The term mycotoxin should be familiar enough to be heard in the ears of farmers. When mycotoxins are consumed by chickens, productivity will decrease, in the form of growth barriers, decreased egg production and even death. Not only that, these metabolites also act as immunosuppressants that can weaken the immune system to cause the body's response in the formation of antibodies from vaccination to be less than optimal. As a result, chickens become more easily infected with disease seeds.

Getting to know mycotoxins and Mycotoxicosis

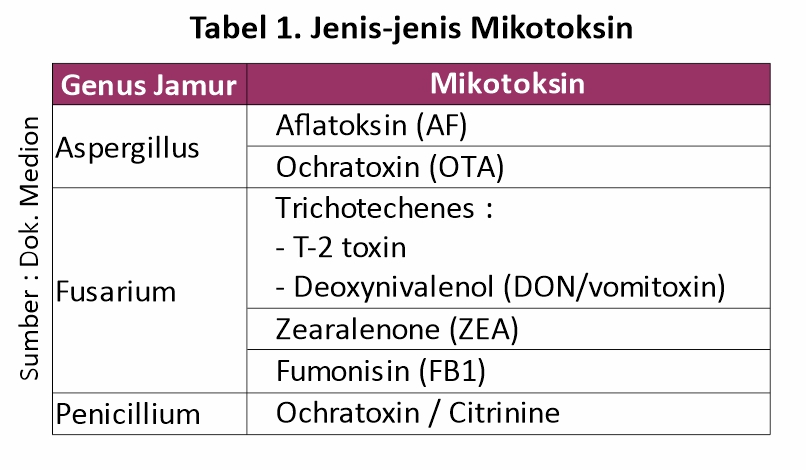

Mycotoxins are secondary metabolites resulting from the metabolism of certain mold/fungus species that grow on food and feed. Currently, 300 types of mycotoxins are known, five types of which attack many birds and are dangerous, namely aflatoxins, fusariotoxins (T-2, DON, zearalenon and fumonisin B1) and ochratoxins. Various kinds of mycotoxins are usually found in agricultural products (corn, bran, soybeans) with varying amounts/concentrations, ranging from part per billion (ppb) to part per million (ppm).

Mycotoxins are chemicals that are very stable and can survive for a long time even though the fungus that produces them has died. Even against heat treatment when processing feed, mycotoxins can in no way be degraded or destroyed.

Mycotoxicosis is a poisoning disease caused by mycotoxins. Mycotoxicosis attacks on chickens are influenced by several factors, namely sex, age, physical condition, nutritional status, levels and types of mycotoxins, feed consumption, duration of attack, and farm management.

Mechanism Of Contamination Of Fungi And Mycotoxins

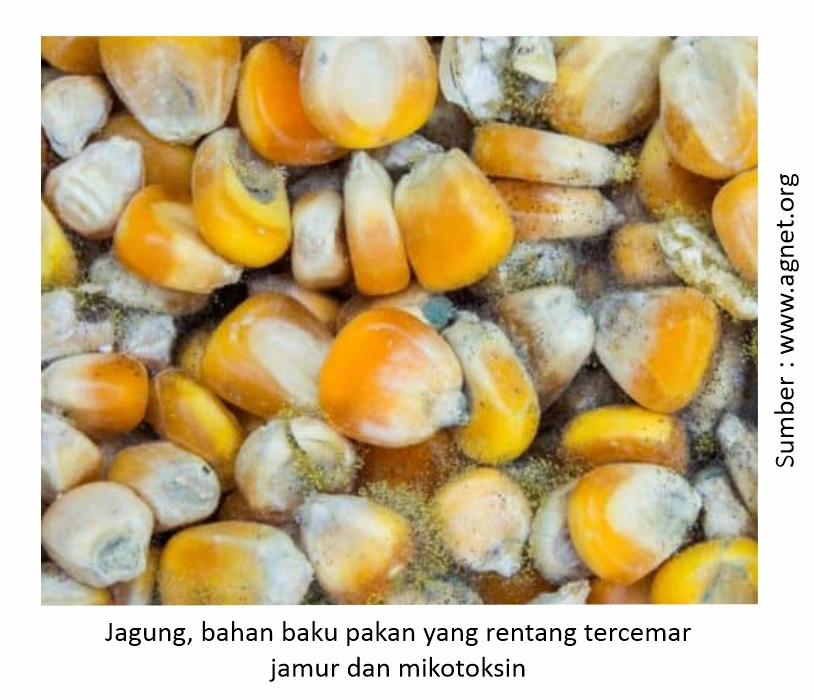

Corn seed raw materials are one of the ingredients that are often easily overgrown with fungi. This is because the energy in corn is in the form of starch which is mostly composed of amylopectin, and ovules which contain most of the oil (lipids). Almost all chicken farms use grains, especially corn, in their feed, thus all chicken farms have the same risk of experiencing cases of mycotoxicosis. Even so, the emergence of cases of mycotoxicosis depends on the optimization of feed management applied in each farm.

