Water is important for the chicken's body because it is the largest constituent component, which reaches 60-85% of all parts of its body. From this percentage we can know that water has a function and role that is so large and significant. Chickens are able to survive 15-20 days without rations, but without water 2-3 days can die. So the importance of water, then we need to pay attention to both the quality and quantity given to the chicken.

Drinking water consumption can be an indication of health or good/bad maintenance management practices. When the consumption of drinking water falls, then we must immediately evaluate the possible causes. Some of them are infected with diseases, the environmental conditions of the cage are too cold, the number and distribution of uneven drinking places, dirty chicken drinking places, poor water quality such as clarity and color of water, etc.

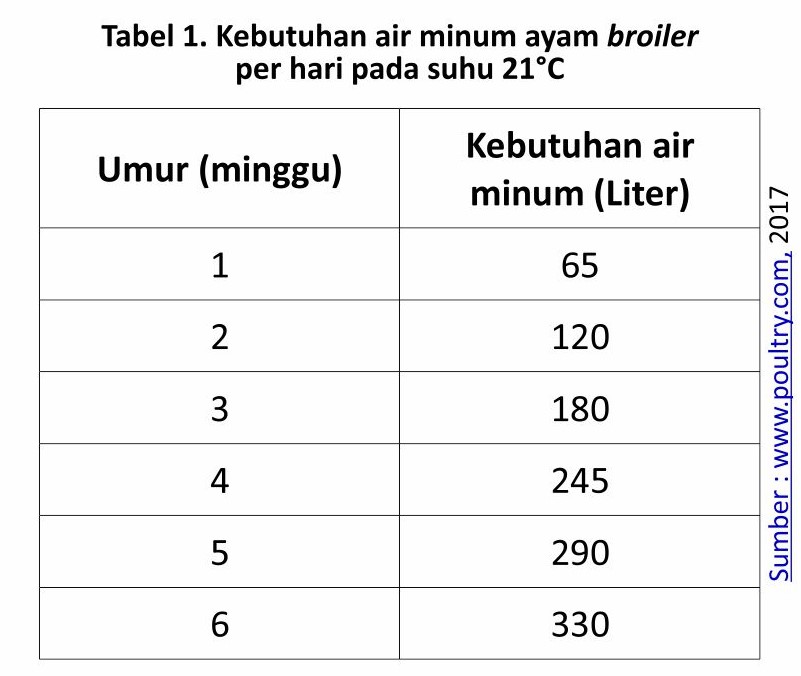

Drinking water consumption is closely related to ration consumption. At a temperature range of 21°C, chickens will drink 1.8-2 times more than they eat. This drinking water consumption will increase as environmental conditions change. Table 1 shows the drinking water needs of broiler chickens per 1,000 chickens at a temperature of 21°C.

Some factors that can affect the consumption of drinking water is the ambient temperature (drinking water consumption increased by 7% for each increase in temperature 1°C ambient temperature above 21°C ), the freshness of drinking water, water temperature (ideal 22-24°C), the ratio of drinking places and chicken populations, water quality and health status chicken.And ultimately it will affect the productivity of chickens. So the importance of water in supporting the achievement of chicken performance, then we need to pay attention to the quality of water given to chickens. Do not let the poor quality of drinking water cause chickens to drink a little.

Water that looks clear, could contain chemicals and harmful microorganisms. Not to mention the erratic seasonal changes in Indonesia, it is possible that water quality will change.The key, we as farmers must regularly check the quality of water in the farm.

