The poultry floor is a part of the coop or a layer that covers the ground, allowing chickens to walk, rest, eat, and drink comfortably. It serves several main functions — absorbing manure, reducing disease risk, and improving bird comfort. Various materials can be used for flooring such as rice husks, straw, wood shavings, sawdust, sand, or alternative materials like plastic slat slats. Selecting the right floor material is crucial for maintaining chicken health and comfort since each type has its own advantages, disadvantages, and effects on productivity.

A. Type Flooring Litter

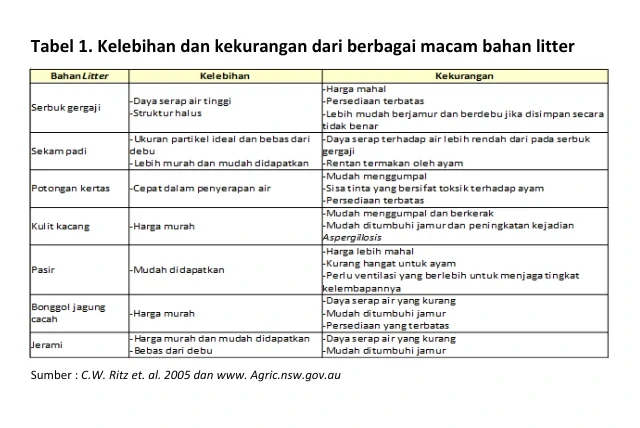

Litter serves to limit direct contact between the chicken's feet and the floor of the coop, maintaining temperature brooder stay warm and help absorb water from feces and spilled drinking water so that the cage floor does not become damp. Optimal control and management will help maintain litter in good condition. Selection of materials to be used as litter It must be precise, because if the litter does not function optimally, it will affect the performance of the chickens. Materials litter the most commonly used material is husk, because husk is easy to obtain and relatively inexpensive. The advantages of this material are litter which is in the form of husks, does not cause odor, has relatively medium-sized particles and is heavier, is the cheapest, is easily available, and husk waste that has been used as bedding can be resold for compost fertilizer. Meanwhile, the disadvantages of this material are litter husk has low water absorption or poor quality. If the husk is wet, it can cause respiratory diseases in chickens, and a larger amount is needed. Material litter it can also come from wood powder or sawdust, which has the advantage of high or good water absorption, a finer and denser structure, but also has disadvantages, namely the availability of materials that are sometimes hard to find, easily causes dust, and is prone to mold. Each material litter has its advantages and disadvantages.

When determining the type of litter to use, consider factors such as water absorption, availability of materials, economic value, and other impacts of the litter on the chickens. The use of rice husks is still recommended for raising chickens in postal-type coops. If rice husks are limited, other materials available in the area around the coop can be used, such as sawdust, straw, peanut shells, and others. Price of materials litter and transportation costs are taken into consideration in the selection of materials litter. In addition to price, availability of materials litter also taken into consideration. Many materials litter used in livestock farming but also needed by other industries such as manufacturing, fuel, fertilizer raw materials, and other industries.

1. Conditions Litter Perfect

Litter in chicken farming, it serves to maintain a comfortable environment inside the coop, such as absorbing moisture from feces, maintaining temperature, humidity, and ammonia gas levels. Material litter the ideal material is one that can absorb fecal matter and drinking water. Based on this absorption function, the condition is litter we must prepare dry feed for chicken maintenance. Litter the ideal conditions for chicken farming have several characteristics, including:

- Low moisture content

- Lightweight particles

- Medium particle size

- High water absorption

- Quick drying

- Soft and compactable texture

- Low thermal conductivity

- Inexpensive materials

- Abundant availability

- Usable as fertilizer

- Low humidity absorption from the air

2. Materials Litter

The following are various types of materials litter which can be used in chicken farming:

- Dried wood shavings or wood shavings from the wood processing industry are materials litter the best and considered the standard material litter pine shavings are the best for chicken coop maintenance, but the price and availability of materials are often a challenge. Shavings from hardwoods are generally not as good because there is a potential for hard splinters, mold growth, and high tannin content.

- Sawdust from the wood industry is an alternative to other materials if its moisture content is not excessive. Sawdust with high moisture content is prone to clumping and mold growth. Sawdust with particles that are too fine is not recommended due to the high dust content and the possibility that chickens will consume it.

- Material litter although rice husks have low absorbency, they can be used as a material. litter due to the abundant availability and low cost of materials.

- Material litter sand can also be used as a substitute for wood shavings, and is good for maintaining the quality of footwear and reducing the number of bacteria (Biligil, et al., 1999), but can increase dust and ammonia levels (Miles et al., 2011). Sand litter requires a slightly higher brooding temperature than other materials litter from wood shavings due to surface temperature litter on lower sands, especially in cold weather (Bowers et al., 2003).