In addition to contaminating feed singly, several types of mycotoxins can simultaneously contaminate feed. The effects and dangers caused are more severe than with only one type of mycotoxin acting in the chicken's body. The presence of mycotoxins in feed is influenced by several factors, including:

1. Climate and global warming

Weather conditions during the harvest period to the storage of feedstuffs affect the increased incidence of mold and mycotoxin problems. In tropical countries such as Indonesia, mycotoxin contamination is very difficult to avoid because climatic conditions with high levels of humidity, rainfall and temperature are very supportive of the growth of mycotoxin-producing fungi. The secondary metabolite of this fungus grows and thrives at a temperature of 25-29°C and a relative humidity of 70%.

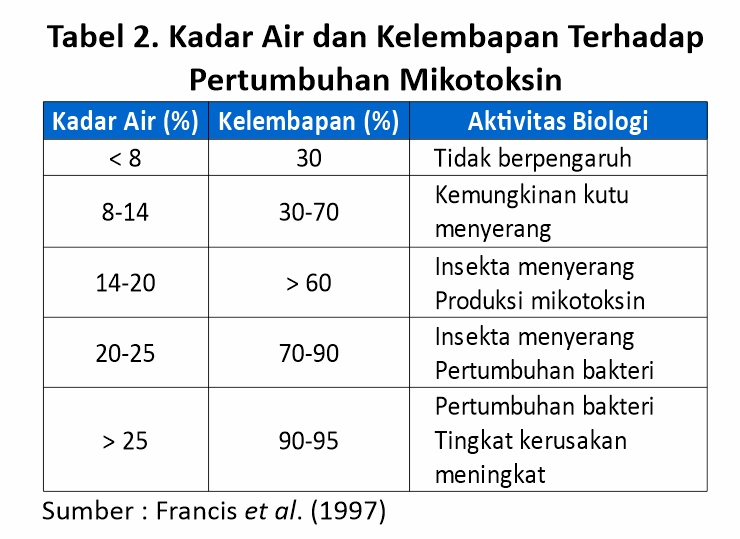

2. Water rate and humidity

Feedstuffs with a moisture content above 14%, especially raw materials that are hygroscopic, have the potential to grow mold.

3. Grain condition

Fungi (mycotoxins) are also affected by the number of servings broken seed (Broken Seeds), the condition of grain that has been damaged, either due to excessive heating, grinding or because it is damaged by insects. Fungi (mycotoxins) will be more and more when the seeds are broken and stored for a long time. In addition, poor storage conditions have the potential to cause contamination, resulting in decreased levels of feed nutrients. The shelf life of good chicken feed generally lasts for 21-30 days from the date of production (batch). While the storage of feed in a damp warehouse will certainly cause damaged feed within 2-3 days.

4. Conditions and duration of storage of feed

Errors in the storage of raw materials or feed in general such as insufficient ventilation in storage warehouses, and in damp places. In addition to the lack of use pallet under the pile of rations and visible rations attached to the wall. Although the moisture content of feed derived from the manufacturer or feed raw materials from supplier it meets the standards, does not guarantee that the feed to be given to chickens will remain of good quality if the storage is not right.

