Energy-source raw materials hold the largest proportion in feed formulations, such as corn and rice bran. The current use of corn in feed formulations is around +50%. The recent high price of corn has affected the final formulation cost. One effort made to reduce feed prices is substituting corn with other raw materials. The use of industrial by-products such as wafer/biscuit meal is starting to be considered as an alternative raw material to replace corn.

A. Getting to Know Wafer/Biscuit Waste

Wafer/biscuit waste is the by-product of wafer/biscuit production consisting of unsaleable products, crumbs left during packaging, or products that have exceeded their expiration date. The amount of waste produced varies; for example, one wafer producer with a production capacity of 26–30 tons/day generates 1.90–2.20 tons/day of wafer waste (Muarifah, 2009). In addition, the selling price of wafer/biscuit meal also varies between IDR 3,000–IDR 4,500 per kg.

More than 600 types of carotenoids have been identified in nature. Naturally, carotenoids are found in plants, animals, algae, fungi, and photosynthetic bacteria. These carotenoids can be synthesized de novo (synthesis of complex molecules from simple ones), except in animals. Animals cannot synthesize carotenoids, so the pigment colors present in their bodies are an accumulation of pigments from the feed they consume.

In general, the characteristics of wafer/biscuit waste depend on the composition of its raw ingredients, such as wheat flour, oil, sugar, water, salt, flavorings, etc. Wafer/biscuit waste with chocolate flavoring, for example, will have a color, smell, and taste resembling chocolate. Sometimes the presence of oil as a component of wafers/biscuits results in a slightly oily texture. The quality of wafer/biscuit waste also varies due to storage handling—for example, the presence or absence of mold. There are two forms of wafer/biscuit waste: chunks and meal/powder. Chunk form needs to be finely ground first to make mixing with other raw materials easier.

B. Nutrient Content of Wafer/Biscuit Waste

The nutrient content of raw materials will determine the nutritional targets of the formulation results, so it is very important to know the nutritional value of the raw materials to be used. The use of alternative raw materials must consider various requirements, including:

- Having adequate and balanced nutrient content

- Free of toxins

- High palatability

- Continuous availability

- Competitive price

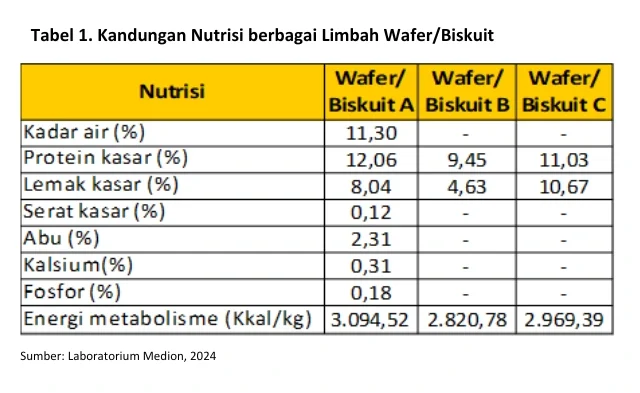

Table 1 shows the test results of 3 samples of different wafer/biscuit waste. Seeing the fact of nutrient variation and the absence of standard nutritional values for wafer/biscuit waste, it is crucial to know the nutritional value of the raw materials that will be used. In addition to physical/organoleptic quality control upon receipt of raw materials, chemical testing such as proximate analysis is necessary to determine nutrient values so that the formulated feed is more precise according to the needs of layer chickens.

High crude fat content elevates metabolizable energy. However, this needs attention because the higher the fat content in a raw material, the more prone it is to oxidation reactions, making the feed spoil more easily, including its nutritional value. A sign of oxidation is a rancid odor, which reduces the animal’s palatability (preference) for the feed. Preventive measures include keeping the storage warehouse in ideal conditions (25–32°C temperature and maximum 70% humidity). For raw materials with high crude fat, avoid storing them too long (maximum 21 days).

C. Usage Limits for Wafer/Biscuit Waste

The high metabolizable energy content in wafer/biscuit waste is an advantage as an alternative to corn. However, some field experiences show that using wafer/biscuit waste in high amounts to replace corn actually causes production problems. Some of the issues encountered include pale egg yolks and the presence of wet droppings.

