Along with the development of the Times, laying hens and broilers undergo genetic changes that are better in terms of performance and production. The existence of these changes requires an adequate supply of feed in terms of quality and quantity. This is contrary to the fact on the ground that there is still a downward trend in the quality of feed ingredients. Therefore, quality control of feed ingredients is very important. Quality control of feedstuffs can be carried out physically, chemically and microscopically. If the quality of the feed ingredients does not match the specifications, then the feed reformulation and supplementation steps become very important. Based on this, we will discuss some of the causes of the decline in the quality of raw materials, the important role of quality control and the importance of supplementation.

Modern laying and broiler chickens

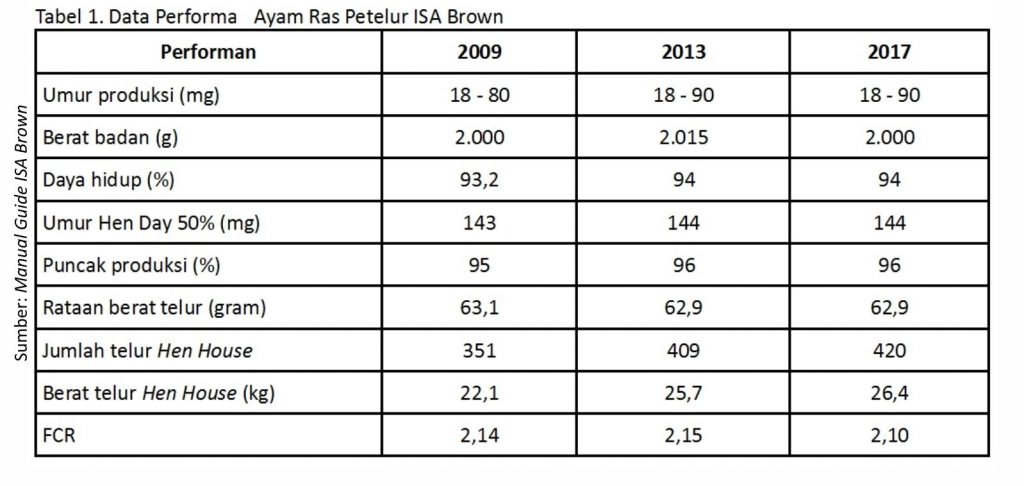

The performance of laying hens and broilers, in addition to genetic factors, is also influenced by nutritional, environmental and management factors. The genetic factors contained in all strains of laying hens both ISA Brown, Hisex Brown, Lohmann Brown, Hyline Brown and Novogen Brown have been formed in such a way that is capable of producing high egg production (henday) with a lower FCR. Likewise with broiler strains that are formed to produce high growth and meat production with a relatively short time. Behind these advantages, there are disadvantages that must be considered in their maintenance, namely, laying hens and broilers are more sensitive to changes in the environment and feed. This causes both chickens to be more susceptible to stress and even disease.

Chicken strains have their own properties and character during the maintenance period. Differences in these strains will also affect the nutritional needs.

Genetic quality improvement of laying hens and broilers today can be said to be spectacular in changing the feed they consume into eggs and meat. The logical consequence is that the growth and egg production of the chicken will depend on the treatment it receives, including feed treatment. Feeding that is changing because it is looking for a more economical price, can result in decreased egg production and meat growth that is not optimal.

Based on the table Manual Guide ISA Brown, high production with low FCR indicates that the chicken will be in demand to produce many eggs, with feed intake which remains low. This is because laying hens have a relatively small body weight with a slimmer posture.

Factors Of Deterioration In The Quality Of Feed Ingredients

Feed quality is very important to note because laying hens and broilers are very sensitive to the decline in feed quality, especially protein levels. The decrease in feed quality will be responded directly by broilers and layers with a decrease in growth rate and inhibition of egg production.

The factors that cause a decrease in the quality of feed ingredients include:

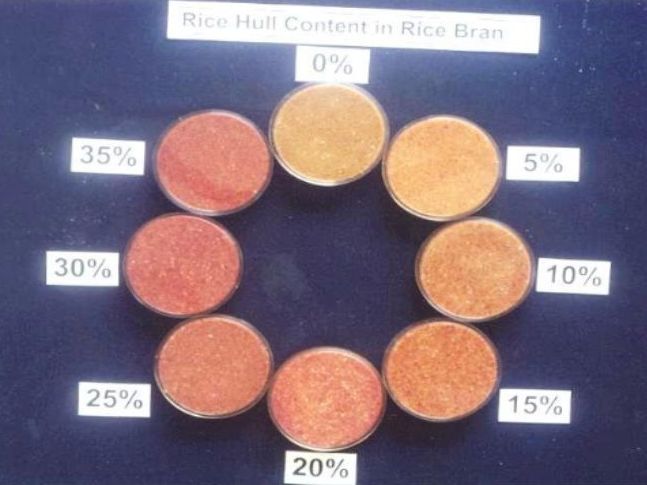

- High contamination. Contaminants in feed ingredients usually have a lower nutrient content or even do not have the nutrients needed at all by chickens. For example, contamination of the husk in Bran or Bran. To determine the presence of chaff contaminants in Bran or Bran can be determined by test Phloroglucinol.

