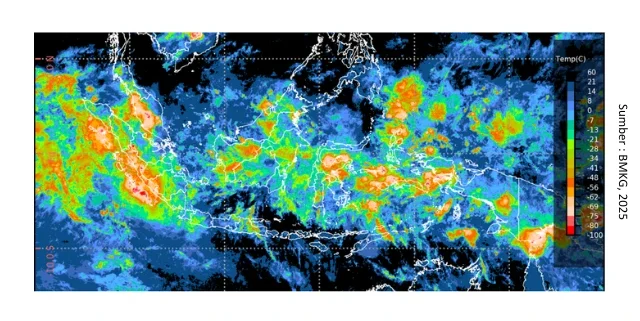

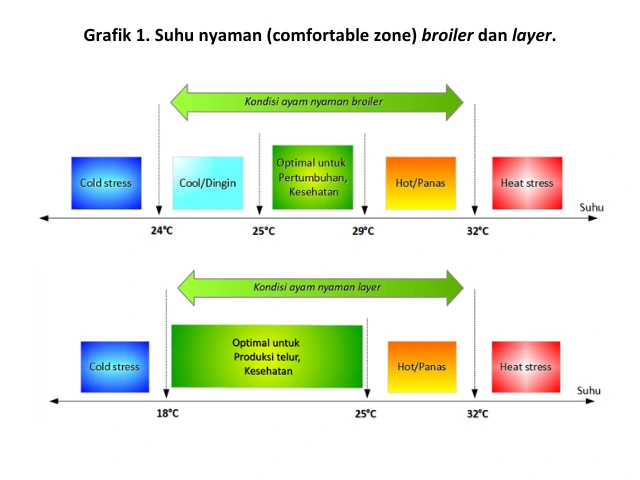

Based on data from BMKG in May 2025, several regions in Indonesia experienced extreme heat and moderate to heavy rainfall. Hot temperatures exceeding 36 °C were recorded in some areas, such as Deli Serdang (North Sumatra) at 37.1 °C. Moderate to heavy rain also occurred in regions like Kerinci (Jambi) with a rainfall intensity of 83.8 mm/day and the lowest temperature recorded at 17 °C. These conditions pose a challenge for poultry farmers, especially those raising broilers and layers, as they are highly sensitive to temperature and environmental changes. If left unaddressed, these conditions can cause chickens to become stressed, ultimately leading to decreased productivity.

A closed house is designed to control the microclimate inside the house (temperature, humidity, and airspeed) according to the chickens’ comfort conditions. The effective temperature (the temperature felt by the chickens) must be regulated to maintain their comfort zone. Chickens that are outside their comfort zone will experience disruptions in physiological functions. When chickens are cold, they try to warm themselves by huddling together, eating more to generate heat, and reducing activity. When chickens are too hot, they attempt to release heat by panting, drinking more water than eating, and in cases of extreme heat, may suffer sudden death. Therefore, proper management of the closed house system is essential to ensure its effective implementation.

There are several important factors to consider when facing extreme temperature conditions. These factors should not be overlooked, as they can be interrelated with one another. The following are key factors in managing extreme temperatures in a closed house system:

1. Ventilation System

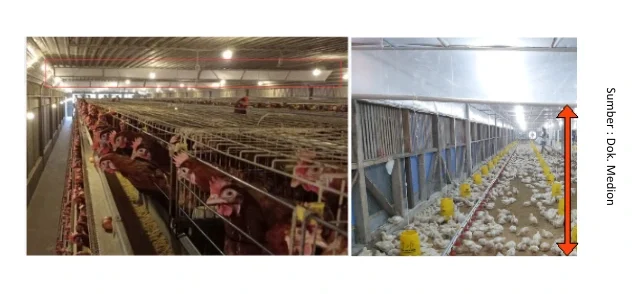

The ventilation system is a key component in both closed house layer and broiler farms. The ventilation system regulates the exchange of air inside the house with fresh air from outside. This air exchange is essential to meet oxygen requirements, remove toxic gases, regulate temperature and humidity, and create an effective temperature that matches the chickens’ comfort zone. The following are important factors in the ventilation system of a closed house:

a) Fan

Mechanical cooling using wind speed generated by fans must be carefully managed. The installed fan capacity greatly determines the resulting airspeed (wind speed). The airspeed requirement for layer production is around 2–2.5 m/s, while for broilers it ranges from 1.5–3.2 m/s. If the airspeed is lower than the target, chickens may experience heat stress, which can affect their productivity. Therefore, it is important to choose fan capacity that meets the desired airspeed target, such as the Multifan V-Plus 654 inch fan with a capacity of 58,700 m³/h, which can be adjusted using a variable fan system. This serves as a solution for both extremely cold and hot conditions, as the fan power can be adjusted to meet the minimum air requirement (in cold weather) or target temperature (in hot weather).

