The formation of the titer of chicken antibodies can reach the optimum if the vaccination is carried out correctly. One factor that plays an important role in the success of vaccination is the quality of the vaccine. Proper vaccine storage and handling procedures can affect vaccine quality. How to properly maintain the quality of the vaccine to keep it good?

Cold Chain System

Storage and transportation management must be considered to maintain the quality (potency, safety) of vaccines from the manufacturer to the hands of farmers. Cold chain system, vaccine management system according to procedures to keep vaccines stored at predetermined temperatures and conditions. The management process is applied during transportation,storage and handling of vaccines from producers to customers (farmers, Ed).

Oleh para produsen, vaksin yang telah lulus proses quality control (QC), disimpan dalam cool room khusus vaksin bersuhu2-8°C. In addition to being available at the factory, this special room is also available in the vaccine Marketing/distributor area. Vaccines prepared in cool rooms need to be adjusted in density and stack so that cold air circulation is spread evenly. After from the manufacturer, the vaccine is distributed to the Marketing/distributor area using a special vaccine delivery car that has been equipped with a cooling machine so that the temperature is maintained at 2-8°C.

Menghadapi Cold Chain Break

The quality of the vaccine will affect the success of vaccination. One that affects the quality of the vaccine is the procedure for handling the vaccine. All types of vaccines are unstable in hot weather (not thermostable) and will be damaged when exposed to direct sunlight for a period of time. For example, for inactivated types of vaccines, if the vaccine is stored at room temperature (30°C) for more than 24 hours, the potency will drop.

Namun meski vaksin pada umumnya tidak tahan terhadap panas, bukan berarti vaksin akan tetap bagus kondisinya jika disimpan pada suhu beku. Semua jenis vaksin inaktif, tidak boleh disimpan pada suhu <2°C (0°C [32°F] atau lebih dingin) apalagi sampai membeku. Jika membeku, bisa dipastikan potensi vaksin inaktif tersebut turun. Struktur kimia adjuvant (zat pembawa) virus vaksin akan rusak pada suhu beku. Itu artinya, virus vaksin di dalamnya juga tidak akan mampu bertahan lama jika adjuvant-nya rusak (WHO, 2006). Vaksin menjadi tidak dapat menginduksi respon imun tubuh ayam atau dengan kata lain perlindungan terhadap penyakit menjadi menurun. Tampilan vaksin belum tentu bisa menjadi indikator disimpan dalam kondisi sesuai atau tidak.Contohnya vaksin inaktif yang disimpan di suhu 0°C namun belum sampai menunjukkan perubahan menjadi beku.

Things to consider in vaccine storage

When going to vaccinate, some things that need to be considered by farmers are :

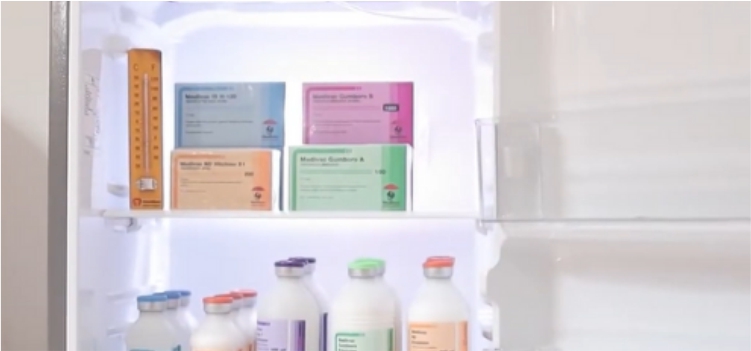

- When the farmer has purchased the vaccine, store the vaccine in a showcase / refrigerator set at a temperature of 2-8°C. Direkomendasikan memilih showcase khusus seperti refrigerator khusus untuk industri farmasi dan laboratorium atau refrigerator domestic “frost free”.

- Position the refrigerator not tightly against the wall or other items (such as shelves, cabinets) so that air circulation around it is smooth.

- The refrigerator should be set aside only for storing vaccines. Do not open the lid of the refrigerator too often so that the temperature in it remains stable.

- Avoid storing vaccines on the refrigerator door shelf because the temperature in that place is unstable as the refrigerator is opened and closed.