3. Tips for Maintaining Moisture Litter

Practical ways to maintain your condition litter staying dry and maintaining low ammonia levels is a matter of prevention. The fact is that litter it has already started to clump together before increasing the fan settings. This can be considered a delayed response. It takes days or weeks of insufficient ventilation for moisture to build up to the point where litter started to clump together. After litter become damp, it usually requires an increase in fan settings to have a significant effect on litter moisture.

Steps that can be taken to maintain moisture litter excessive:

- Throw away litter clumping

- maintain the temperature of the cage

- Keep the fan running

- Prevent cage leaks

- Do pre-heating

- Ensure that the drinking water system settings are correct

- Use a circulation fan to move heat and humidity

- Check minimum ventilation

- Take advantage of the difference between day and night by removing moisture during the day.

- Be bold with the timer setting, make changes for at least 30 seconds.

Strategies for maintaining condition litter the ideal situation is to ensure that raw materials are always available and of high quality. litter good, as well as management litter to maintain ammonia levels at a safe level. Hazardous ammonia levels above 5 ppm can reduce chicken performance. Failure in management litter will incur significant costs to repair it.

Several important things to consider to help maintain and improve quality litter among others:

- Perform a reversal litter, addition litter, or replacement litter to reduce humidity litter previously. Reversals or additions are made if conditions litter the lower layer still has low moisture content. If conditions litter is very damp, so it must be replaced with litter the new one.

- Adjust drinking water equipment to prevent leaks. Make sure nipple, cup nipple, regulator, and the nipple pipe is in good condition before chick in.

- Ensure that the shape of the nipple and nipple cup suits the needs of the chickens. The 360-degree nipple model is the best model, and the appropriate water space is 10-12 chickens per nipple. If using a bell drinker model, the requirement is 10 bell drinkers per 1,000 chickens for a 40 cm diameter bell drinker.

- Check the condition and water pressure in the nipple daily to ensure proper use according to the age of the chicken. The water pressure in the nipple must be adjusted to the drinking water consumption at each age of maintenance.

- Feeders, waterers, heaters, and lights should be evenly distributed throughout the coop. Short distances between rows can cause chickens to not rest, and areas with high light intensity can cause chickens to migrate.

- The ratio between drinking water and feed. An increased water ratio can affect conditions. litter.

- The recommended litter material is wood shavings because it is the most effective at absorbing moisture.

- Dry the floor of the cage first before spreading the litter. litter untuk mencegah pembentukan kondensasi setelah litter ditebar.

- Thickness litter is 5-8 cm and should be evenly distributed throughout the pen when chick in with an ideal litter surface temperature of >30°C.

- Check the height line nipple. Height of line nipple the ideal position for a chicken's head when drinking is at a 45° angle. An angle that is too low will cause a lot of water to be wasted, so litter quickly becomes wet and damp.

- Check cup nipple every day. If you see water inside cup nipple, meaning the pressure is too high (nipple possibly leaking). If you see a few drops of water, then the height and pressure of the water in the nipple That's enough. If the nipple cup is dry, it means line nipple too high or the pressure is too low.

- Control the environment of the coop to optimize comfort and distribution of the chickens. Optimal comfort for chickens in hot climates can be achieved by using ventilation fans to create a cooling breeze (wind chill effect). Observe the chickens to determine their comfort level by looking at their panting rate and distribution. The comfort of the chickens will affect their water consumption in the coop.

- Usage cooling pad Evaporative coolers should not be operated at night because when the relative humidity of the incoming air is 100%, it will cause wet litter in the front area (around the inlet).

- Use Ammotrol as an ammonia level controller.

4. Impact Litter Damp

Litter Damp or wet conditions will cause several things that are very disruptive to chicken performance. The impact of these conditions litter among them are:

a. Clumped litter

High humidity causes litter clumping and covered by a layer of clumps, creating a layer that is constantly damp, sticky, and slippery. This is often seen in areas around nipple, on the side walls and corners. High humidity can cause the cage floor to become slippery. To prevent litter from clumping, humidity must be reduced through good ventilation circulation. If it starts to become damp, you can turn it over or add more litter just arrived replacement litter.

b. Cold temperatures

Litter wet litter cannot retain heat well, which can lower the body temperature of chickens and interfere with weight gain, feed conversion, foot condition, and immune function. Litter temperature is more important to chicken health than air temperature.

c. Source of disease

Litter moisture also triggers an increase in pathogens that can cause disease infections, as well as chest abrasions and dermatitis. footpad. If litter If the clots are not immediately removed and moisture is not maintained, it will cause lesions to form on the feet in the first week due to the presence of liquid ammonia on the surface litter that will erode the feet.

