Uniformity pullet it becomes important because it will determine the achievement of peak egg production. Pullet with high uniformity will start producing eggs at the same time so that the peak of production is relatively easier to achieve. Uniformity pullet we can determine from the achievement of body weight, which is + 10% of the standard weekly body weight. Harapanya pullet the one we maintain can reach >85% uniformity. In addition to body weight, the skeleton pullet and sexual maturity should also be uniform. Evaluation of the uniformity of the framework can be done by measuring the length shank (standard length shank at the age of 13 weeks, which is 100 mm), while sexual maturity can be seen from the optimal growth of Combs and wattles.

Factors affecting uniformity

- DOC's condition

DOC quality is an important factor in early maintenance pullet. Body weight and DOC condition are two main parameters in assessing the quality of DOC. A good DOC has a body weight ranging from 33-37 grams with a normal body condition or not disabled. DOC with low or weak body weight needs to be given special treatment upon arrival at the cage. Awarding Gingertol which contains sorbitol and red ginger extract will help restore DOC's energy after a long trip.

- Provision of quality rations

Ration is a basic need for chickens to grow and develop. Quality rations are rations that have nutritional content that suits the needs at each stage of life.

Addition of calcium grit to the ration pullet will help the growth of the skeleton and digestive tract in particular gizzard. In addition to nutritional factors, target feed intake Daily should always be achieved to produce optimal growth. The remaining rations or even spilled and scattered in the cage will reduce feed intake chicken.

- Availability and distribution of drinking water

The availability of drinking water is as important as the availability of rations, because a decrease in drinking water consumption will also decrease feed intake chicken. It is necessary to pay attention again to the distribution of drinking places for chickens in the cage. Make sure the amount is appropriate, so that the chicken can access it easily.

Replace and regularly check the chicken manual drinking place and place it in each area of the cage. If using a drinking place with the system nipple, make sure there is no nipple which is clogged. The water pressure also needs to be adjusted to the age of the chickens being kept. High water pressure will cause nipple it is relatively heavier to peck, so it is not suitable to be given to DOC and chickens after cutting the beak.

- The right lighting Program

Lighting serves to help chickens find food or drink, giving chickens the opportunity to express their behavior, as well as for growth and sexual maturity. Lighting settings are determined based on the achievement of chicken body weight every week. If the body weight is always reached every week, then we can immediately apply the Lighting program Guidelines. But when the target body weight is not reached, then the Lighting program both duration and intensity can be postponed in advance.

Imposing lighting stimulation on the cock pullet with low body weight can cause chickens to lay eggs earlier and increased cases of cannibalism. This is because the stimulation of lighting will stimulate hormone production so that chickens experience early genital maturity.

- Cage density

The high density of the cage will increase the competition of chickens. Chickens will fight each other for food, drink, and oxygen for their needs. High competition between chickens will lead to non-uniform growth. Chickens that are less competitive will lag behind in growth, resulting in low uniformity. Recommended density for maintenance in postal cages in phases starter ie 20 tail / m2 and in Phase grower 12 tail/m2Isa Brown Management Guide 2021).

