Do you often come across feed raw materials with a high moisture content? Although it looks trivial, the high water content in feed raw materials correlates with the low nutrition of feed raw materials. In addition, the high water content also saves the risk of possible dangers, one of which is fungal growth.

The relationship of water content with the nutrition of feed raw materials

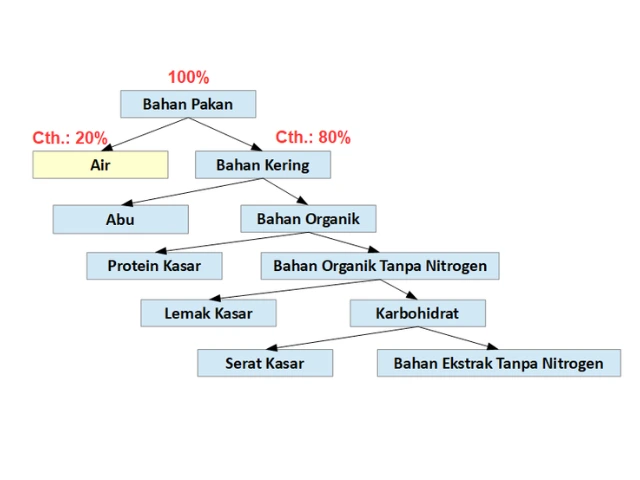

The water content is the percentage value of the water content contained in a material, usually expressed by the wet weight (wet basis) or dry weight (dry basis). Secara teoritis, maksimum kadar air dalam bahan baku pakan yaitu 100%. Standar kadar air bahan baku pakan yang baik untuk penyimpanan yaitu <15% namun dapat berbeda-beda tergantung jenis bahan baku pakan maupun kualitas dari bahan baku pakan itu sendiri. Sebagai contoh, Standar Nasional Indonesia (SNI) kadar air untuk jagung kualitas premium yaitu maksimal 14%.

Water content in feed raw materials in the field is closely related to various things, including :

1. Harvest time and season

Earlier harvest time (early harvest) and the rainy season will usually produce feed ingredients with higher moisture content. For example, early corn harvest water content can reach 20-40%. On the contrary, the corn we harvest is old, the water content tends to decrease. But it is usually followed by more fragile seeds, as well as damage to some micronutrients for example natural carotenoid pigments in corn.

2. Types of raw materials

Raw materials that have a high sugar content (example: starch polysaccharides) usually tend to easily experience increased water content. Because basically sugar is a substance hydrophilic (like water) hygroscopic (absorbs moisture). Instead of fat-based raw materials such as Crude Palm Oil (CPO) which is a substance hydrophobic (avoid water) has a low water content. Indonesian national standard (SNI) CPO water content is 0.5%.

3. Nutritional decline

High water content in percentiles can reduce the value of other nutrients contained in feed raw materials such as protein, carbohydrates, fats, etc. This is because water takes part in 100% of the feed raw material content.

If the feed raw material contains high water content, the nutritional value proportionally (defined in total dry matter) will be lower. Conversely, if the water content is low, then the feed raw materials will be more nutritious.

4. Long storage time

There is a negative correlation between water content and storage time. The higher the moisture content, the shorter the shelf life of the raw material. This is related to the properties of water that can damage the physical and chemical molecular structure of feed raw materials. Conversely, the lower the water content, the shelf life of feed raw materials will be longer and can last up to months.

5. Price

Feed raw materials with a lower moisture content usually have a higher price compared to feed raw materials that have a high moisture content. In the market of commodity goods such as corn, we often encounter in the field the price of corn with a moisture content of 17-18% cheaper than the moisture content of 14-15%. This is because low-moisture corn is considered more durable and nutritious. In addition, it could be because there are extra processes carried out by the seller such as Fanning, or baking so as to increase cost.

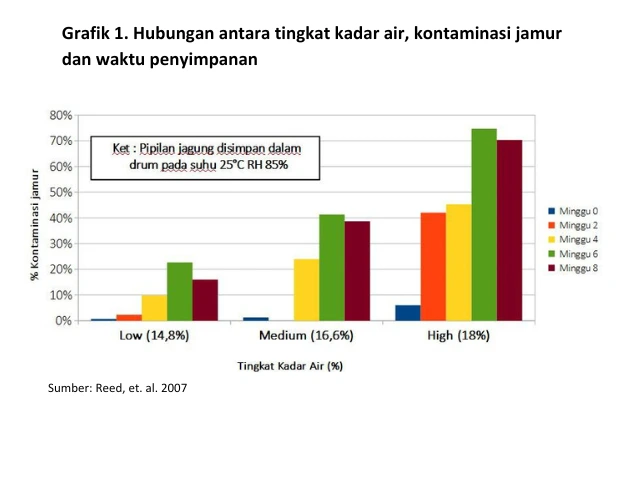

6. Risk of growing mushrooms

In addition to temperature, the high water content in the feedstock is ideal for growing mushrooms. Mushrooms can grow by absorbing nutrients that are in feed raw materials. Humid and warm conditions accelerate the growth of the fungus. So that usually feed raw materials that have been contaminated by fungi, the quality of nutritional value has been much reduced. Mushrooms can reduce the energy content by 5%, crude fat by 37-63% and protein by 6% to the initial nutritional value.