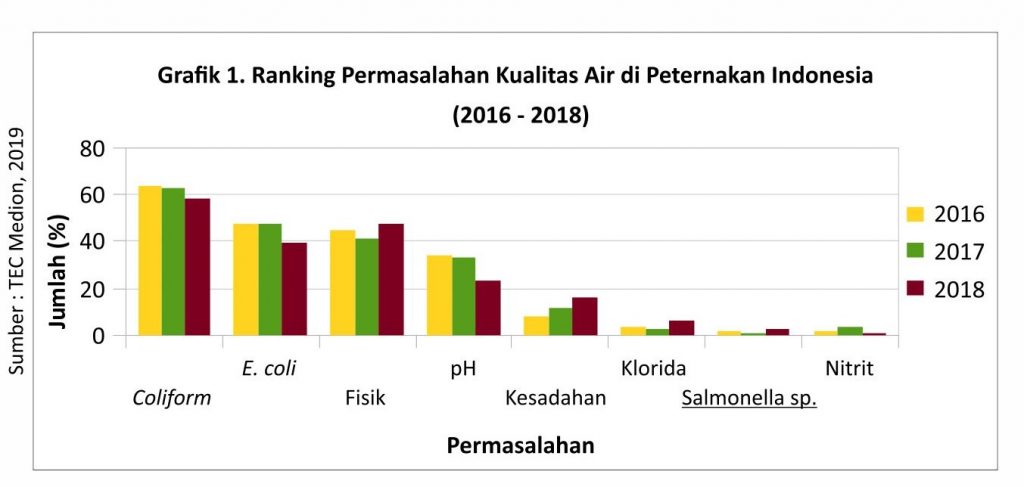

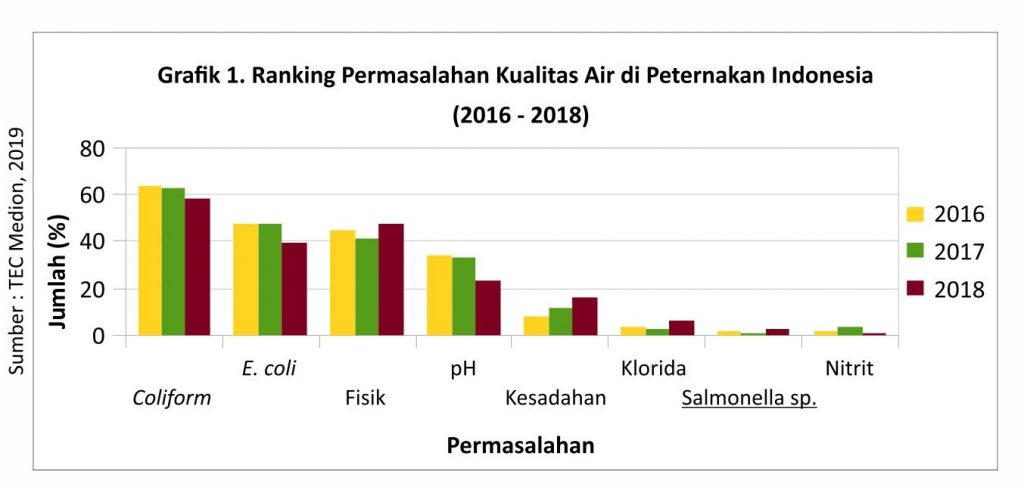

Refer to Team data Technical Education and Consultation (TEC)Medion (Graph 1) on the results of water quality tests in Indonesian farms for the last 3 years (2016-2018), it is known that more than 90% of water samples do not comply with applicable quality requirements. Of these 90%, the problem that dominates the problem of bacterial contamination of good bacteria contaminationcoliform andEscherichia coli. Furthermore, problems in terms of physical color, clarity and odor were ranked 3rd and continued by chemical problems in the form of pH that is too high or too low and hardness, chloride, and nitrite are not up to standard.