In addition to fan capacity, the number of installed fan units is also important to consider, as it affects the total airflow and airspeed produced. The number of fans should be adjusted according to the dimensions of the house. The house dimensions are calculated from the cross-sectional area, which is determined by the width and height of the house. If the cross-sectional area does not match the number of fans, deflectors/spoilers/baffles can be added to narrow the cross-sectional area so that the airspeed below the deflector meets the chickens’ requirements. The calculation for installing a spoiler is based on dividing the cross-sectional area by the width of the house. Routine fan maintenance—such as cleaning the shutters, checking shutter opening/closing mechanisms, tightening loose fan belts, and replacing worn pulleys—should be performed regularly to prevent any malfunction that could affect fan performance and, consequently, the microclimate inside the house.

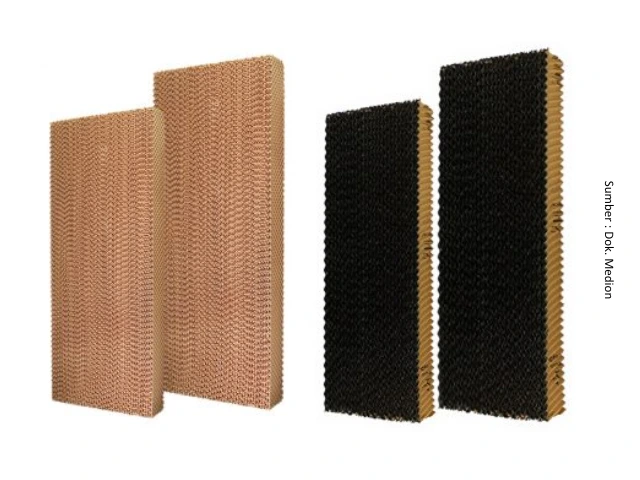

b) Cooling pad and sprinkle

The cooling pad is a cooling system that utilizes the evaporative effect. This evaporative cooling process is applied after mechanical cooling (through wind speed) has reached its maximum capacity. Once mechanical cooling is optimized, evaporative cooling can be carried out by operating the cooling pad system. The cooling pad system consists of several components, including cell pads, rain makers, pumps, and water reservoirs. This cooling system works by allowing water to flow through the cell pads so that the hot air entering the house passes through the wet surfaces of the pads, causing evaporation. As evaporation occurs, heat from the air is absorbed by the wet surface of the cell pads, resulting in cooler air entering the house.

When the outdoor temperature is extremely hot, the performance of the cooling pad becomes less effective in lowering the temperature. This reduced efficiency occurs because the incoming air is extremely hot and directly exposed to sunlight. One solution is to install a canopy so that the air entering the cooling pad becomes cooler and shaded. Regular cooling pad maintenance, such as low-pressure spraying and gentle brushing, is also necessary to prevent dirt buildup that can block airflow or affect the cooling pad’s performance. Dirt accumulation on the cell pad reduces the evaporative effect and decreases the airflow area, which negatively impacts the microclimate inside the poultry house.

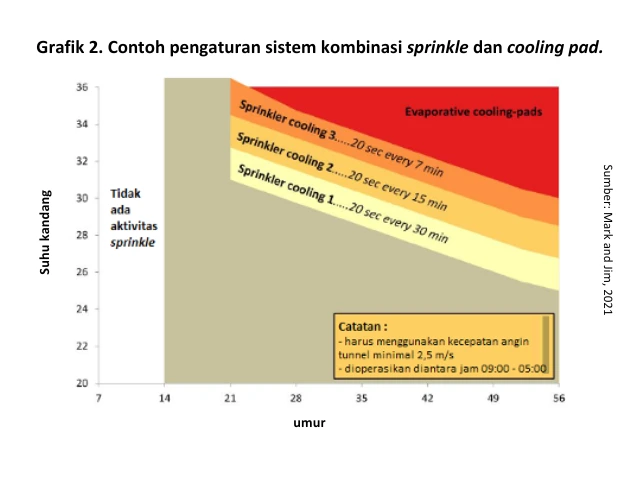

There is also a cooling method for poultry houses that uses a sprinkle system. The working principle of the sprinkle system is to spray fine water particles directly onto the chickens’ bodies. The sprinkle system helps reduce the load on the evaporative cooling process (as it can increase humidity) but cannot replace it entirely. The sprinkle system must ensure low water pressure, equal spacing between sprinklers, and operation through a controller based on a temperature setting (set-point). The use of a combination between sprinkle and cooling pad systems can be adjusted according to the house temperature. The sprinkle system can be operated between 09:00 a.m. and 05:00 p.m. The activation of the sprinkle and cooling pad systems can be managed according to house temperature conditions. The first stage of cooling should be mechanical, using airspeed from fans. Once this reaches maximum capacity, the sprinkle system can be used to wet the chickens directly. Under extremely hot conditions, the cooling pad system can be used to cool the house through evaporative effects. An example of a combination setup between sprinkle and cooling pad systems can be seen in Figure 2.

