A breeder of laying hens in Blitar began raising since 2007 and always start maintenance with the preparation of a sufficient cage along with all the equipment. Every time the DOC came in, he did the appropriate selection of chickens and not according to the standard including weight selection done by weighing. It was then that he understood that at the beginning of the maintenance it was possible to get an idea of the good and not so good performance of chickens. So the selection and weighing of chicken weight from the beginning is very important.

The breeder routinely records until it reaches the phase pullet (16 weeks). From the results of the recording he could see the uniformity of the chickens raised. He found it interesting that at a glance there would be no difference, but after looking at the data, it turned out that significant differences in weight and growth were found. Farmers in Blitar realize that egg production is not only determined by the success of management and feed during the laying period. The growing period also largely determines the productivity of laying hens. It is in this regard that he emphasizes the importance of weight control and uniformity in the maintenance period pullet which will affect future production.

Pullet on the farm today

Many farmers complain that it is difficult to achieve the performance standards of laying hens even though they have done various kinds of business during the production period. Perhaps, this fact is due to the fact that there are still few breeders who pay more attention to management pullet in his farm or even do not understand about the importance of the phase. Sometimes maintenance efforts are only focused on improving nutrition and improving health programs, but this cannot be a solution if the quality pullet from the beginning it was low.

The population of laying hens has always increased from year to year, based on Animal Husbandry and Animal Health Statistics until 2016, the population of laying hens in Indonesia reached 161,349,806 heads while in 2015 it was still 155,007,388 heads. If the production age of laying hens reaches an average of 90 weeks, then the need pullet each week can reach 1,792,775 tail. This shows that the business opportunities of laying hens, especially pullet, is still very broad.

Pullet are laying hens reared at the age of 0-16 weeks. But usually it can be said pullet if it has entered the age of 12-16 weeks. Formation Program pullet the optimal one should start from DOC until the beginning of production. Pullet it has a wide range of body types (starter and grower). The human body (frame size) that are perfectly formed will greatly support the achievement of optimal peak production.

The Importance Of Understanding Uniformity Pullet

The optimal productivity of laying hens is influenced by many factors, one of which is the uniformity of chickens ranging from DOC to pullet or ready to produce. Good uniformity can be interpreted chickens in 1 population have in common. This condition is an important condition for egg production or henday can reach the top. As we already know, the level of productivity of laying hens is taken into account through a comparison between the amount of egg production produced in a particular population. So when the uniformity of the chicken is not optimal, the egg production time will be very diverse so that peak production is difficult to achieve.

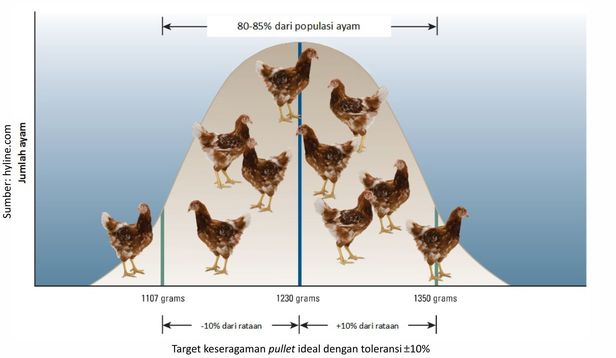

Uniformity becomes a measure of the variability of chickens in a population. Physically, the body weight of laying hens should be uniform. Uniform here would mean the weight of most chickens the same, that is, in accordance with the standard. The body weight of laying hens is said to be in accordance with the standard if it reaches + 10% of the target body weight of the standard maintenance guide for each strain. For example, the target weight of laying hens aged 12 weeks is 1,076 grams so that the body weight is said to be standard when the minimum is 968 grams and a maximum of 1,184 grams (Hyline Manual Guide, 2016).

It is better when the phase grower body weight can be at least equal to or exceed the target. Why? When chickens begin to produce eggs until the peak of production, called the critical period, usually experience stress due to egg production targets that must increase dramatically towards the peak, the weight or size of the eggs must increase and not miss the weight gain.

To achieve these targets requires more nutrients that are ready to use when nutrient intake is not optimal. And these” deposits " will be taken from such excess weight.

But the weight of the chicken is too large is also not an advantage. Weight that is too fat will cause fat deposits in the abdominal area (abdomen). This condition will reduce the elasticity of the oviduct because it is held back by the body's fat deposits. As a result, when there is a contraction of the oviduct, it is relatively difficult to return to its original position or there is a part of the oviduct that is outside. This condition will trigger the emergence of cases prolapse.

