The Target of raising laying hens in the production period is to reach the peak of production in accordance with the standards and the peak of production takes place over a relatively long period of time (good production persistence).

The resulting egg production must certainly be of quality and in optimal quantities so that it will get maximum profit. The quantity of production can be seen from the weight of eggs/egg mass the number of eggs produced/hen day. While the quality of Good Eggs that can be seen from the color, and thickness of the shellfish.

Peak production standards for Strain Isa Brown is 96.5% with production persistence >90% about 37 weeks (ISA Brown Cage Housing Product Guide, 2022). To reach the peak of production and the persistence of long production is required appropriate management starting from the period starter, grower up to layerso you're going to get chicken layer quality.

Laying hens that have not produced called pullet or a virgin chicken (age 0-16 weeks). Pullet the quality has characteristics such as the comb has grown and is red, the distance of the pubic os is 2-3 fingers, the distance of the sternum to the cloaca is about 3-4 fingers, the length shank/ bones of the lower leg about 10 cm.

The following are some of the factors that affect peak production and persistence of production include:

A. Human

Peak production and persistence of good production can be achieved if the cage manager really understands the management of laying hens and proper management of the cage. Starting from routine control of chicken conditions and cage conditions so that in case of deviation from performance can be repaired immediately.

B. Material

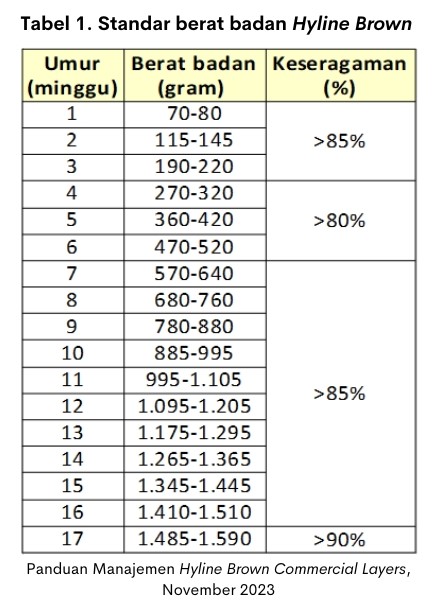

- Chicken quality pullet which will be maintained largely determine the success or performance from laying hens because pullet quality will result in optimal egg production. Pullet the good ones are pullet with standard suitable weight with high uniformity rate >85%. Weight standards and uniformity of chickens Strain Hyline Brown as in Table 1.

With good uniformity, the chicken will lay eggs simultaneously so that it reaches the peak of production and production persistence that can last a long time. Chicken pullet a good one will certainly turn out chicken layer which is good too so it will get peak production optimal and long production persistence.

Things to consider is the transfer or transfer of chickens from the cage pullet to the production cage. The displacement can cause stress against Chicken and chicken quality results pullet become decreased. Chicken quality pullet it can also be seen from the long shank 10 cm, fully grown Combs and red, and the distance os pubis 2-3 fingers.

- The ration given can also affect the amount of egg production, because the ration is the main source for chickens in producing eggs. The ration given must be of quality and given in the right amount.

- Seeds of diseases in the location of the cage will also affect performance from chicken layer modern, because if the seeds of the disease to infect chickens layer it results in impaired egg production either in quality or quantity of production.

C. Methods

- Implementation of appropriate health programs will result in quality pullet and chicken layer which is good so that it will produce optimally.

- Chicken selection or grading ayam total bisa dilakukan jika keseragaman sangat rendah <85%. Tujuan dari grading this is to classify chickens based on their weight, namely small, medium, and large. Each group is separated in the battery/cage the different ones are small chickens in the upper battery, medium chickens in the middle battery, and large chickens in the lower battery. After being separated based on body weight, different treatments are given, for example, small chickens are given additional rations while large chickens are not given additional rations so that it is hoped that later their weight will be equal and uniform.

D. Milieu/ environment

- Kondisi lingkungan yang tercipta di dalam kandang ayam akan membuat kondisi ayam nyaman atau tidak. Jika kondisi lingkungan kandang tidak sesuai dengan tingkat kenyamanaan ayam maka yang terjadi adalah produksi telur akan turun atau tidak sesuai standar. Kondisi lingkungan tersebut misalnya kadar amonia di dalam kandang yang dihasilkan dari reaksi penguraian feses dengan kelembapan sehingga terbentuk amonia. Amonia akan berdampak terhadap kondisi kesehatan saluran pernapasan ayam yaitu dapat merusak permukaan saluran pernapasan. Kadar amonia yang ideal <5 ppm.

- The health condition of modern layer chickens can also be caused by existing field challenges such as disease outbreaks around the farm location, poor environmental sanitation, and disease seeds around the location of the cage. The proper application of biosecurity can minimize the seeds of the disease into the body of chickens, namely by the principle of isolation, control of traffic of goods, people and vehicles that will enter the farm location and sanitation.

E. Machine

- Tools closed house among other fans. The equipment serves to create comfortable housing conditions in accordance with the needs of chickens. If there is damage to the machine it will interfere with performance chicken layer. For example, the cage becomes hot and humid due to a damaged fan or lack of specifications. Cage equipment closed house such as equipment ventilation system very instrumental in creating comfortable conditions for the cage. The ventilation system serves to circulate air, provide oxygen, remove harmful gases such as ammonia, carbon monoxide and carbon dioxide, remove moisture, and cool the temperature in the cage. If the ventilation system is impaired, it will have an impact on the effective temperature felt by the chicken so that the chicken becomes hotter.

- System lighting or lighting serves to provide light with the right intensity and duration for the development of chickens from the period starter until layer. In the period starter lighting serves to make chickens active and spread evenly, helps chickens in consuming rations and drinking water, helps in the process of forming growth hormone. While in the final period grower up to layer lighting serves to stimulate reproductive hormones and the process of egg formation. The Program of such lighting should be reproduction and the process of egg formation. The lighting Program must be appropriate both in intensity and duration because if excess or less will have an impact on adult sex more advanced or more backward in time.

Factors affecting peak and persistence of production in chickens layer which has been described above we should be able to control and prevent before fatal to egg production is to pay attention to the start of labor, quality pullet and chicken layer, proper health programs, perfectly functioning cage equipment, maintaining comfortable environmental conditions for chickens as well as the implementation of ration management and biosecurity right up to performance chicken modern layer will be optimal.