c) Balance Between Inlet and Outlet Areas

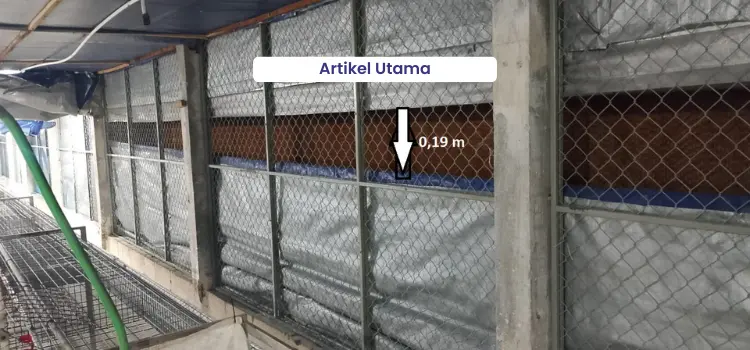

The inlet area is located near the cooling pad and is used to regulate the size of the air entry area based on the number of operating fans (on). The size of the inlet opening affects the amount of air entering, as it serves as the main entry point for air into the house. If the inlet area is opened too wide, the incoming airflow from the cooling pad will fall directly to the bottom or litter area, causing the litter to become damp and clumpy. Conversely, if the inlet opening is too narrow, airspeed will increase only in certain areas, leading to higher negative pressure inside the house. The determination of the inlet opening should be based on the number of fans that are on and the desired target airspeed. The size of the inlet area must always correspond to the number of operating fans. This is crucial because improper balance between inlet and outlet openings can result in uneven air temperature distribution or even create dead spots (areas with low or no airflow).

Example calculation of the inlet opening area:

Fan capacity: 42,000 m³/hour

In seconds: 11.66 m³/second

Target airspeed at the cell pad (type 45°/45°): 2.0 m/second

Total length of the cooling pad area (both sides): 30 m

Therefore, the inlet area is calculated as:

= Fan capacity / target airspeed

= 42,000 (m³/hour) / 2.0 (m/second) / 3,600 (seconds)

= 11.66 m³/second / 2.0 m/second

= 5.83 m²

Inlet opening size:

= Inlet area / total length of the cooling pad

= 5.83 m² / 30 m

= 0.19 m or 19 cm

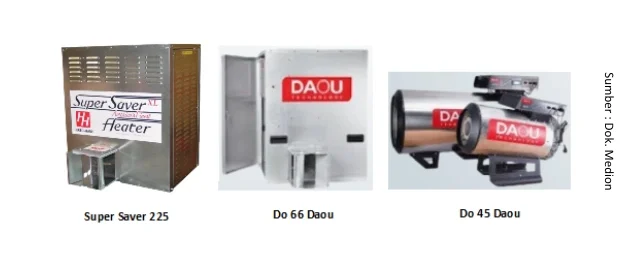

d) Heater

The key to maximizing chicken performance is providing a consistent house environment that meets their needs. Heaters should be checked and serviced before heating begins. Young chicks are still developing the ability to regulate their internal body temperature. Between 1–14 days of age, heaters (spot heaters or space heaters) serve as the main heat source in the house. Effective heating must consider the required number of heaters. For spot heaters such as the Medion Gas Brooder (IGM), each unit can accommodate 750–1,000 chicks per IGM. For space heaters, examples include Super Saver 225 and Do 66 Daou, which can heat up to 10,000 birds per unit. For medium-sized houses, the Do 45 Daou model can be used, with a capacity of 6,000 birds per unit. To prevent heat loss, blocking curtains inside the house should be used.

e) Adjustment of Blocking Curtain Opening and Closing

The opening and closing of blocking curtains are crucial during both extremely hot and cold conditions. The curtain adjustment should be based on the temperature. When the house temperature is hot or extremely hot—usually occurring at night—the curtains can be gradually lowered until they are fully opened. Farmers typically use one to four layers of blocking curtains. The lowering process starts from the back area (near the exhaust) and proceeds toward the front. When the temperature is cold or extremely cold, the curtains can be gradually closed, leaving a 10–20 cm gap to allow air exchange inside the house.

f) Emergency Alarm System

The emergency alarm system is used as a warning when issues arise that require immediate action. Emergency conditions may include ventilation system failure, electrical system malfunction within the house, or natural disasters (such as severe weather, floods, storms, or strong winds) that can damage the house and restrict the chickens’ access to feed and water. The alarm system should operate continuously to monitor the house environment, including temperature and power availability.

