The problem of fungus is not only experienced by humans. The fungus also attacked commercial chickens on farms. The impact of losses that will be experienced by farmers is not small. Mold cases also do not only occur during the rainy season. During the dry season, this case can be found, especially as it is currently categorized as wet drought (dry season that is still accompanied by rain). Therefore, we need to be aware of this problem. Control of fungal contamination through early detection with visual inspection on rations and raw materials rations, the addition mold inhibitor (anti-mildew) and good management is the best choice.

Aspergillosis

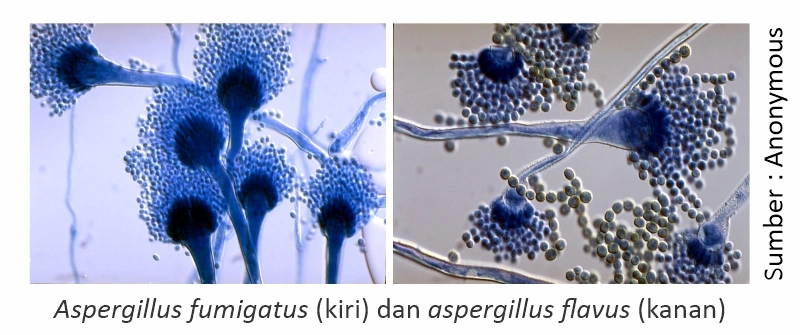

Aspergillosis is known as mycotic pneumonia, brooder pneumonia or fungal pneumonia. Called pneumonia because this disease mainly affects the respiratory system of chickens. Aspergillosis caused by fungi Aspergillus sp. The species that most often attack chickens are Aspergillus flavus and Aspergillus fumigatus. A. fumigate often found in organic materials such as eggs, husks, feed, and equipment (incubator machines). While A. flavus more often found in feed raw materials. Aspergillus it will produce a lot of spores. The spores are so small and light that they easily spread in the air and contaminate feed, husks, straw, grain, cages, etc.

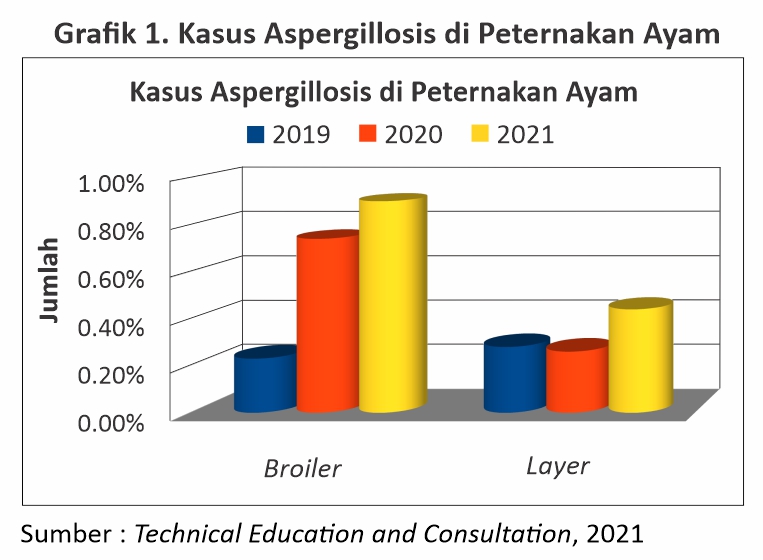

Based on the evaluation data of the last 3 years by the team Technical Education and Consutation Medion trend cases of aspergillosis in chickens (broiler) from year to year it rises slowly (see Graph 1).