Case development and impact

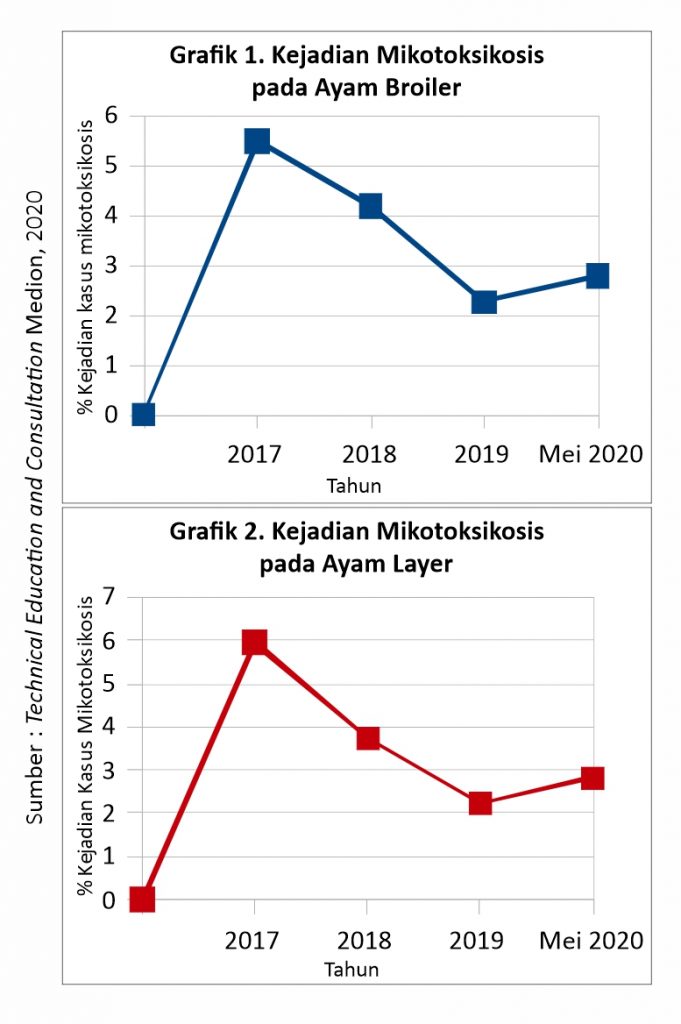

The case of mycotoxicosis is still one of the important cases in Indonesian livestock. How do mycotoxicosis cases progress from year to year? Here are the mycotoxicosis case data compiled by the team Technical Education and Consultation Medion in 2020. Graphs 1 and 2 show the percentage incidence of cases in chickens broiler and layer which varies each year. The decline in mycotoxicosis cases that occurred in 2019 can be expected to increase again if it is aggravated by extreme weather conditions that we cannot predict.

In the case of mycotoxicosis attacks, the effects of mycotoxins are sometimes not known by farmers for sure so that losses in terms of feed efficiency become quite large, for example, an increase in FCR values or a decrease in egg production that reaches 25-40%.

The effect of toxicity (poisoning) of mycotoxins depends on the intensity and time of intoxication (spread of toxins), and is accumulative. Broilers that consume feed contaminated with mycotoxins have shown stunted growth. Dersjant-Li et al., (2003) estimated that every 1 mg/kg increase in aflatoxin in feed would suppress broiler growth rates by 5%.

The same applies to laying hens. The presence of mycotoxin contamination will result in a decrease in egg production, both qualitatively and quantitatively. The quality of eggshell also decreases because aflatoxin will inhibit the conversion process of vitamin D3 contained in the feed into the active form, so it can not be used for the production of eggshells.

On the other hand, the presence of mycotoxins can also inhibit the absorption of amino acids, vitamins (especially Vitamins A, D, E, K), and minerals (Ca and P) in the digestive tract, and inhibit the synthesis of DNA/RNA proteins. At the top of the stairs (breeding farm), mycotoxin contamination can even decrease fertility because it causes testicular atrophy in reared Roosters.

As An Immunosuppressant

In addition to being able to reduce the productivity of chickens, mycotoxins are also known to have a major influence on the decline in the immune system (body defense) chicken or immunosuppressive. Immunosuppressive caused by mycotoxins is chronic, but if the concentration is high, it will be acute.

Further impact of this immunosuppressive effect is the increased mortality of chickens, chickens easily attacked by other diseases, as well as increasing the colonization of pathogenic bacteria in the digestive tract of chickens. Mycotoxicosis can trigger the occurrence of various diseases, such as Gumboro (IBD), malabsorption syndrome and fatty liver syndrome.