Another danger that can be caused by fungi is the production of mycotoxins. Mycotoxins are dangerous secondary metabolites that fungi can already produce within a few hours. One of the most common side effects of the drug is that it reduces the body's immune system (immunosuppressive). The presence of mycotoxins is the starting gate for bacteria and viruses to infect livestock. So it is not uncommon occurrence mycotoxicosis dipersamai with the emergence of the incidence of bacterial and viral diseases.

How to Prevent and Eradicate Them?

After knowing a brief explanation of the relationship of moisture content in feed raw materials and the real threat of the emergence and development of fungi, we need to determine the appropriate control measures. For that, some things can be done as follows :

* Choose supplier good raw material

The selection of raw materials begins with ensuring the storage time of the raw materials at the supplier. Make sure the raw materials are not too long in the warehouse supplier. In addition, farmers should also have several partners supplier so it can be a good comparison in price and quality.

* Do Quality Control raw material routine

Make sure every arrival of raw materials perform physical and chemical tests. Physical checking by touch whether it feels wet or even there has been a change in temperature (becoming hot). This indicates high humidity and fermentation activity, which is one of the signs of mold contamination. Always carry out other standard physical checks as well. For example, suppose in corn, check whether there are impurities such as COB crumbs, hollowed corn, etc. To remove contamination of corn cobs can use blower so that the corn cobs separate from the Corn Flakes. Also check the aroma and color of the seeds, whether they are rancid or have blackened due to mold or insects.

Also do a chemical examination, at least testing the water first usingGrain Moisture Analyzer the practical and portable. If moisture content >14% is found, it is recommended to carry out further testing of other nutrients, especially for farmers self mixing in determining the right feed formulation. Testing can be done at Medion Laboratories nearby.

* Do treatment drying

Treatment what can be done to reduce the moisture content of feed raw materials is by fanning or drying. Drying can be by drying in the sun or using a drying oven (eg.: Rotary dryer). Make sure the feed raw materials fanned or sun-dried are evenly exposed, not stacked on top of each other to avoid wet feed raw materials and even cause new problems.

* Use anti-fungal and antimycotoxins

The use of anti-fungal in feed raw materials that will be stored for a long time is mandatory for farmers. Fungi themselves cannot survive in an acidic/low pH atmosphere. So it is advisable to use an anti-fungal that can lower the pH. Examples Fungitox this is a list of the most common side effects associated with erectile dysfunction (mold inhibitor). Fungitox contains organic acid an acidic option, capable of inhibiting the growth rate of fungi in the feed. In addition, Fungitox also equipped with a toxin binder to bind mycotoxins already produced by fungi. Awarding Fungitox with a dose of 0.14-2.5 kg/ton of feed has been able to overcome concerns about the growth of fungi and the emergence of mycotoxins in stored feed ingredients.

In addition, we also need to carry out other controls in the internal cage to minimize the incidence of unwanted events, including by:

- Separating feed raw materials that have been moldy. If a small amount of moldy feed and want to keep it used then it can be mixed with feed that is still good, usually in the field using a ratio of 1 : 9 and must be directly given to farm animals.

- Add supplements such as MixPlus, Fortevit in order to memback–up micronutrient feed ingredients are certainly down and to increase the body's resistance to disease.

- Apply system inventory control feed raw material warehouse First in-First out (FIFO) and First expired-First out (FEFO). The raw material is the first to come and the Expiration Time is close, it must be used first.

- Pay attention to the condition of the storage shed, adequate ventilation, avoid direct sunlight or rain splashes. Use pallets in storing feed or medicinal raw materials and keep them at a distance of about 50 cm from the walls.

So, by understanding the relationship of moisture content in feed raw materials with nutritional value and possible risks, and seeing the control measures above, the best step is to prevent since the raw material is obtained, lower the water content level at the safe limit, and provide antifungal and antitoxin as a guarantee guarantee to maintain the quality of the material feed our cattle. May be useful.