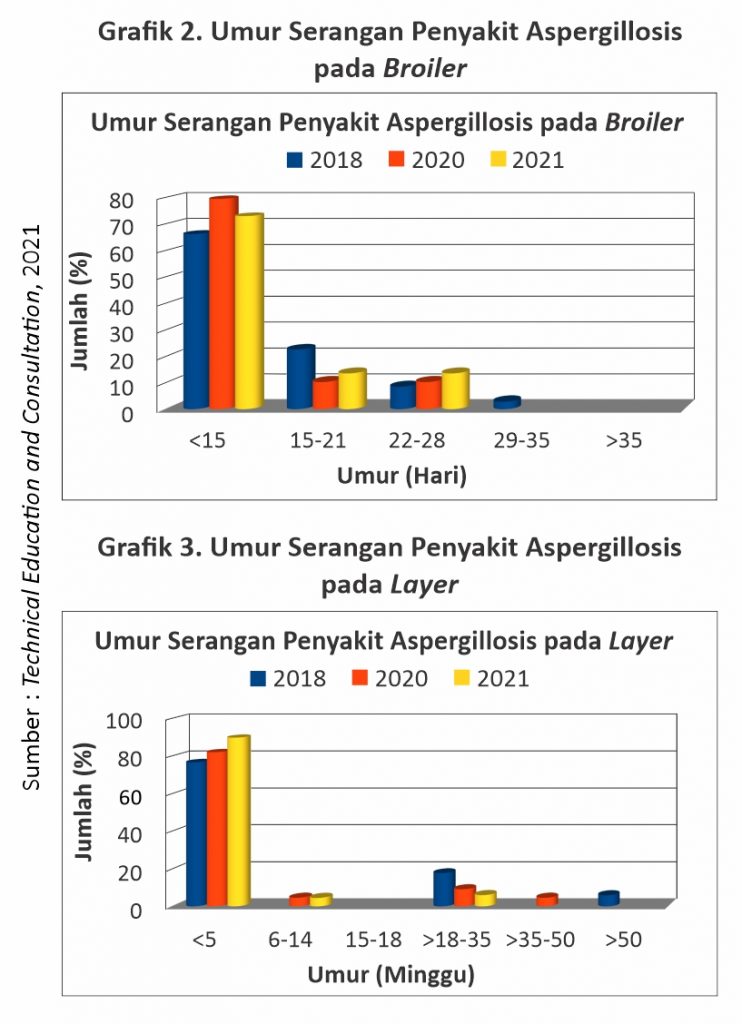

In Indonesia, aspergillosis in broilers (broiler) more often found in young age than old age. The chicken (layer), in addition to young age, cases have also been found in old chickens.

What are the dangers of aspergillosis? In addition to being pathogenic, aspergillosis in chickens can cause growth retardation and disruption of the immune system. The growth of mushrooms on the ration will also take some of the nutrients contained in it so that the intake of nutrients for chickens is insufficient. Not to mention, with mycotoxins (fungal toxins) produced by fungi Aspergillus sp. which is very difficult to eliminate and can lead to immunosuppression and even death.

The clinical symptoms of the acute form of aspergillosis that affects chicks include :

- Chickens do not want to eat or drink

- Sleepy

- Lazy move

- Breathing with difficulty

- Bluish head

- Spores Aspergillus sp. which enters the mucous membrane of the eye will develop to form plaque under the niktitan membrane so that it becomes inflamed and the eyes are covered with a thick yellow liquid. This symptom is commonly called aspergillosis ocular form.

While the clinical symptoms of aspergillosis chronic form that commonly affects adult chickens are :

- Decreased appetite

- Yellow stools

- Rough breathing sound with yawning, chirping, and open beak

- Ascites (accumulation of fluid in the abdominal cavity)

- Over time the chicken becomes thin

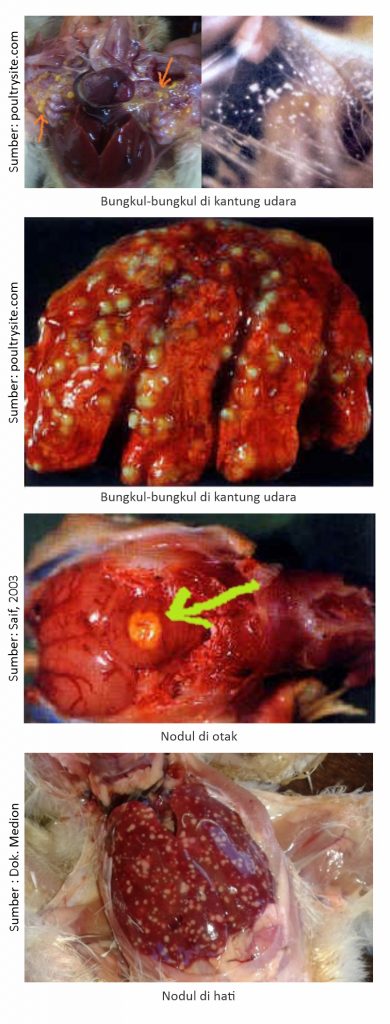

Having found clinical symptoms such as the above, when a sick chicken surgery is performed, anatomical pathological changes such as the following can be found :

- In the branching trachea found exudate caseosa (yellowish white)

- Ice packs on air bags

- There are caseosa nodules (yellowish-white lumps) in the lungs

- Nodules on the brain

- Nodules on the liver

Factors affecting mold growth

The presence of fungi in the ration is influenced by several factors, including:

1. Climate

Weather conditions during the harvest period to the storage of raw materials rations affect the increased growth of fungi. In tropical countries such as Indonesia, fungal contamination is very difficult to avoid because the climatic conditions with high levels of humidity, rainfall and temperature are very supportive of fungal growth. Indonesia is at high risk of fungal threats because this fungus grows and thrives at temperatures of 25-32°C and air humidity of 65-85%.