- Storage. During storage, the feed will experience a decrease in the quality of nutrients, especially vitamins. So that feed supplementation is needed to replace lost nutrients, for example by adding premix.

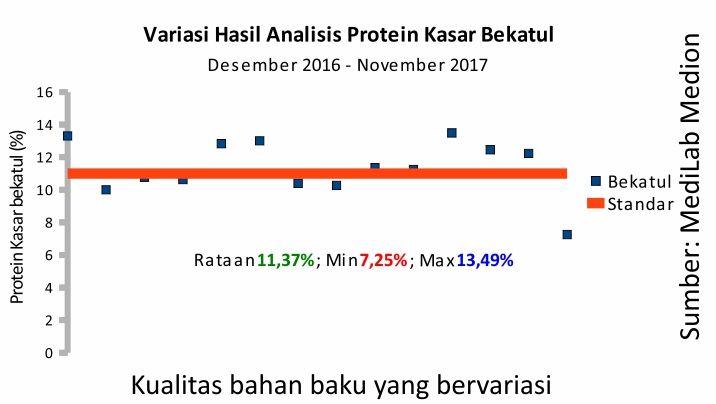

- Standard variety of feed ingredients. The variety of feed ingredients in the field is influenced by the age of harvest, seed type, soil fertility, fertilization patterns and contamination levels. Based on the analysis of crude protein content of Bran samples conducted in Medion Laboratory, obtained the results that there are variations in crude protein content of Bran from various sources.

- The high price of feedstuffs on the market. Farmers tend to look for relatively cheap feed ingredients. However, this tends to be inversely proportional to the quality of the feed ingredients. The farmer needs to find the optimal price, where the price is correlated with the content of nutrients in the raw material.

Importance Of Quality Control Of Feed Ingredients

Garbage in, garbage out a very suitable term to describe the importance of quality control of feed raw materials. The meaning of the term is that if the quality of the feed ingredients used is good and meets the standards, then the resulting feed mixture will be of good quality. As for the things that must be considered in the quality control of feed ingredients, namely when raw materials come to the farm, immediately record no. batch, name supplier, date, and amount of raw material load. After that, carry out a physical and chemical quality check (if necessary). After inspection, the next raw materials stored in the feed warehouse, and sorted by no. batch as well as the date of arrival.

Quality control of feed ingredients is carried out routinely when the feed ingredients come to the farm or when the feed ingredients have been stored in the warehouse. For perishable feedstuffs such as Bran, quality control is carried out once every 1 Week. As for feed ingredients that are not easily damaged, they can be done every 2 weeks.

Inspection of feed raw materials can be done physically, chemically and microscopically. Physically, feed raw materials can be observed with the naked eye, including color, odor, particle size, and fungal contaminants. While the chemical examination of raw materials can be done by proximate tests include water content, crude protein, crude fat, crude fiber, calcium, phosphorus, and gross energy. In addition, there is also a test Phloroglucinol to test for husk contaminants found in Bran or Bran. Microscopically, the type of raw material can be observed through a microscope with a magnification of 90-500 times.

Importance Of Supplementation

Quality control needs to be done regularly so that the quality of raw materials and feed is always optimal. It is also often necessary to do supplementation to keep the quality of raw materials and feed is always optimal so that chicken productivity remains optimal. Some of the factors that make supplementation necessary are :

- The amount of nutrients from feed raw materials is insufficient, especially micronutrients such as vitamins and micro-minerals. Although it is needed in less levels, but if it is deficient it will cause nutritional deficiencies and can reduce performance. To overcome this, it can be added premix for example, Mix Plus or Top Mix into the feed.

- Less than optimal handling and storage of feed. During storage, in addition to the reduced nutrient content, there is also the possibility of mold in the feed. If there is a fungus in the feed, then within 6 hours the fungus will secrete mycotoxins (fungal toxins). The growth of fungi is due to poor storage management, including moisture content > 14%, air circulation is not appropriate, high humidity and storage does not use pallet. To overcome this, it can be added binders mycotoxins or toxin binder, examples Freetox.

Feed Quality Control and supplementation are important to consider and apply. It is expected that the nutrients needed to support chicken productivity, both laying and broiler, are met so that chicken productivity remains optimal.