The problem of cage odor cannot be underestimated, because it is one of the classic problems in poultry farming. The smell of the cage that lasts for a long time can cause disruption of the health and comfort of chickens and farmers as well as the emergence of pollution/air pollution to the environment around the cage. Ammonia itself production we can not avoid. High levels of ammonia can be triggered by substandard cage air circulation, overcrowded chicken populations, or poor management of cage bedding (husks) and feces. One thing is certain, the beginning of ammonia production comes from rations.

Ammonia Production Process

One of the constituents of chicken ration, which is a mixture of raw materials ration containing crude fiber3 gaseous form) or ammonium (NH4+ dissolved in feces) by decomposing bacteria (ureolytic bacteria) in the environment. Therefore, it is natural that in the maintenance of chicken livestock ammonia is produced.

Ammonia will also be increasingly produced if the process of nutrient metabolism in the body of chicken ration is less than optimal or excessive ration protein administration, so that not all nitrogen is absorbed as amino acids, but excreted through feces.

In the United States, the maximum ammonia level set by National Institute of Occupational Safety and Health (NIOSH) in the poultry house is 25 ppm, while by Occupational Safety and Health Administration (OSHA) is 50 ppm. In Indonesia itself, ammonia level measurement is still rarely done by farmers.

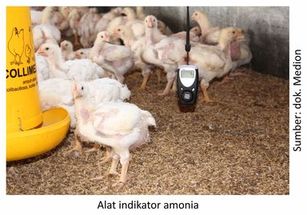

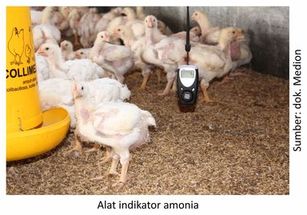

There are several ways that can be used to detect ammonia levels in cages, including by using an ammonia indicator device, namely an ammonia meter. The most important point when using such a device is to place it at the right height, for example, 10 cm from the floor or equivalent to the height of the chicken's head. If it is too close to the floor, the measured ammonia will be too concentrated, while if it is too high it will be less effective because ammonia tends to be carried by the wind/ambient air.

In addition, the easiest way that can be applied by farmers to determine the level of ammonia in the cage is the sense of smell. To make sure we detect the smell of ammonia, the farmer can sit squatting with his head close to the height of the chicken. Ammonia is a strong smelling gas. If the position smells of feces, then the ammonia level can be said to be excessive.

At high levels, ammonia can have a negative impact on the performance and immune system of chickens. Here's the explanation:

- Eye irritation disorderamonia will dissolve in the eye fluid and produce ammonium hydroxide (NH4OH), which are components of alkaline compounds capable of irritating and causing conjunctivitis (inflammation of the conjunctiva of the eye).

- Our sense of smell can detect and sense the smell of ammonia at a level of 5 ppm (low). But above this level, ammonia is already capable of causing mild irritation to the respiratory tract of chickens. And if the ammonia level has reached > 20 ppm, then ammonia will result siliostasis (stop the movement of the cilia) and desiliosis (ciliary damage) of the mucous membrane of the respiratory tract. As a result, ammonia with high levels can indirectly trigger cases of respiratory tract infections such as CRD, korisa, ND, AI, IB and ILT.

- Immune system disordersin addition to damaging the cilia, ammonia can also damage the epithelial cells of the upper respiratory tract so that the production of mucosal immunity (IgA) will decrease. Ammonia whose levels are very high can also enter the bloodstream (due to being sucked in large quantities) and cause stress on lymphocyte cells so that the production of antibodies (IgG and IgM) is impaired so that it affects the immune system and is susceptible to infection with disease.

- Disruption of egg productionaccording to Summers (1993), ammonia gas with levels > 30 ppm can result in alkalosis conditions (pH of body fluids, including blood plasma fluids are alkaline) in chickens. If the blood plasma is alkaline, then most of the plasma proteins will bind to blood calcium ions (which were previously free ions that will be stored in bone tissue and oviducts)oviduct)). As a result, the formation of bone/skeleton of the chicken body was disrupted and the resulting egg shells become thinner.

Suppress Ammonia Production

Farmers can suppress ammonia at the lowest possible level so that chicken productivity is not compromised. Some measures that can be implemented to reduce or reduce ammonia levels in the chicken coop, including:

- The first action that is important to do is not to give rations with excess protein content in chickens and ensure the metabolic process of ration nutrients (especially protein) runs well. One way that the metabolic process runs optimally is to reformulate (reformulate) the ration or add supplements Ammotrol through drinking water / ration. So it is with salt content. Salt levels that are too high in the ration will disrupt the electrolyte balance in the body so that chicken feces become wet. High salt levels will also trigger chickens to consume more water, causing chickens to experience diarrhea. Note again the use of raw materials rations with high levels of salt and protein such as fishmeal.

- Perform management litter that's good.

- It starts with choosing the material litter quality (dry, not dusty, able to absorb water optimally) as well as in sufficient quantities (not too thin).

- Use litter with optimal thickness, which is 8-12 cm for postal cages and 5-8 cm for stage cages.

- Perform flip-flops litter regularly every 3-4 days, from the age of 4 days to the age of 17 days. This is to avoid litter lumpy from the start.

- Repair the leaking roof of the cage as soon as possible and avoid hasty work, especially in replacing drinking water. Do not let water spill into litter. Install the drinking place installation correctly so that water leakage does not occur.

- If litter wet and lumpy in a small amount, immediately take out and replace with a new one. It should be sprinkled with lime in advance so that it dries quickly, after which it is simply stacked with litter the new one. However, if litter which clumps a lot, it is better to add litter new. Do not forget litter previously used substitutes are sprayed using disinfectants such as Medisep or Zaldes.

- Set the density of the cage set the density of the cage, where the ideal chicken density is 15 kg/m2 or the equivalent of 6-8 broilers and 12-14 laying hens grower (pullet) per m2 her. When the beginning (period brooding period,) do regular widening of the cage bulkhead according to the growth of the chicken until the entire cage is occupied.

- Pay attention to air circulation by paying attention to curtain opening and closing management, adjusting the distance between cages, and increasing use blower or fan (fan).

- Do the proper management of handling feces under the cage for the stage cage so that the chicken feces are not damp and the formation of ammonia is inhibited.

From the entire discussion above, we can conclude that air quality greatly affects the environmental conditions around the cage and disrupts the comfort of life for both chickens or farmers in the cage. If the air quality is good, then the chicken can grow and produce well. And vice versa. Therefore, farmers are obliged to reduce the concentration of ammonia gas, which can reduce this quality. One way is to use Ammotrol. Ammotrol safe to use daily for long periods of time to bind ammonia without causing side effects and residue. Awarding Ammotrol also relatively easy, simply sprayed into feces or dissolved in drinking water, and can be given together/mixed with vitamins or antibiotics. May be useful.