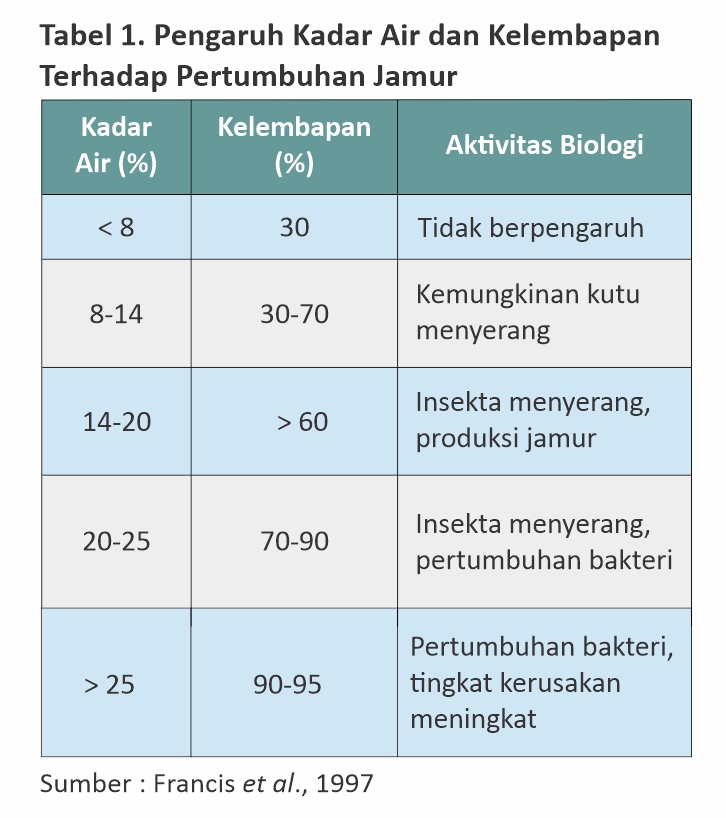

2. Water rate and humidity

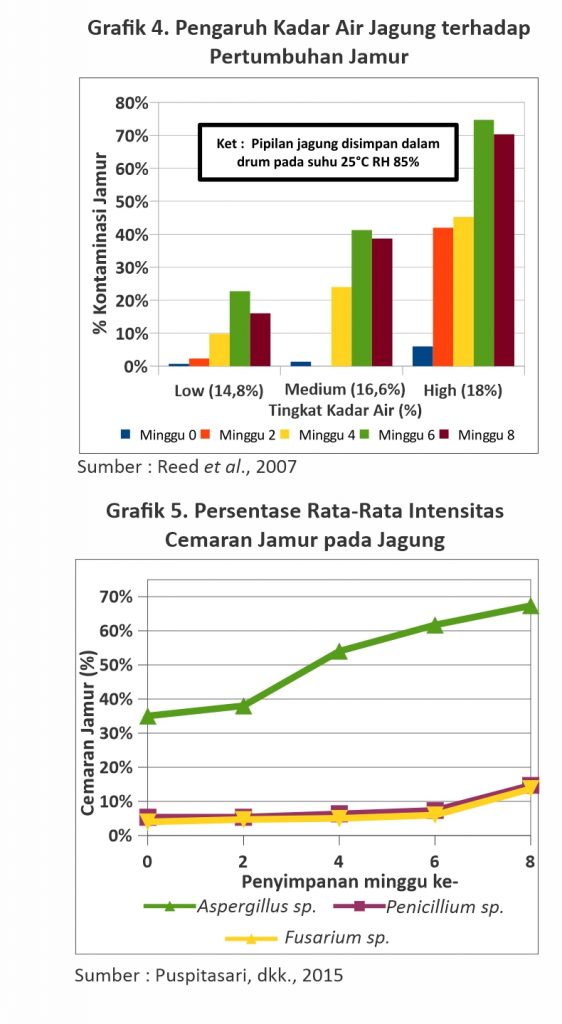

Raw material ration with a moisture content above 14% and the potential for mold.In addition, sthe higher the moisture content, the more potential for mold growth during the storage period.

