A vaccine is a microorganism that has been weakened or killed. Vaccines formulated in such a way are used as artificially controlled infections to stimulate the formation of immunity. One factor that plays an important role in the success of vaccination is the quality of the vaccine. A quality vaccine is expected to be one of the important factors so that the formation of chicken antibodies can achieve optimal.

A quality vaccine

Vaccine products marketed must be of good quality and meet applicable requirements. These requirements are regulated in the Indonesian Pharmacopoeia issued by an official body of the government of Indonesia. The Indonesian Pharmacopoeia contains standard information for the manufacture of vaccines in accordance with applicable requirements. In addition, exported vaccine products also need to meet international Pharmacopoeia standards.

Vaccines that have passed the test from the laboratory or vaccine manufacturer then need to be maintained in the hands of consumers. Methods of storage or handling (handling) vaccines from upstream to downstream are one of the keys to ensuring vaccines are safe and feasible to use.

Cold Chain System

The cold chain system is the process of maintaining the temperature of the vaccine in its ideal condition so that its quality is maintained from the beginning until the implementation of vaccination. Storage and transportation management must be considered to maintain quality (potency, safety etc.) from producers to the hands of breeders. In the case of patients who have been diagnosed with CKD (quality control), stored in cool room the vaccine has a temperature of 2-8°C. In addition to being available at the factory, this special room should also be available in the vaccine Marketing/distributor area. Vaccines are administered in cool room it is necessary to adjust its density and pile so that the circulation of cold air is evenly distributed. After from the manufacturer, the vaccine is distributed to the Marketing/distributor area using a special vaccine delivery car that has been equipped with a cooling machine so that the temperature is maintained at 2-8°C.

Vaccine Storage System

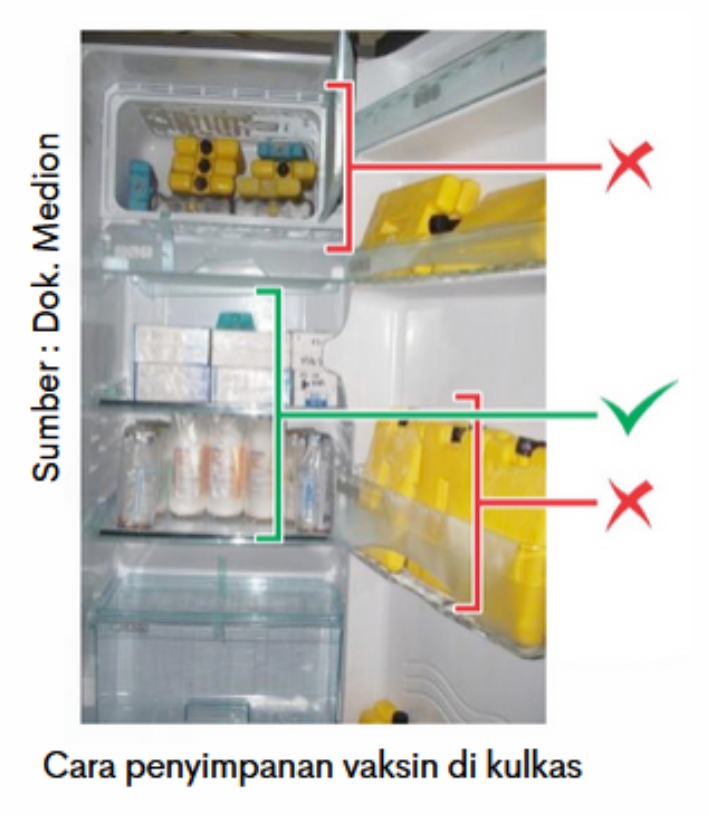

In addition to shipping, it is important to pay attention to handling when storing vaccines so that quality is maintained. Here's how to store vaccines, especially when they have been received by consumers, namely farmers, among others:

- Store the vaccine in the refrigerator at a temperature of 2-8°C.

- Storage in the refrigerator that is on the refrigerator, not on the freezer.

- Regular storage and spaced between packages for even air circulation.

- All types of inactivated vaccines are generally in liquid form, namely emulsions or suspensions. Do not store the vaccine at a temperature of less than 2°C, especially until it freezes. If it freezes, then you can be sure that the potency of the inactivated vaccine has dropped. This is due to the chemical structure adjuvant (carrier substance) the vaccine virus will be damaged at freezing temperatures. That means, the vaccine virus in it will also not be able to survive long if adjuvant- it's broken. To avoid this, the application of cold chain (cold chain) must be carried out by producers and vaccine users (farmers).

- The refrigerator should be set aside only for storing vaccines. Do not open the lid of the refrigerator too often so that the temperature in it remains stable.

- Do not store the vaccine on the refrigerator door. This is because the temperature is unstable and if often opened the lid will risk disturbing the stability of the vaccine.

- Do monitor refrigerator temperature regularly so that if there is a temperature mismatch will be detected from the beginning.