Uniformity is not only for body weight, but the uniformity of the size of the skeleton and the maturity of the sex also needs to be achieved because it will greatly affect the production and quality of eggs. The optimal size of the skeleton greatly affects the production and quality of eggs. During the process of egg formation, calcium in the body's skeleton will be taken to be deposited in egg shells. Once completed, the skeleton will be re-formulated with a supply of calcium and phosphorus from the ration. The small skeleton of the body will supply calcium in small quantities. This condition will cause the size of the egg to be relatively small. Whether or not the size of the frame (frame size) can be known from the length of the shank(Shin). At the age of 19 weeks, chickens layer it usually has a long shank 10.4 cm and the size will remain the same until the chicken is old.

Mature Sex

Sexual maturity (genital maturity) that occurs simultaneously is very necessary so that the peak of production is reached immediately and can last a long time. This sexual maturity must be adjusted to the maturity of the body (body weight).

When chickens are starting to produce eggs, we must immediately provide lighting stimulation so that egg production can take place simultaneously. Therefore, a chicken population with a good degree of uniformity, that is, at least 80-85% of chickens must have the same weight, body frame and maturity of the Sexes. Under these conditions, its maintenance management becomes relatively easy to implement, such as ration management, lighting and vaccination programs. The chicken's needs will be well met and the physiological response will also be the same. This condition is very necessary in order to achieve optimal egg production.

Weight control

Weight control (weighing) is important in the maintenance of laying hens and needs to be done regularly. The standard appropriate weight is an indicator of the status of the health condition pullet and as a determinant of production potential during the egg-laying period.

Poultry pullet those that are too light or too heavy of a standard will ultimately not be able to produce to their full potential. Some things to consider when doing weight control are :

- The number of chicken samples weighed 100 heads per cage evenly in each part of the cage and can be increased by 5% if kept in battery cages. The weighing method should also be per individual chicken.

- Weighing weight when laying hens age 0-4 weeks is done in groups while age > 4 weeks should be done per individual chicken.

- The scales used should be hanging scales with a dividing scale of no more than 20 grams.

- At the age of 0-18 weeks, weight control should be done every 1 Week, age 18 weeks until peak production is done every 2 weeks. After the peak of chicken production only need to be weighed once every 1 month.

- Weighing time is done at a fixed time, for example on Monday morning with the cache still empty, so it will be biased due to different times. Even if the weight of the ration consumed can be minimized, it is still different.

- After weighing, calculate the uniformity by comparing between chickens that fit the standard.

Target weight uniformity in one good FLOC is 80-85% for pullet, as for chickens, their production is already between 70-80%. Ideal uniformity occurs when 80-85% of the chicken population's body weight is in accordance with the standard, with a tolerance of ③ 10% of the target.

If there are two groups of chicken weight, one according to the standard and the other below the standard then do the examination and evaluation of the things that can cause low weight, such as the distribution of rations and drinking water and management of the beak is less appropriate. Another case if the uniformity is good but the average weight is below the standard. The handling is to check the quality and amount of rations given. In addition, also pay attention to the comfort of the cage (temperature, humidity and air circulation). Meanwhile, if the weight of the chicken is more than the standard, do the treatment to lose weight slowly and gradually. It is possible to reduce the amount of fluid (feed intake) by 2-5 g / Head / day gradually until weight is obtained according to the standard.

Factors affecting uniformity

Factors to consider in order to achieve uniformity include:

a. Quality DOC

A good DOC largely determines the growth of chickens in subsequent periods. Chicken uniformity will be achieved if the DOC is also uniform. DOC derived from various strains breeder also usually have different growths. Therefore, in a cage should be kept DOC of the same breed.

b. Cage Density

Cages that are too dense will increase competition in getting rations, drinking water and oxygen. This competition will bring up chickens that lose and win so that their growth becomes non-uniform. Density of laying hens during the period grower (4-10 weeks) preferably 12 heads/m2 (ISA Management Guide, 2015). Cage density should be regulated to minimize competition.