d. Formation of ammonia emissions

Litter If it is wet, it will cause health problems and decreased performance in chickens. Litter Wet litter will also cause difficulties in the removal or disposal process at the end of maintenance, resulting in suboptimal cage preparation. Moisture content litter The ideal level is around 20–35%. With such a low moisture content, the ammonia level produced is also low, i.e., <5 ppm. Ammonia (NH₃) is a gas produced from the decomposition of nitrogen residues from chicken feces. Protein from feed is digested and metabolized to produce waste substances in the form of urea and uric acid, which are excreted along with feces. Urea and uric acid contain nitrogen (N), which is converted into ammonia (NH₃ in gaseous form) or ammonium (NH₄⁺ dissolved in feces) by decomposing bacteria (ureolytic bacteria) in the environment. Moisture litter plays a role in the growth of decomposing bacteria, which indirectly affects ammonia levels (David et al., 2015). Ammonia is formed when uric acid reacts with moisture litter produces carbon dioxide and ammonia. Naseem and King (2018) systematically explain the chemical process of ammonia formation, namely C₅H₄N₄O₃ + 3[O]+ 4H₂O → 5CO₂ + 4NH₃.

5. The Effect of Ammonia on Chicken Performance

The negative impact of ammonia on chicken performance is weight loss. At ammonia levels of 25, 50, and 75 ppm, the weight loss is 2%, 17%, and 21%, respectively. According to Wang et al. (2011), three-week-old broiler chickens raised at an ammonia level of 0 ppm compared to 52 ppm showed a 5.3% increase in weight and a 2% lower mortality rate. Exposure to high concentrations of ammonia has a negative impact on the development of the chicken's immune system. The ability of chickens to respond to respiratory disease challenges is directly related to air quality. Ammonia can penetrate the respiratory defenses and allow pathogenic viruses and bacteria to enter the respiratory system.

Miles et al., 2011 concluded that the factors affecting the amount of ammonia produced from chicken manure are:

- Humidity litter high levels will increase ammonia emissions

- High temperatures cause greater ammonia emissions

- A water content of 46% will produce the maximum amount of ammonia.

High temperatures will also increase the amount of ammonia produced. At a temperature of 35°C and a water content of 20%, the increase in ammonia is about twice as much as at a temperature of 23.9°C. Each 5% increase in water content will result in a 3-4 times greater ammonia content under the same water content conditions. litter 25-30%. At a temperature of 35°C with a moisture content of 46%, this will result in the highest ammonia content. After the surface litter clump or layer, it will create a physical barrier that prevents the release of ammonia.

B. Cage Base Shape Slat

Alternative cage flooring can be in the form of slats made of wood, bamboo, or plastic. These slatted flooring materials are used as the base or floor of chicken coops. The function of this cage flooring is very important in producing performance optimal chicken. Cage base or slat has several functions, including:

- Maintaining the cleanliness and safety of the cage

- Providing a clean, dry, and comfortable environment for chickens

- Facilitates cleaning of dirt/feces

1. Slat Bamboo/Wood

Slat bamboo/wood is a poultry cage flooring material made from bamboo or wood that has been smoothed and designed to hold or support the entire population of chickens in the cage. With cage flooring in the shape of slat this way, the chickens will be cleaner and more comfortable because they will be separated from their waste, making them cleaner and reducing the negative impact of ammonia. The type of bamboo or wood used must be of good quality so that it is durable and long-lasting, because during the maintenance of these slatted chicken coops, they will be exposed to water droplets, feces, and feed residue. The selection of bamboo or wood types must also consider ease of cleaning. Cleanliness of slat this must also be maintained so that the chickens remain comfortable and their health is not compromised. During each maintenance period, the condition of the bamboo/wood slats must always be checked so that any damage or parts that need repair can be fixed immediately before the chicken maintenance period begins. Installation slat bamboo/wood, the distance between holes in each piece must also be considered slat. Slat holes that are too wide will cause mechanical injuries to the chickens and reduce their productivity.

2. Slat Plastic

Availability of litter which are increasingly limited and expensive, will become a problem in terms of material availability. In addition, slats made from bamboo/wood are easily damaged and relatively more difficult to clean, so there must be alternative materials that can be used as a substitute for flooring litter and also a substitute for slat bamboo/wood. Plastic slats are one type of cage flooring that can be used as a substitute for flooring. litterA good barn ventilation system can control humidity levels below slat. If humidity is high in the area under the slats, it will cause high ammonia levels and flies to appear underneath slat. The slat holes must be precise so that dirt can fall down. slat dan lubang slat also does not cause injuries to the feet and legs of chickens. Slat plastic can be the right choice for maintaining chicken performance and animal welfare.

Slat Medion Plastic is a cage flooring material made of high-quality plastic and specially designed for use in poultry farms. These plastic slats are made of PP material Copolymer. With standard dimensions of 100 cm x 50 cm and a total height of 20 cm, slat It has small holes measuring 1.5 cm x 1.7 cm.