Recognize the types of mycotoxins and their symptoms

Here are some types of mycotoxins that often contaminate the ration and the symptoms and changes in anatomical pathology caused :

1. Aflatoxin

Aflatoxins are produced by fungi Aspergillus flavus, Aspergillus parasiticus and Penicillium puberulum. Aflatoxins are highly toxic and carcinogenic. This type of mushroom has good growing power in various places so that it is easier to contaminate feed raw materials, for example corn. Aflatoxin-producing fungi grow optimally and produce toxins at a temperature of 36.2-37.8°C with a relative humidity of 80-85%. The most toxic type is aflatoxin B1 which often contaminates corn, peanuts, cotton seeds, cereals, hay and vegetable oils.

Aflatoxin B1 has a primary hepatotoxic effect on various animals including chickens. Aflatoxin can interfere with the process of vitamin D metabolism, causing hair growth is inhibited, and bones become brittle. When the carcass surgery will be found pale liver and brittle, erosion occurs in gizzard (gizzard erotion/scab on the gizzard), bleeding in the thigh or chest muscles, swelling of the kidneys, enlargement of the kidneys and spleen, reduction/atopy of lymphoid tissue such as bursa Fabricius and tymus, and sometimes found blood spot blood on the eggs.

2. T2 Toxin

Mycotoxins classified in trichotesenes are produced by Fusarium graminearum, Fusarium sporotrichioides, Fusarium tricinctum, Calonectria sp., Gibberella sp., Trichoderma, Trichothecium dan Phomopsis. Temperature 6-24°C is the optimum conditions for the production of this mycotoxin. Diseases caused by T-2 toxins are called T-2 toxicosis.

The metabolism of the T-2 toxin mainly occurs in the liver and is the only type of toxin of the trichotesene group found in the liver. For cases of fungal infections Fusarium sp. it will be found the presence of ventricles or gizzard which has erosion. T2 toxin also causes lesions in the mouth of chickens (such as smallpox). In addition, damage by T2 toxin can lead to the death of lymphoid tissue and spinal cord.

3. Okratoxin

Octatoxin is produced by fungi Aspergillus ochraceus and Penicillium viridicatum. This toxin affects enzymes in the metabolism of phenylalanine, altering the mitochondrial transport system, inhibiting ATP as well as increasing the production of fatty peroxides, radicals and superoxides. Okratoxin accumulates in the kidneys, liver, muscles and fat and can affect the formation of meat. Ochratoxins can cause thymus atrophy, inhibit phagocytosis, and cause cell depletion of T and B lymphocytes.

To more precisely detect mycotoxin infection, it must be supported by testing feed samples, either through qualitative or quantitative methods. In qualitative methods, to detect the presence or absence of mycotoxins (especially aflatoxins) in raw materials such as corn, farmers can test using UV light.

To do this, the corn sample is first ground, then placed in a black box and highlighted with a UV flashlight. Corn that looks fluorescent (purplish green) indicates that the raw material already contains aflatoxin. In addition to the above-mentioned methods, the patient may also be able to test for the presence or absence of the tumor (MediLab) to find out what levels (ppm) of mycotoxins are present in it.

Preventive measures and how to deal with Mycotoxicosis

The large losses due to mycotoxin contamination make us realize that prevention efforts are important to do. Of course, the Prevention of mold growth is the most important first step that we must do.

Why? When the fungus grows on feed raw materials, it can be confirmed that mycotoxins have formed. What's more, eradicating mycotoxins requires treatment more, both physical, chemical and biological treatments, making it less efficient. It is different from the effort to get rid of mold, which is very easy, for example, by heating.

For this reason, some preventive measures that we can do are:

- Check the quality of feed raw materials regularly, especially when the arrival of raw materials. Try to keep the moisture content of raw materials or finished feed until 14%. If you already get raw materials with water content >14%, then immediately dry the feed ingredients by drying in the sun or using a special dryer, so that the water content drops. If the weather conditions do not allow also for drying, then carry out the arrangement of stocks and use such feed raw materials as soon as possible. If you need to add mold inhibitor, seperti asam propionat untuk menghambat pertumbuhan jamur. Jagung seharusnya disimpan pada kondisi tetap kering (kadar air <14%) untuk menghambat tumbuhnya jamur selama penyimpanan.

- Apply the storage system first in first out (FIFO: stored by date of arrival of feedstuffs) or first exipired first out (FEFO: stored by expiration date). So, prioritize older feed raw materials to use first. But if there is less good quality raw materials and does not allow it to be stored longer, it can be used first even if it has just arrived.

- We recommend that the construction of feed warehouses refers to the required cage construction procedures, such as sufficient ventilation, not in damp places, the position of the floor is higher than the ground level, and avoid dust.