If there is a case of power outages, then over time the temperature of the refrigerator will increase. If the temperature of the vaccine is outside the range of 2-8°C, especially within more than 2 hours for active vaccines and more than 24 hours for inactivated vaccines, then the vaccine should not be used. Although the physical appearance of the vaccine has not changed, it is feared that the content of vaccine microorganisms has lost its potential and is not able to stimulate the formation of antibody titers optimally.

In conditions of power outages, one alternative that can be used in maintaining the temperature in the range of 2-8°C is to add ice cubes or ice pack. Especially when you don't have a generator. To make it easier in monitor the temperature, can be placed a room thermometer in the refrigerator to find out the real temperature so that the vaccine is maintained.

The technique of bringing the vaccine to the cage

When going to the cage, the vaccine can be put in marina cooler, cold box, or a thermos filled with ice cubes so that the vaccine is kept at a temperature of 2-8°C. There are several things to consider in carrying vaccines in general:

- The use of vaccines from the storage room must pay attention to the expiration date (FEFO, First Expired First Out) and vaccine entry sequence (FIFO, First In First Out).

- Check the condition of the vaccine when it will be used. Pay attention to the physical condition of the vaccine.

- When distribution and temporary storage, the temperature of the vaccine is always conditioned 2-8°C.

- Put the vaccine on the bottom of the marina cooler/cold box/ ice flask then give ice cubes/ice pack/thermafreeze around and on the vaccine. This is related to the spread of cold temperatures from top to bottom with a ratio of vaccine and ice cubes of about 50% : 50%. On inactivated vaccines should be given a partition between the ice cubes/ice pack with a bottle of vaccine so that the vaccine does not freeze. Do not carry the vaccine using a plastic bag because it is feared that it will not be able to keep the temperature stable at 2-8°C.

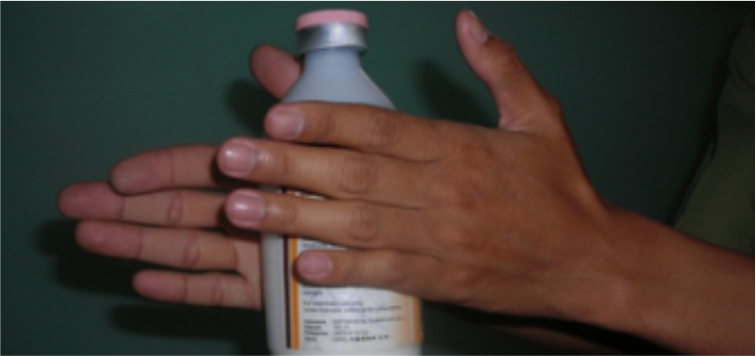

A good Thawing The right vaccine

One thing that is sometimes misunderstood when applying vaccinations is the assumption that when vaccination is done, the vaccine must still be conditioned by cold temperatures. Vaccines need to be made thawing in advance. Thawing or a gradual increase in vaccine temperature aims to condition the previous vaccine temperature of 2-8°C close to chicken body temperature or room temperature. This must be done to prevent chickens from being stressed by sudden changes in temperature, and so that the vaccine is easily absorbed in the chicken's body. Technique in doing thawing that is, the active vaccine is grasped and rubbed until the vaccine does not feel cold anymore. It can be characterized by the disappearance of dew that sticks to the vaccine bottle. While the active vaccine is done by mixing freeze-dried vaccine with vaccine solvent. Once in-thawingthe vaccine should no longer be used in marina cooler the temperature is 2-8°C because it can lower the potency of the vaccine. The active vaccine must be used up immediately within 2 hours while the inactivated vaccine is 24 hours.

The use of vaccines in livestock

When vaccinating, some things to consider are:

- Do not use the vaccine if the bottle is cracked or the seal is damaged and note the number batch vaccines and pay attention to their expiration date.

- The chicken to be vaccinated is in good health. If the chicken is infected with a disease, such as Coryza, then do the treatment first.

- The vaccination technique is carried out according to the recommendation (exact technique). If using a syringe, make sure the syringe used is sterile. Use an automatic syringe/Socorex which can be sterilized and reused. In injectable applications, the exact location of the injection becomes a critical point. When applying drops, pay attention to the accuracy of the dose given, namely one dose per tail and adjusted to the type of vaccine, for example, Gumboro active vaccine with oral drip application.

- In vaccination via drinking water, make sure the drinking water used to dissolve the vaccine is free of chlorine, disinfectants, or metals (iron, Ca, Mg, etc.) and has a neutral pH. This is because the quality of drinking water that is not suitable can interfere with the stability and quality of vaccines in drinking water. Add Medimilk 10g / 5L or Netrabil 5g / L of drinking water 30 minutes before the vaccine is dissolved to improve water quality, so that the vaccine's working power remains good during administration.

- Make sure each tail gets the same and uniform dose. Avoid rough treatment that causes stress or hasty chickens so as not to inject incorrectly. Make sure there are no chickens left unvaccinated and pay attention to the vaccine deadline after it is dissolved. When finished, make sure the chicken is doing its normal activities (back to eating and drinking).