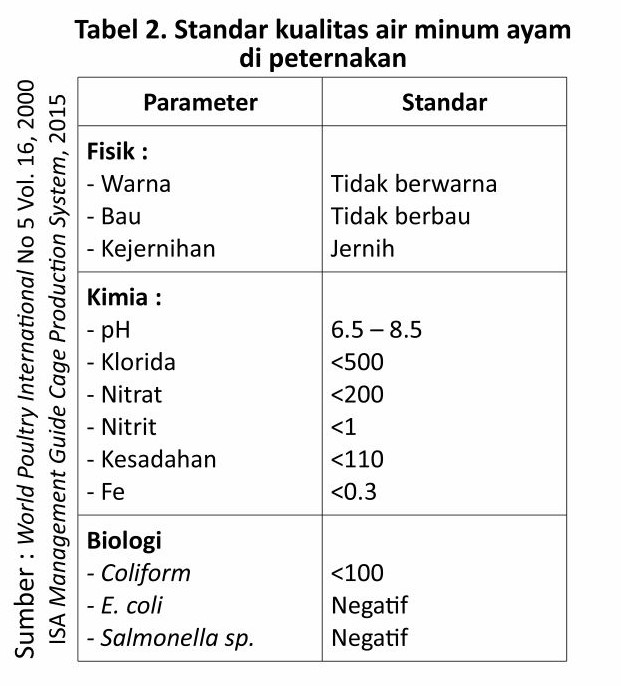

Water quality standards are measured through physical, chemical and biological parameters. Physical parameters include color, odor and water clarity. The chemical parameters of water include pH, chloride, nitrate and nitrite, hardness and iron content (Fe). While the biological parameters measured from the number and presence or absence of bacterial contamination coliform,E. Coli infection and Salmonella sp. The standard parameters can be seen in Table 2.

The chemical quality of drinking water that is not in accordance with the standards will affect the work of drugs, vaccines and disinfectants dissolved in drinking water. For example, in water that has a pH that does not match the standard will affect the stability of the active vaccine and hard water will bind the active compound in the antibiotic drugs of the fluoroquinolone and tetracycline groups so that it becomes ineffective again. As well as the high microbial contamination in drinking water will trigger the emergence of diseases such as colibacillosis and salmonellosis.

Achievement of chicken performance is strongly influenced by the quality and quantity of drinking water so that farmers need to maintain water quality as a whole, by :

1. Perform regular water quality tests

In order to handle water quality problems can be done properly, farmers must know in advance the quality of water on the farm. Moreover, water quality can change both in the rainy season and dry season (Scholar, 2016). Water quality checks should be carried out periodically, especially when there is a change of season, or at least once every 1 year (World PoultryVol. 25 No.3, 2009).

2. Treatmentwater according to the problem

After knowing the quality of water from laboratory test results, dotreatmentwater according to the problems that occur. If the problems that occur are complex, for example there are problems with the quality of physical, chemical and bacterial. Then it can be considered to create a system treatment modern water as in treatment refillable drinking water for human consumption, as an example of machine use filterto purify water, the installation of the system Reverse osmosis (RO) to minimize the content of metals/minerals and the use of UV lamps to kill bacteria E. Col.Treatment another that can be given is by giving Netrabil and Medimilk which can neutralize heavy metals and neutralize pH.

3. Clean equipment periodically

Drinking places that are dirty / rarely cleaned, will be a good place to breed bacteria coliform or E. Col. The number of these two bacteria is most widely contained in livestock drinking places. To prevent this from happening, clean the chicken drinking place at least 2 times a day, done by washing the chicken drinking place (TMA) before changing the chicken drinking water. The chicken coop (TMAO) by cleaning the dish TMAO using a clean cloth wipe dipped on Medisep. Periodically at least 1 Week, remove and clean filterwhich is on TMAO by the way in-flushing (spray with pressurized water) to remove deposits / mucus that may be present in filter TMAO.

Draintornwater and flushing water pipes for removal biofilm which is attached along the water installation channel. To be more optimal, use water cleaner/ hydrogen perioxide (H₂O₂)at a dose of 15-20 mg/liter of water or 10-15 ml/100 liters of water. How to dissolve water cleaner the water then flows along the water pipe. Let stand for at least 2-3 hours and then spray using high pressure clean water (www.edstrom.com).

Should flushing performed regularly at least 1 month. Because of the length of immersion H₂O₂, then specifically on farms that provide drinking water using a semi-automatic or automatic drinking system, the use ofh₂o₂ programit can only be done when the cage is empty. Or if not, can use other materials such as citric acid with a dose of 1.5-2 grams/liter, then allowed to stand for 1 hour (Tsai, 2003). But due to the formation biofilm also aggravated by the side effects of the administration of vitamins, drugs and vaccines, then flushing should still be done after the administration of drugs/vitamins / vaccines.

By looking at the data on the results of water quality tests on farms (Graph 1) and the importance of water for the achievement of chicken performance, it is time we realize that water quality needs to be considered well. Therefore, carry out regular water checks to prevent greater problems from arising on the farm. And pay more attention to the cleanliness of supporting equipment for chicken drinking water supply. In both cases, supported by treatment water according to the problems that occur hopefully our expectations in the maintenance and achievement of chicken performance can be realized.