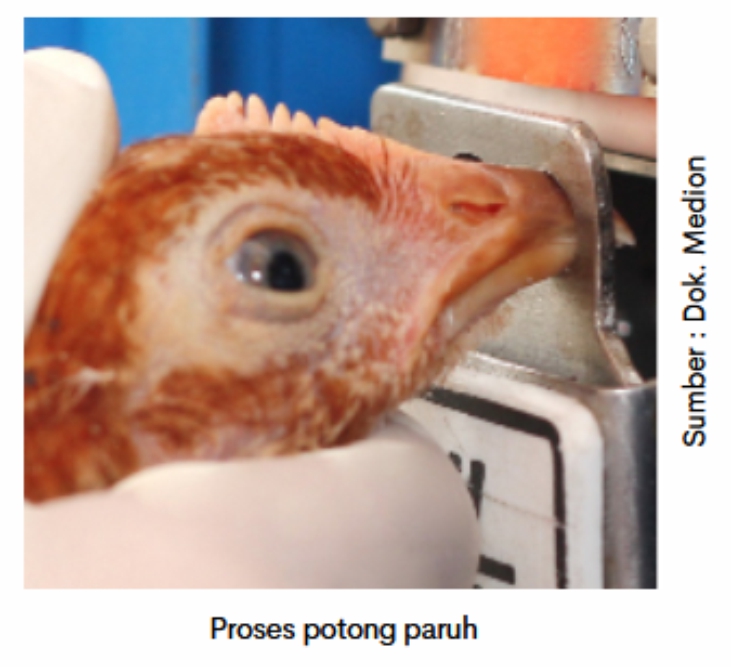

- Cut the beak

Beak trimming in laying hens is aimed at the efficiency of the ration and also at preventing cannibalism. Naturally, chickens prefer feed with large granules. But on the other hand, micronutrients in feed such as minerals are available in the form of mash or fine particles. Therefore, the process of cutting the beak is what will make it easier for chickens to eat feed particles in a finer form. Cut the beak should be done on time and with the right method. Because errors in the process of cutting the beak will make the chicken become stressed and even defects in the beak that have an impact on the decline feed intake and uniformity. Beak cutting can be done on chickens aged 1-10 days and Ika required repeated at the age of 8-10 weeks. The process of cutting the beak must be precise in order to obtain maximum results. The activity of cutting the beak will make the chicken become stressed, so the provision of vitamin K such as Vita Stress in the 48 hours before and after the beak cut it is important to reduce its stress impact. Handling chicken properly when cut the beak and after cutting dip the beak into the solution Neo Antisep to stop the bleeding.

- Chicken health Status

Chicken keeping age layer a long course requires a strong foundation, especially related to health programs. Disease attacks will interfere with the growth and uniformity of the chicken in Phase pullet. Before entering the production phase, make sure the vaccination program is complete and completed. Proper vaccination and treatment programs will help keep pullet stay healthy. Monitoring titer routinely it is important to monitor antibodies in the chicken's body. Prevention of the entry of disease agents from the outside can be done by applying biosecurity that's good.

- Transfer chickens to production cages

Transfer of chickens from the cage pullet to the production Cage becomes one of the processes that make chickens become stressed. Handling rough chickens, extreme environmental conditions during travel, and new housing conditions are stress factors at the time of chicken transfer. The transfer process should be done in the morning to avoid hot weather during the day. When moving into production cages, give the same treatment regarding the type of feed and lighting program as in the pullet cage. This will help the chicken to adapt to the new environment and speed up the period recovery.

Grading to view and evaluate uniformity

The low level of uniformity is often one of the challenges when raising chickens in the phase pullet. Chickens with low body weight and chickens with high body weight need to be separated and given special treatment so that the achievement of body weight can be in accordance with the standards.

Current phase pullet it is quite common to do activities grading chicken to see and evaluate the total uniformity of the chicken we keep. Grading the total chicken is done at the age of 5 weeks and when the chicken is moved to the production cage. The main purpose is carried out grading namely to see the uniformity of the total chickens are kept and classify the chicken according to the achievement of body weight.

Before doing grading, penting untuk menentukan kelompok bobot badan ayam. Bobot badan ayam dapat dibedakan menjadi 3, yaitu bobot badan kurang dari standar (<10% BB), bobot badan standar (+10% BB), dan bobot badan lebih dari standar (>10% BB). Pengelompokan bobot badan ini tidak menjadi standar baku, melainkan dapat disesuaikan dengan kondisi yang ada di dalam kandang.

Chickens that have been classified based on body weight can then we give special treatment to each group. In the maintenance of the battery cage placement of chickens into one of the treatments that can be applied post grading. Chickens from the group of substandard body weights are recommended their placement on the battery of the uppermost battery. With the best air circulation in the battery the topmost battery is expected to chicken feel comfortable so that the target feed intake always achieved and lagging body weight can be pursued. The battery position of the bottom battery is intended for chickens of the substandard body weight group, and the position of the middle battery is intended for chickens of standard body weight.

The method of feeding chickens with substandard body weight also needs to be readjusted. Replacement of the type of feed can be delayed to help its growth and if necessary can be added premix. Additions Mix Plus LGM13A in the feed will help improve the efficiency of feed use so that it can catch up with the weight of the chicken. Density factor can also be the cause of chickens with sub-standard body weight, so it needs to be re-evaluated the existing density and should be adjusted to the guidelines of each strains.

Chickens with a body weight above the standard also need to be given special treatment to control body weight so as not to overweight at the time of entering the production phase. In chickens with a body weight above the standard can be held the addition of the amount of feed in the following week or the amount equated to the previous week.

Uniformity pullet become an important point to achieve optimal production performance. High uniformity can be obtained by one of them doing grading chicken.