c. Place of ration and drinking water

Management of rations (feeding) which is not optimal can cause insufficient intake of nutrients that have an impact on the low level of uniformity. For example, if due to the late provision of rations, or the number and distribution of rations that do not match the number of chickens. The number and distribution of rations and drinking water places should be in accordance with the chicken population so that the supply of rations and drinking water is in accordance with the needs. In addition, the amount of feeding and the quality of rations and drinking water must be in accordance with the needs of chickens.

d. Comfortable cage

Chickens will grow and produce optimally if they are kept in comfortable cages. This comfort can be shown from the temperature (25-28°C) and humidity (70%) of the cage. In addition, air circulation must be considered so that it is able to bring out harmful gases, such as ammonia, CO2 and insert O2 optimally. Curtain opening and closing management needs to be applied appropriately. Additions exhaused fan/ fans can also be done to help air circulation in cages with low wind flow.

e. Cut The Beak

Beak cutting is able to increase the efficiency of the ration. If this is not done, or done but the results are not appropriate pieces, then the consumption of rations will still not be efficient and will actually affect the achievement of uniformity. This is because chickens prefer to choose a granular ration and a finer ration will not be eaten. Of course, this will harm the farmer materially due to the high cost of the ration that needs to be spent to achieve good performance and uniformity of chickens.

f. The Right Health Program

Diseases can lead to impaired growth and uniformity. Therefore, health programs must be implemented appropriately. Vaccination is carried out precisely both the schedule, the type of vaccine and the application of the vaccine. Likewise, treatment should be done appropriately. Biosecurity needs to be applied strictly so that the challenges of disease seeds can be minimized. So that the chicken will grow optimally until it reaches maximum production.

Obstacles that arise during maintenance Pullet and handling

Management during maintenance DOC to pullet this does tend to be complicated and requires more intensive attention aside from just paying attention to uniformity. In order for uniformity to be achieved even better, it needs to be supported by improved maintenance management such as choosing a quality DOC from the beginning, paying attention to the density of the cage, and creating comfortable air circulation conditions as previously described. However, there are still more obstacles that are often experienced during the maintenance period pullet as follows:

a. Less Than Optimal Brooding Period

Failure at this time will make it difficult to achieve optimal productivity in the production-ready phase. On time brooding period,, chickens will experience very rapid growth and include all organs that play a role in chicken productivity. Because a series of processes that occur during brooding period, so important, then the attention and intensive handling can not be missed at this time. Meet all the needs of the future brooding period, starting from the aspect chick guard, heater, litter, the availability of rations and drinking water, the need for temperature and humidity of the cage, air, and light.

b. Nutrition incompatible with the phase of keeping chickens

The content of nutrients in the ration is closely related to the stages of growth of chickens. Phase ration starter formulated to have a higher protein content than the phase grower and layer because needed for the period of growth. If this ration is given to future laying hens grower then the chicken will be overweight so that later egg production can not be optimal. While the ration for Phase layer it needs more nutrients such as protein, fat, metabolic energy as well as various minerals to optimize its egg production.

c. Lack of lighting control in the future grower

Lack of Phase period lighting control grower and chickens getting excessive light can result in two possibilities. First, the chicken will lay eggs early. Secondly, the weight of the chicken will exceed the standard due to the opportunity to eat at night, thereby increasing the likelihood of cases of prolapse. In this phase the light can be given in the shortest time (12 hours or only from sunlight) with the lowest intensity (5-10 lux).

d. Improper handling of moving cages

If the handling of moving cages is done too late and not right, the stress experienced by chickens is higher and results in egg production will be slow or even death. Catching should be done carefully at times such as night, morning or evening when the cage conditions are not hot. Try not to let the chicken fly too much and “scream”. Also use a quality and convenient means of transporting chickens such as Medion chicken baskets.

e. Lack of implementation of health programs

The implementation of health programs includes important components that affect the productivity of laying hens. The ideal is that the chickens have been vaccinated last a maximum of 2 weeks before production. Do it monitor antibody titer of ND, AI, EDS and IB routinely at least 1 month to see antibody titer Protectivity. Give supplements increase appetite and immune enhancers such as Kumavit. Kumavit contains active substances in the extract Curcuma extract which can accelerate the process of nutrient metabolism. As for adding minerals and other nutrients to the ration of laying hens, you can use Mineral Feed Suplement A. The use of Mineral Feed Supplement A will improve egg production and improve egg quality.

Uniformity has an important position on the level of chicken productivity. Uniformity control needs to be routinely carried out, including body weight, body skeleton size and adult gender. Greetings.