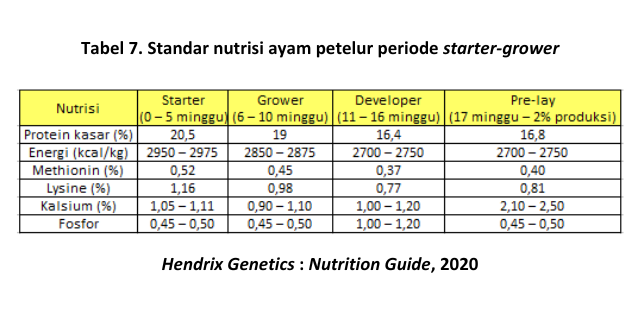

Quality feed is feed that has sufficient nutritional content. Nutritional needs may vary depending on the breed of chicken and the age of the chicken. Each phase of the maintenance of laying hens has its own development chart. Example in Phase starter, the need for protein is highest compared to other periods. This is because in the starter period there is a very high multiplication and growth of cells to support the formation of organs and the achievement of optimal body weight. Here's an example of the nutritional needs of laying hens phase starter-grower can be seen in Table 7.

b. Feed quantity

To optimize the absorption of egg yolk should be early feeding (early feeding). Early feeding is done so that the chicken after being stocked in the cage can immediately eat so that the absorption of egg yolk can be maximized.

In the starter period laying hens can be given 4-9x a day ad libitum feed (always available) because in that period the growth is very fast and feed efficiency is very high. The number of feed places must be adjusted based on the population so that there is no competition and each chicken can reach the standard feed intake at any age. The change of feed place must also be done gradually, for example from TRDK (small DOC ration place) to the feed gutter, the transfer is carried out for 3-5 days.

3. Lighting Management

Light is one of the important aspects in the management of the maintenance of laying hens. Especially in the starter period, Light is used to find places to eat and drink, eating and drinking activities, growth and development, and metabolism of Ca and P. Unlike the cage open house which light source generally comes from sunlight and lamps, enclosures closed house just coming from the lights. Cage type closed house it is easier in lighting management so that it can be applied appropriately. Lighting management can be seen from the duration, light intensity, and color spectrum.

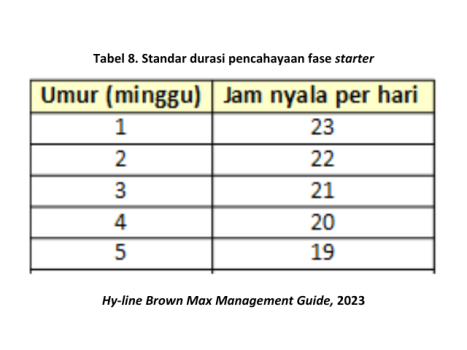

a. Light duration

As a general guide, the duration of exposure during Phase starter gradually reduced per week. Long duration of lighting in the future brooding period, to help optimize feed intake because one of the functions of light is used in eating and drinking activities. The duration of exposure in the starter phase is 19-23 hours. What needs to be considered is the reduction in the duration of the lamp light is gradually reduced by approximately 1 hour. Here the duration of illumination in phases starter can be seen in Table 8.

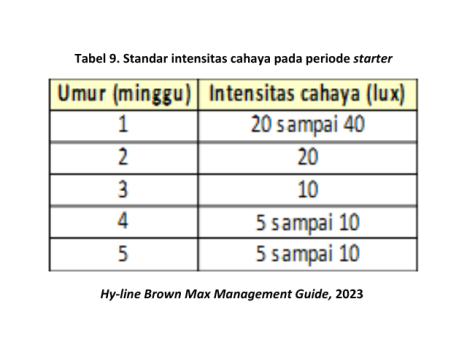

b. Light intensity

Light intensity is an important factor from the first day of maintenance because it helps DOC to quickly recognize its environment, drinking place, and feeding place.

There is a very close relationship between light intensity, physical activity, pecking behavior and feather loss. Light intensity that is too high will increase the nervous system of chickens so that it can lead to increased mortality caused by pecking the cloaca of other chickens (cannibalism). This risk is even higher when coupled with too high a density. The need for light intensity of the first week of 20-40 lux then decreased to 5-10 lux in Week 5.

c. Light spectrum

The color spectrum of light also needs to be considered in the lighting in the cage closed house. The light spectrum is very influential on the performance of the laying hens themselves. We can also adjust the light spectrum easily by paying attention to the type of light source (lamp), wavelength, and lamp temperature. On time pullet the spectrum of light given is blue to green (3,500-4,000 K).

Grower Management

In the phase grower optimal skeletal and muscular development occurs. Skeletal and muscular growth in modern laying hens cannot now be compensated for, which means that they cannot be overtaken if they are lagging behind. Management in phases grower starting from ventilation, drinking water, feed, lighting, and monitoring must be applied appropriately. The following is an explanation related to the management of ventilation, drinking water, feed, lighting in Phase grower.

1. Ventilation management

Stages of ventilation in phases grower next are the stages of transitional ventilation and maximum ventilation. Transitional ventilation is only the transition from minimum to maximum ventilation. The outside temperature is the same as the target and the chicken is still too young so it has not been able to be given maximum ventilation/tunnel.

