Pertanyaan dari Ibu Tias – by Email

Coconut cake and palm oil cake have high fat content, how are the tips to be given to poultry?

Answer

Thank you Ms. Tias for the question submitted. Coconut cake and palm oil cake have in common that they contain relatively high crude protein. Both are by-products of the manufacture and extraction of oil.

Both feed raw materials can be used as a partial replacement of the use of soybean meal.

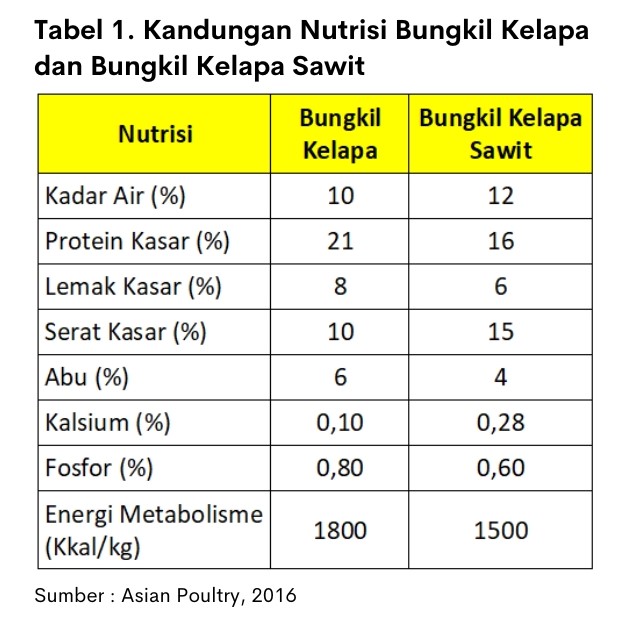

The high fat content in coconut cake and palm oil cake is able to supply relatively high metabolic energy so it is good for increasing the weight and size of eggs. Here is the nutritional content of coconut cake and palm oil cake.

On the other hand, the crude fat content is too high resulting in feed formulations become rancid due to oxidation reactions. Oxidation reaction is a reaction that arises from the reaction of unsaturated fatty acids meet with oxygen and is accumulative.

The result of rancid feed is to lower the level of palatability, lower levels of fat-soluble vitamins such as vitamins A, D, E, and K, lower energy levels in the feed and shorten the storage period. In addition, the content of coarse fiber in coconut cake and palm oil cake should be noted.

Here are some tips for giving coconut cake and palm oil cake to poultry:

Note the restrictions on its use

The limit on the use of coconut and palm meal in poultry feed is 10%. In addition to the high crude fat content, the presence of contamination such as Shell and coconut skin is very hard to cause perlukaan on gizzard and intestines. Coarse fiber that can be digested by chickens is a maximum of 7%, while in ducks it is a maximum of 10%. The crude fat content of the formulation for poultry is generally a maximum of 7%. In order to reduce coarse fibers, the use of oil palm cake with some treatment such as sieving and milling, fermentation and hydrolysis processes.

Raw material storage control

The high fat content in the raw material causes the feed to experience rancidity due to the oxidation process. The oxidation process increases due to an increase in temperature and humidity in the storage room. Set the storage room temperature 30-34 °C and humidity First In First Out (FIFO) is to use the feed that comes first and use feed of poor quality in advance even though the new coming first expired first out (FEFO). Use pallet under the pile to increase air circulation so that the feed material is not damp.

Use of antioxidants

The high fat content in the raw material causes the feed to experience rancidity due to the oxidation process. The oxidation process increases due to an increase in temperature and humidity in the storage room. Providing antioxidants in feed raw materials or feed containing high fat aims to reduce the rate of oxidation.

One example of herbal antioxidants in feed is Oreganum vulgare as contained in Optigrin. In addition to the presence of antioxidants, the advantages of Optigrin is able to suppress the growth of pathogenic microbes (alternative AGP), contains immunostimulants and safe does not cause residue and resistance.

In addition to the addition of feed and feed raw materials, antioxidants can also be mixed in premix. Products such as Top Mix and Mix Plus already contains antioxidants. Awarding premix also intended as back up reduced nutrition due to rancidity so that performance increases.