1. Pale Egg Yolk

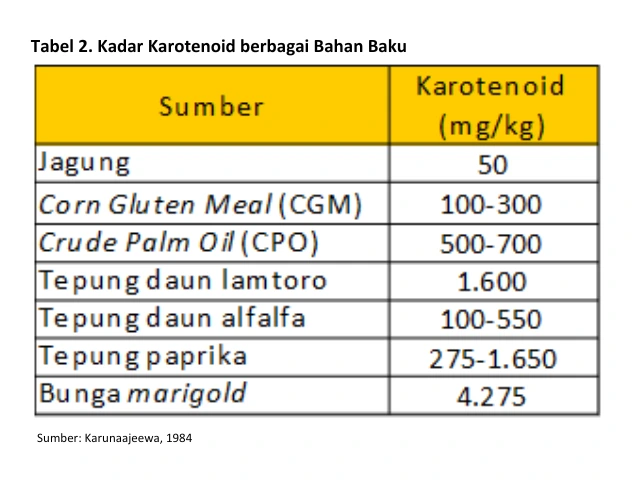

Egg yolk color is one parameter indicating egg quality. Indonesian consumers tend to prefer deeper, more reddish yolk color. The yellow color in egg yolks is produced by feed containing carotenoid pigments. Generally, the more yellow a plant-based raw material is, the higher its carotenoid content. Wafer/biscuit waste does not contain carotenoids because most of its composition comes from wheat flour, which does not contain carotenoid pigments. Therefore, when used in high amounts, it needs to be combined with other raw materials with high carotenoid content such as corn gluten meal In addition, adding synthetic pigments such as canthaxanthin contained in Mix Plus LLK8A can enhance yolk color.

2. Wet Droppings (Wet Dropping)

The occurrence of wet dropping is not only caused by disease and stress factors, but nutritional factors can also be the cause. Some nutritional parameters that cause wet dropping include excess crude protein, crude fiber, and salt content. Based on Medion Laboratory tests, the crude protein of wafer/biscuit waste varies between 9–12%, while crude fiber is relatively safe at around 0.12%; in Shahryar et al., (2012) the crude fiber test result was 2.55%. Salt content is a parameter that is rarely observed, but if excessive it can cause wet droppings. Based on Dewanto (2009), the salt content in biscuit waste is 1.032%. The standard salt level in layer feed is 0.31%. Excess salt increases water intake to balance body electrolytes, resulting in wet droppings. Salt content can be tested using the NaCl test method wet dropping lead to increased ammonia levels, making chickens prone to respiratory disease and reduced production.

Biscuit/wafer waste has potential as an alternative energy source raw material. However, its use needs to pay attention to usage limits to prevent declines in egg quantity and quality. The recommended use of biscuit/wafer waste is a maximum of 15% in the production-phase layer feed formulation.

D. Layer Feed Formulation with Wafer/Biscuit Waste

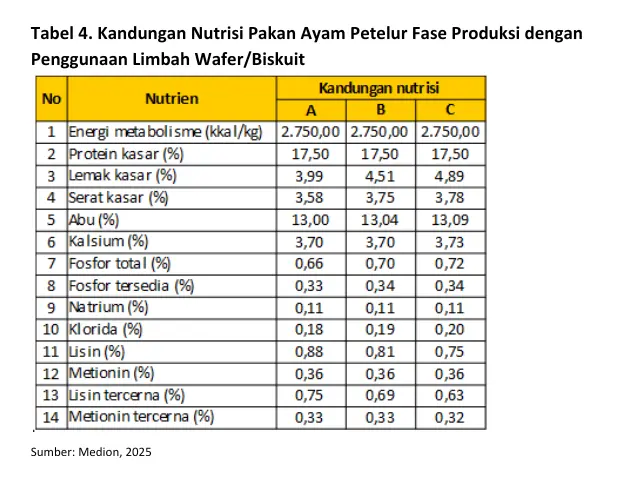

The high nutritional value of wafer/biscuit waste must be accompanied by high feed digestibility. The higher the feed’s digestibility, the more nutrients can be utilized by chickens. Conversely, if digestibility is low, nutrients cannot be utilized and are excreted with feces. Nutrients that are wasted not only pollute the environment but also cause economic losses for farmers. Therefore, when using alternative raw materials such as wafer/biscuit waste, it is recommended to add a multi-enzyme such as Prozyme at a dose of 0.75 kg/ton of feed to increase the digestibility of nutrients such as energy, protein, and phosphorus so they can be optimally utilized by chickens.