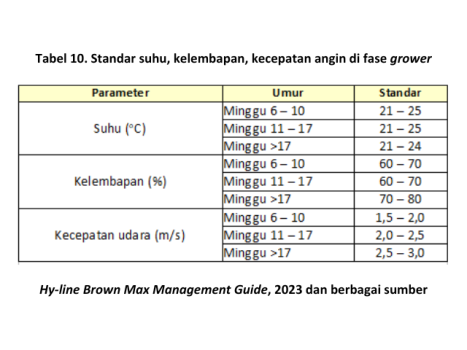

Maximum ventilation is required for laying hens when the temperature in the cage is above the desired target (18-21°C), then the effect of wind speed is needed to cool the temperature in the cage (wind chill effect). Maximum ventilation is applied when the temperature inside the cage is warm to hot by activating cooling pad. Maximum ventilation is operated by adjusting the number of fans on based on the temperature read in the cage. As for the initial settings, the use of cooling pad will be based by a combination of 3 parameters, namely the minimum standard of wind speed, temperature reached, and limited by the humidity it causes. Here is the standard temperature, wind speed, humidity phase grower.

2. Drinking water management

As in the phase starter, in Phase grower drinking water must also be considered both in quality and quantity. Here are some things to consider in drinking water management in the grower phase:

a. Quality and quantity of drinking water

Drinking water quality can be seen in terms of physical, chemical, and bacteriological. Poor water quality will reduce drinking water consumption and chickens can contract diseases through drinking water media. Poor water quality can also damage the system cooling pad dan line nipple so that the equipment becomes not durable. In terms of quantity, drinking water in Phase grower will be more than the phase starter. The water pressure must be adjusted to the chicken's drinking water needs.

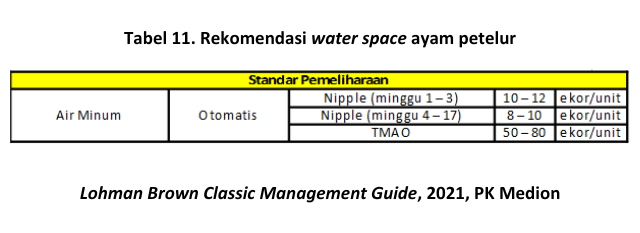

b. Water space

Water space/ chicken access to drinking water is also important to consider in a chicken rearing. Chickens who lack access to drinking water will decrease feed consumption and have an impact on the achievement of target weight and uniformity in the pullet phase. Here are the recommendations water space .

c. Drinking water system maintenance

Nipple used over time there will be dirt, Moss, gravel, and other foreign objects. The first care step when empty cage is to disassemble nipple the dirty then come off after that wash. Once clean, put it back nipple into place. Flushing is the activity of removing water from the place or drinking water channel. Purpose flushing namely cleaning biofilm or dirt that concerns the pipeline so that it can be wasted. Flushing it can be done once a day or 3 times a week. Way flushing can use high pressure water (1.5 to 3 bar) or by using chemicals such as hydrogen peroxide (H₂0₂)/ Bioflush with a dose of 10 ml/100 L of drinking water when the cage contents or with ultrasonic waves (Harsonic).

Likewise with the medicator which is a mixing place for drugs and vitamins. The medicator must be treated by disassembling the medicator and then rinsing the dirt contained in the medicator. If there is a damaged seal immediately for replacement. The medicator hose must also be washed so that the medicator can be preserved.

3. Feed Management

The method of feeding in closed House cages adjusts the feeding behavior of chickens. Chickens have an innate behavior that is selective in terms of feed so that it requires proper management or techniques in order to achieve optimal feed intake. As the chicken grows older, the daily energy requirement will increase. This will affect the feed intake of each chicken.

will get the opportunity to choose a form of feed with large particles (high energy) and a small weight ones will tend to eat the rest (small particles that are high in amino acids and vitamins). To overcome this we can do the selection of feed forms at the time starter using shaped feed crumble then when the phase grower-layer using shaped feed mash/crumble in addition to providing food by making feed cart a total of 2-4 times/day. The speed of Feed distribution will also affect the flatness of the feed. Kecepatan chain feeder 3-6 menit per line. With Fast Feed distribution, chickens will not be selective when chain feeder/feed cart carried out.

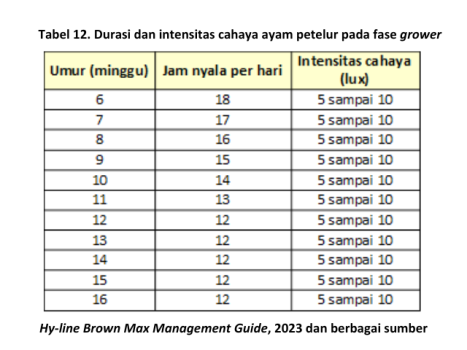

4. Lighting Management

Lighting in Phase grower requires less light duration and intensity compared to phase starter. In the phase grower, the focus switches to the development of the skeletal system, reproduction and preparation for the egg production phase. Too much light in this phase can prematurely accelerate sexual maturity, which can result in chickens starting to lay eggs before they reach optimal body size and weight. Here is the intensity and duration of light in Phase grower.

Simultaneously with the implementation of management closed house in Phase starter and grower, the breeder must perform monitor and assessment. Monitoring and assessment chicken done since DOC-production. One form of DOC monitoring when chick-in check out the (crop fill) on DOC whether the majority of DOC has been filled with feed and drinking water or not. Monitoring chicken is also seen from the distribution of chicken whether the chicken is comfortable or not. The most important thing is that we have to weigh the weight once every 1 Week in the pullet phase in order to know the weight, uniformity, CV then if it is less than the standard we can immediately evaluate and correct it. That way pullet the one in the cage closed house the breeder is a quality pullet.

So at a glance information on how to get pullet quality in the cage closed house hopefully it can add insight and be useful. Greetings.