- Keep the room temperature at 25°C

- Attempted refrigerator electricity is not unplugged. Can by marking “do not unplug/ turn off” next to the switch / outlet and the power button.

- Perform routine refrigerator temperature monitoring so that refrigerator damage is detected early. Record such as maximum and minimum temperatures, temperature settings, room temperature and reading time at least 3x a day.

On the farm are often found cases of power outages that result in the death of the refrigerator. In such conditions, over time the temperature of the refrigerator will increase. As long as the refrigerator temperature is still in the interval of 2-8°C, this will not affect the quality of the vaccine. Therefore, when the power goes out and there is no electric generator (genset), then the alternative is that we can add some ice cubes so that the refrigerator temperature remains optimal for storing the vaccine. If the electricity is likely to turn on faster (

Handling of vaccines by farmers

When going to vaccinate, some things that need to be considered by farmers are :

- Pengeluaran vaksin dari ruang penyimpanan harus memperhatikan tanggal kedaluarsa (First Expired First Out, FEFO) dan urutan masuk vaksin (First In First Out, FIFO).

- Check the condition of the vaccine when it will be used.

- When distribution and temporary storage, the temperature of the vaccine is always conditioned 2-8°C.

- Place the vaccine in the center of the cooler box/ice thermos/filopur, then give ice cubes/ice packs/thermafreeze gel around and on top of the vaccine. The ratio of vaccine and Ice Cube is about 50% : 50%. Do not carry the vaccine in plastic because it is feared that the temperature in it does not reach 2-8°C.

- Sometimes during distribution and temporary storage, the temperature of the vaccine is not at 2-8°C which causes the vaccine to be damaged. Vaccines that are not carried using cooler boxes or ice flasks but with plastic or ordinary containers will not be able to maintain the vaccine temperature within 2-8°C.

- Do not use the vaccine if the bottle is cracked or the seal is broken and note the batch number of the vaccine and note the expiration date.

- Before giving to chickens, do not forget about the thawing process (increasing the temperature of the vaccine gradually from a temperature of 2-8°C to close to chicken body temperature/room temperature). The trick is to hold the vaccine until it doesn't feel cold anymore. If it is not done especially for inactivated vaccines correctly and the vaccine temperature is still cold, there will be a difference in the temperature range between the chicken's body and the vaccine temperature that is quite far. This can cause stress due to sudden changes in temperature and the vaccine is not completely absorbed in the chicken's body.

- One thing that also needs to be remembered during the vaccination process is that the vaccine does not need to be given ice cubes anymore. The vaccine does not need to be put in a cooler box with a temperature of 2-8°C because it can reduce the potency of the vaccine. Because temperature fluctuations can affect the stability of the virus / vaccine adjuvant. Inactivated vaccines should be given immediately after thawing and should be used for 24 hours.

- Chickens to be vaccinated must be in good health. If the chicken is infected with a disease, such as coryza attack, then do the treatment first.

- The vaccination technique performed must be precise. If using a syringe, make sure the syringe used is sterile. Use an automatic syringe/Socorex which can be sterilized and reused. In injectable applications, the exact location of the injection becomes a critical point. When applying drops, pay attention to the accuracy of the dose given, namely one dose per tail and adjusted to the type of vaccine, for example, Gumboro active vaccine with oral drip application.

- In vaccination via drinking water, make sure the drinking water used to dissolve the vaccine is free of chlorine, disinfectants, or metals (iron, Ca, Mg, etc.) and has a neutral pH. This is because the quality of drinking water that is not suitable can interfere with the stability and quality of vaccines in drinking water. Add Medimilk 10g / 5L or Netrabil 5g / L of drinking water 30 minutes before the vaccine is dissolved to improve water quality, so that the vaccine's working power remains good.

- Make sure each tail gets the same and uniform dose. Avoid rough treatment that causes stress or hasty chickens so as not to inject incorrectly. Make sure there are no chickens left unvaccinated and pay attention to the vaccine deadline after it is dissolved. When finished, make sure the chicken is doing its normal activities (back to eating and drinking).

Maintaining the quality of vaccines is not limited to storing them at cold temperatures and is only done at the manufacturer. Many critical points must be continuously controlled from upstream to downstream, meaning that from the time the vaccine is finished being produced until it reaches the hands of consumers.