- Use pallet under a pile of feed. Try that the feed does not stick to the walls. Leave a distance of at least 50 cm from the walls of the barn.

- Make sure the warehouse or feed storage area is not exposed to rainwater tampias, the air circulation system is smooth, and not damp. Avoid the activity of leaking feed with water to stimulate the appetite of chickens excessively because it can increase the risk of mold growth and mycotoxin production.

- Prevent contamination of fleas, rats and insects because it will damage the feed so that nutrient levels decrease and potentially spread disease

- Avoid repeated use of sacks or feed sacks.

- For breeders self mixing, increase machine cleaning period grinder or mixer, for example, once every 2-3 days. The rest of the feed, especially in the form of powder contained in both tools will be a source of fungal contamination in other feed raw materials.

- During storage of raw materials or feed, corn should be checked regularly and if identified there is a fungus that grows, immediately heat (>71-100°C) or dry the feed so that the fungus dies.

When fungi and mycotoxins have been found to contaminate feed, some things we can do to suppress the effects of these mycotoxins include:

- Selecting feed ingredients or feed by discarding those contaminated with fungi is very much.

- If the amount of feed contaminated with fungi is small, it can be mixed with raw materials or feed that has not been contaminated. However, it should be noted that this raw material should be immediately given to chickens so that the concentration of mycotoxins does not increase.

- Usage toxin (mycotoxin binder). Additions toxin being an effective solution to bind mycotoxins strongly while in the digestive tract, so that mycotoxins are not “active” and end up coming out together with feces (Galvano et al., 2001). Examples toxin which are widely used in the field because of their easy application and effective binding to mycotoxins are Freetox.

- There are no specific drugs for the treatment of mycotoxicosis. Vitamin supplementation high concentratevitamins, especially fat-soluble vitamins (A, D, E, and K), amino acids (methionine and penilalanin) as well as increasing the levels of protein and fat in the feed are able to suppress losses due to mycotoxins. Fortevit, Top Mix HC, or Mix Plus can be an alternative option.

- Give Gumbonal 1 g / L of water to drink for 3-5 days to reduce swelling symptoms.

- Administration of hepatoprotectors such as Heprofit it can also be done to improve liver function, considering that there have been organ changes in chicken liver.

Usage Toxin Binder

Usage toxin indeed, it becomes one of the effective methods to avoid the negative effects of mycotoxins on chickens. Working principle of toxin is that it binds mycotoxins in the digestive tract strongly, then excretes them along with feces.

In maintaining quality toxin already purchased, there are things that must be considered, among others:

a) dose of administration

Effectiveness toxin depends on the dose given. Each manufacturer toxin has carefully calculated how many grams of its use is most effective and efficient.

B) mixing way

Mixing toxin it must be done well so that it can be mixed homogeneously with feed raw materials or finished feed. If not done evenly, then the effectiveness toxin from each chicken will be different. In addition, you should also pay attention to the pH and temperature conditions when mixing, especially if mixed during the manufacturing process pellet or crumble.

C) storage

Toxin binder it should be stored in good conditions, in a dry place and have an optimal temperature. Ideally, a storage warehouse has a temperature of 20-25°C with a humidity of 60-70%. Storage should also use pallet as a base, and equipped with blower. Improper storage will reduce the quality toxin binder.

Additions Freetox being an effective and most widely used solution to bind mycotoxins (especially aflatoxins) so that they are not absorbed when in the digestive tract of chickens. Active ingredient in Freetox reported to be able to bind aflatoxins with the highest binding power. Freetox it is also able to bind 80% of the total aflatoxin contained in the feed, and bind it with more complex bonds. The bond is also known to be stable at pH 2, 7, and 10 and at temperatures of 25-37°C. When in the digestive tract of chickens, Freetox it will also not bind other nutrients (vitamins, minerals, amino acids) or drugs in the feed, so it is safe to use.

Untuk pakan dengan kadar air <14% dan kadar mikotoksinnya rendah, cukup campurkan 1-2 kg Freetox per 1 ton of feed. However, if the feed moisture content >14% and the mycotoxin content is medium/medium to high, then mix 3-5 kg Freetox with 1 ton of feed.

Mycotoxins are in fact able to reduce chicken productivity, even making chickens susceptible to disease (immunosuppressive). Therefore, it is appropriate that we should anticipate his presence. May be useful. Greetings.