2. Drinking Water System

Chickens exposed to extremely hot temperatures tend to drink more water than they eat. During hot weather, water consumption can reach 2–3 times the amount of feed intake. Therefore, it is essential to meet the chickens’ drinking water needs by paying attention to the following points:

• Temperature

The temperature of drinking water affects chickens’ water intake. The ideal drinking water temperature for chickens ranges from 21–25 °C. Cover the top of the water tank to block direct sunlight. Wrap the tank with aluminum foil to reflect heat from the sun, and paint it white to further improve heat reflection.

• Nipple Line Leveling

An uneven nipple line affects water pressure at each point. Higher sections of the line may have lower pressure or even no water flow. A straight and level nipple line ensures uniform water distribution along the system, allowing chickens to meet their drinking water needs effectively.

• Nipple Leakage

Leakage in the nipple line reduces water pressure and can cause the manure or litter to become wet. Common causes of leakage include uneven nipple line height or excessive water pressure.

In terms of quality, during the rainy season with extremely cold temperatures, the quality of drinking water tends to decrease. When rain falls, surface water can carry various contaminants such as E. coli bacteria, which can make chickens sick and reduce their productivity. It is essential to regularly test the physical, chemical, and bacteriological quality of water at the Medion Laboratory. To improve water quality, a WTP (Water Treatment Plant) can be used. The WTP is an appropriate system for treating wastewater into water suitable for chicken consumption. In simple terms, the WTP process involves several stages, including filtration, coagulation, removal of harmful substances, sedimentation, and disinfection.

3. Manure/Litter System

During the dry season, manure can dry quickly—from 75% moisture content down to 20–30% within 3 to 4 days—with adequate airflow inside the house. However, during the rainy season, which is relatively cooler with lower wind speeds, manure moisture remains around 60–65% after 3 to 4 days in a layer closed house. An important factor to consider is the frequency of manure cleaning. When using an automatic system such as a manure belt or feces scrapper, cleaning can be done once a day. If using a manual manure system, cleaning should be done every 2–3 weeks or when ammonia odor starts to appear.

For broilers, good litter should be non-hazardous, have good water absorption, and be easy to obtain. The condition of the litter must always be monitored regularly. When inspecting the house, check the litter condition by walking barefoot or grabbing a handful of it. If the litter does not return to its original form after being squeezed, it indicates high moisture and clumping. When the litter is no longer suitable for use—such as when it becomes wet and clumpy—it should be treated by turning the rice husks over or replaced with new litter.

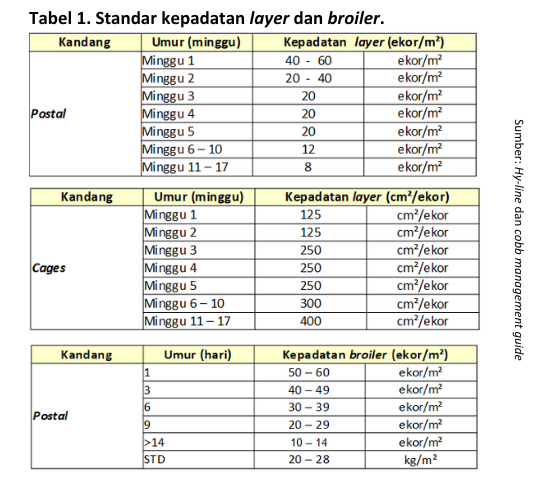

4. Chicken Stocking Density Management

Managing chicken density during extreme temperatures—both hot and cold—is crucial to maintain comfort, health, and productivity. Extreme temperatures can worsen stress, lower immunity, and increase mortality if not balanced with proper density management. The house density must be arranged so that each bird’s oxygen needs are met, for example, 18–20 kg/m² for hot regions and 20–28 kg/m² for cooler regions. High density can cause competition for oxygen intake and increase the risk of cannibalism within the flock. If the house becomes overcrowded, expansion or density reduction through thinning can be carried out according to standard density requirements. During extremely cold conditions, higher density can be maintained to help achieve a comfortable temperature more easily. The following are the standard density guidelines for layers and broilers based on their rearing age.

In extreme temperatures, whether hot or cold, it is essential to pay close attention to closed house management aspects such as ventilation, drinking water, manure/litter, and stocking density. With proper implementation, chicken comfort can be maintained, productivity can remain optimal, and disease risks can be minimized.