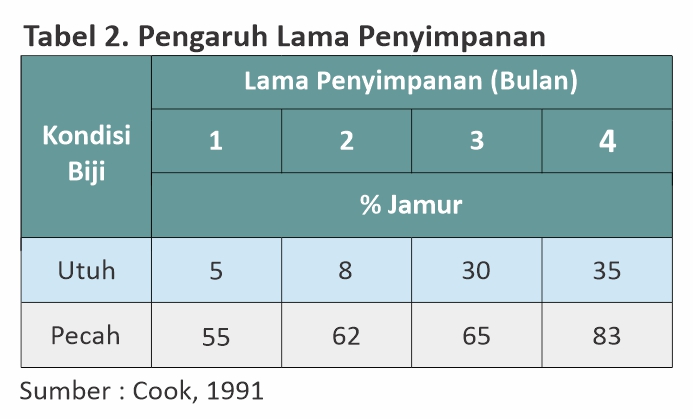

3. Grain conditions and duration of storage

The growth of fungi is influenced by the condition of grain that has been damaged, either due to excessive heating, grinding or due to insect damage. Mushrooms will be more and more when the seeds burst and are stored for a long time. In addition, poor storage conditions have the potential to cause contamination resulting in decreased nutrient levels of the ration. The shelf life of a good chicken ration generally lasts for 21-30 days from the date of production (batch). While the storage of rations in a damp warehouse will certainly cause damaged rations within 2-3 days. The longer storage of raw materials rations can increase the intensity of fungal contamination (graph 5. and Table 2.)

Errors in the storage of raw materials or rations in general such as insufficient ventilation and damp storage. In addition, the lack of use pallet under the pile of rations and visible rations attached to the wall. Although the water content of the ration that comes from the manufacturer or raw material ration of supplier it meets the standards, does not guarantee that the ration to be given to the chicken will remain of good quality if the storage is not appropriate.

Good ration storage

Good ration storage must be able to maintain the nutritional content in the ration. Some things to consider related to ration storage are :

- The warehouse has a storage capacity in accordance with the ration needs of the chickens we keep. A good Warehouse should not leak, avoid direct sunlight, temperatures ranging from 25-32°C with humidity no more than 70%, the position of the floor is higher than the ground and free from mice and fleas. In addition, the warehouse must have a design and layout good, so as to apply the system first in first out (FIFO: stored by date of arrival of raw materials rations) or first exipired first out (FEFO: stored by expiration date). It is very important that the stored rations are of good quality.

2. Rations should not be stored for too long. The average farmer has a stock of rations for 1 month. If the ration is stored for too long, then its nutritional content will decrease.

3. The cleanliness of the warehouse must be maintained. A dirty warehouse will cause mice and insects to breed comfortably in the warehouse. And if this happens, then fatal problems will arise, such as a decrease in the quality of stored rations.

4. The ration pile must be neat and there is a sufficient distance (at least 50 cm) between the wall and the ration pile. It is intended that the ration is not easy to clot and minimize the presence of rats.

5. Avoid using damaged packaging, such as perforated or moldy. Damaged packaging will cause the ration to scatter, and this will reduce the ration given to the chickens. And the falling ration ration will be a good medium for the growth of insects and rodents. On the chicken farm layer, often used repeated packaging. It would be better if this packaging was coded according to the cage. This is to minimize cases of disease transmission through packaging. And there should be a service life of this packaging.

6. Pay attention to the moisture content of the ration. A good ration should have a moisture content of no more than 14%. A high water content in the ration will lead to increased fungal contamination in the ration.

7. The ration should be put on top pallet. This is so that the ration does not come into direct contact with the floor of the cage. Rations are stored directly on the floor, without the use of pallet, will absorb water on the floor so it is easy to experience clumping. And this condition will cause the ration to easily overgrow with mold.

Treatment and control of Aspergillosis cases

In general, effective therapy to treat aspergillosis in chickens does not exist. Therefore, when Aspergillus sp. attack, the effort we can give is :

- Do culling in chickens, the condition is severe.

- Increase the body's stamina chicken by giving high doses of vitamins (vitamin high concentrate) like Fortevit.