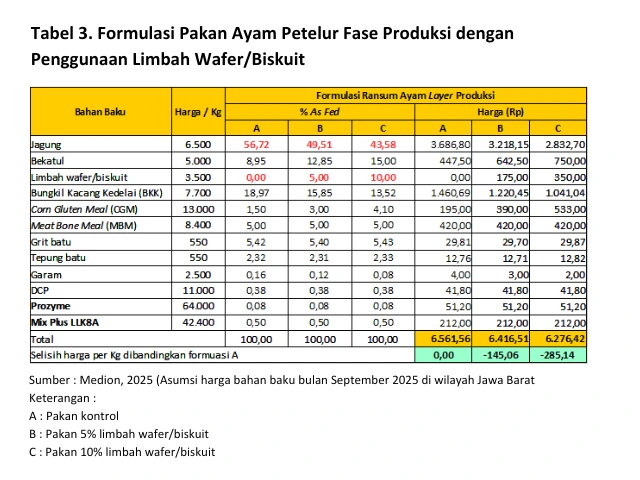

When using alternative raw materials like wafer/biscuit waste, if mold is present, separate the moldy parts so they do not enter the feed mix. As a precaution, Fungitox can be added to prevent mold growth and mycotoxins. Below is an example of a production-phase layer feed formulation with the addition of 5–10% wafer/biscuit waste (Table 3).

Based on formulation results using 5–10% wafer/biscuit waste, compared to the control feed, it can save IDR 100–200 per kg of feed. Thus, it can be used as an alternative when corn prices are high or corn availability is limited.

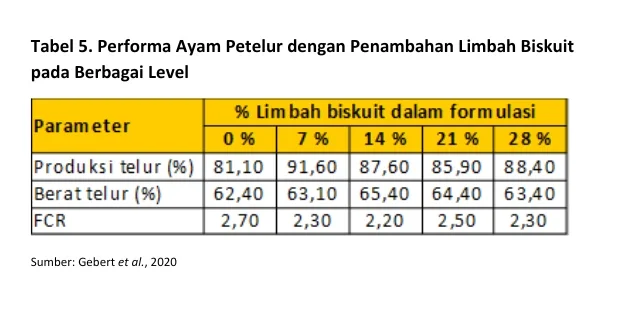

Research on the use of wafer/biscuit waste in layer diets is still rare; more studies have used wafer/biscuit waste as a corn substitute in broiler diets. A study by Gebert et al., (2020) on Hy-Line Brown layers strain Hy-Line Brown aged 48 weeks used five different inclusion levels. The biscuit waste used had 8.69% crude protein and 3,038.70 kcal/kg metabolizable energy.

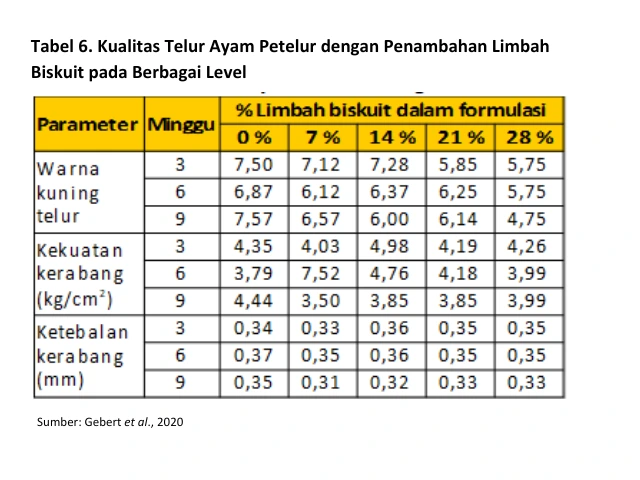

In addition to performance observations, egg internal and external quality were also observed at three different times: 3 weeks, 6 weeks, and 9 weeks.

According to Gebert et al., (2020), the addition of biscuit waste in layer feed is still feasible up to 18%. However, this limit depends on the variability of the wafer/biscuit waste used. In addition, the chickens’ response must also be monitored to avoid compromising health and egg production. The use of wafer/biscuit waste in layer feed should be done gradually, starting from 1%. Trials can be conducted on hens that have passed peak production. This is intended so that if production drops, losses can be minimized compared to using hens that have not yet reached peak production. Monitor and evaluate regularly until a safe inclusion level is obtained.

That is a brief overview of the use of wafer/biscuit waste in layer chicken feed. Hopefully it is useful and broadens our knowledge. Best regards.