- Effective therapy for aspergillosis is actually still undeveloped. However, to help relieve aspergillosis can be given anti-fungal cupri sulphate 1 gram/5 liters of drinking water for 3 days as well as Nystatin 100 g / ton of feed.

- Give antibiotics to suppress secondary (bacterial) infections. For example, by giving Neo Meditril for 5 consecutive days.

The considerable losses due to this fungal contamination make us realize that prevention efforts are important to do. For this reason, some preventive measures that we can do are :

- Sanitation and disinfection of ration warehouses, egg tray, egg crate, Chicken Basket, etc., before use.

- Check the quality of raw materials ration regularly, especially when the arrival of raw materials.

- During storage of raw materials or rations, should be checked regularly and if identified there is a fungus that grows, immediately heat (>71-100°C) or drying rations so that the fungus dies.

- The growth of fungi (mold inhibitor), especially the rainy season. Fungitox it is an organic compound (organic acid) and silicate mineral complexes. The administration of this organic acid plays a role in inhibiting the growth of fungi and optimizing the health of the digestive tract so that the health of chickens increases. While the silicate mineral complex will bind mycotoxins and prevent their negative effects.

- In addition, it can be added to the use of herbal remedies that can prevent liver damage such as Heprofit. Heprofit is a liquid preparation containing neem extract protects liver cells from damage and optimizes chicken performance.

- Aspergillosis not only contaminates rations, but can also grow in husks or cage equipment made of wood or bamboo. Therefore, its cleanliness and humidity must be observed. If the postal enclosure system, use a dry husk, increase the thickness of the husk (8-12 cm) and immediately take and replace the wet husk.

- Clean the ration place and drinking place. After brushing and washing, the ration and drinking place are soaked in Medisep. When using a drinking gutter (PVC pipe), brushed and rinsed with clean water.

- Wet and lumpy ration residues in the ration site must be cleaned immediately so that they do not become overgrown with mold.

- Avoid the activity of leaking rations with water to stimulate the chicken's appetite excessively because it can increase the risk of mold growth.

- For breeders self mixing, increase machine cleaning period grinder or mixer, for example, once every 2-7 days. The rest of the ration, especially in the form of powder contained in both tools will be a source of fungal contamination in other ration raw materials.

- Make sure ration storage is done properly.

The Importance Of Choosing Quality Raw Materials

Ration greatly determines the productivity of livestock so that the quality control of raw materials and rations so very important to be done by farmers. We know that the quality of raw materials in the field is always changing depending on the region, weather, season, post-harvest handling, storage, etc. If it is not controlled for quality, it will harm the breeder. Moreover, the cost of rations takes the largest share in the cost of production, which is about 70-85%.

Some things that must be done and considered when choosing raw materials, including :

- Knowing the storage time of raw materials in supplier.

- We recommend that farmers have several alternatives supplier raw material ration as a comparison of quality and price. It is also useful if suddenly there is supplier who can not / stop supplying raw materials rations to our farms.

- You should not accept ration raw materials whose quality is not up to standard.

- When raw materials come to the farm, immediately record no. batch, name supplier, date, and amount of raw material load. After that, conduct a physical quality check and chemical quality (if necessary) of the received raw materials. After inspection, the next raw materials stored in the warehouse rations, and sorted by no. batch as well as the date of arrival. As for some examples of initial checks when the arrival of raw materials rations, among others:

- Check the moisture content (KA) of raw materials ration (eg corn) using digital measuring instruments. A good rate is 14%. If there is no other choice of raw materials with low KA, then raw materials with KA >14% must be dried in the sun before being stored in a storage warehouse.

- There should be no grains of corn whose base is blackened/discolored due to fungal or insect attack.

- There should be no beard crumbs (corn cobs) on the received corn raw materials.

- The color of the corn should be yellow. If it is pale in color, it should not be accepted.

- For Bran / Bran, choose a smooth texture. When clenched then released, Bran / Bran good not directly “ambyar " but restrained with The Shape of a fist. But if the result of a fist immediately falls apart, it means more content of milled husk than Bran / husk. The smell should not be rancid, must be a typical Bran/Bran smell.

- Apart from the physical aspect, the examination of raw materials ration can also be done by looking at the chemical quality. It's just that for the quality of this chemical must be tested in the laboratory, although some levels of nutrients some can be tested through rapid test (test kit).

Although fairly rarely found on farms, this disease still should not be taken lightly. Do not let the fungus contaminate first to cause losses that are not comparable to the performance of the chicken obtained. May be useful.