Poultry business is one of the industries that are continuing to improve in the face of transitions or changes in trends leading to the modern era. Efficiency is one of the main keys to increasing competitiveness in that era. Currently, the management of maintenance in poultry farming seems to be continuously modernized so that its effectiveness and efficiency can be improved. Simple modernization efforts such as starting to replace conventional tools and cage systems into semi-modern ones are also important. This is a stepping stone to change the order of cultivation towards mechanization as a whole.

The current situation in the field, non-industrial poultry farmers are often still confused with fluctuations in the selling price of poultry products and the high cost of livestock rearing facilities. Therefore, current thinking is more focused on how to carry out the cultivation process by minimizing losses.

The development of poultry farming including broilers is not without constraints. Especially since broiler conditions now have less feather growth and are easily stressed and sensitive to the environment. Of course, this must be anticipated from the beginning of the maintenance of chickens, especially during critical periods of maintenance.

In addition, the existence of government policies regarding the Prohibition of use Antibiotic Growth Promoter (AGP) or growth-promoting antibiotics in feed that have been going on since the beginning of 2018. The ban led to a decrease in performance, deterioration of the gastrointestinal tract and an increase in production costs in broilers and layers. The ban on the use of AGP makes farmers have to increasingly focus on various improvement measures in maintenance management. So that the negative influence on the performance of broilers we can press to a minimum.

Broiler Performance

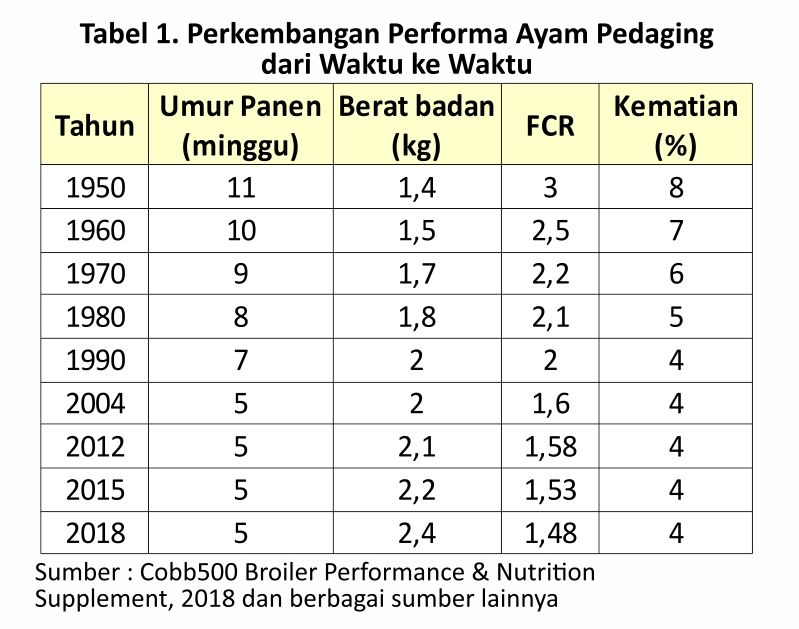

On the other hand, the genetic development of broilers is currently in line with genetic quality improvements made by experts. The main purpose of raising broilers is to produce meat. Therefore, experts also continue to develop strains chickens that produce quality meat production with a high level of feed efficiency. Until the last 2018, the development of broiler performance can be seen in Table 1.

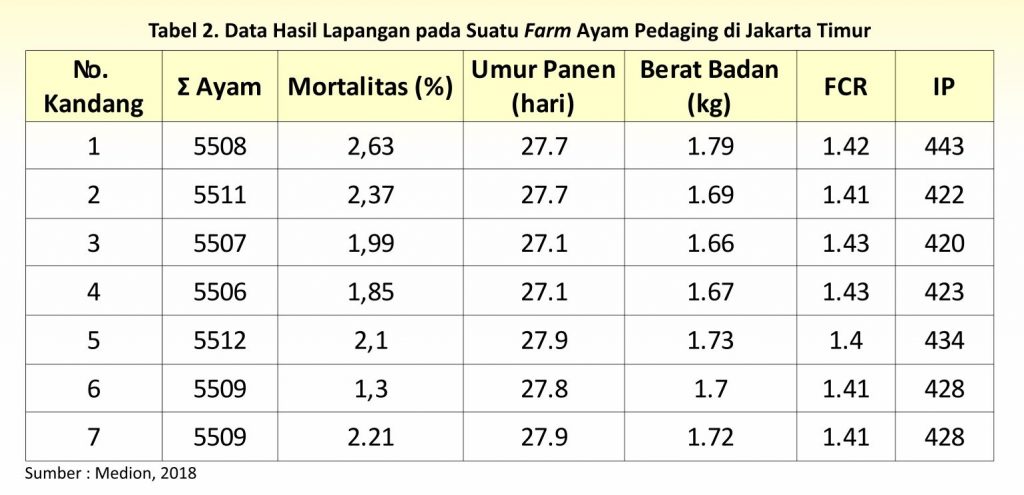

The faster and more efficient growth in converting feed into meat (FCR) certainly needs to be supported by the implementation of Excellent Maintenance Management. It is not impossible that the performance of the broiler obtained exceeds the performance standards set by the breeding company/breeder. One of them is shown in the data of a farm in Table 2.

Optimal Maintenance Management, The Key To Success

Rearing management is the key to successful chicken rearing.

- Management brooding period,

Early success has a share of 50% and even 90% of the success of chicken rearing. Due to a series of processes that occur in the body of chickens during brooding period, so important, then attention and intensive handling should be applied at this time. Failure at this time will make it difficult to achieve optimal productivity in the next phase of raising chickens. For that since the chickens are harvested, we need to prepare the cage immediately so that when the schedule chick in the cage is ready.

Cleaning the cage should be done thoroughly, ranging from washing the cage, equipment, fertilizer expenditure (litter and feces), up to liming and disinfection. Things to keep in mind regarding the preparation of the cage are:

- Use detergent when washing the cage, the detergent can remove organic matter such as residual feces, mucus or chicken blood that may be left behind. Why is this necessary? Because organic matter is a comfortable place to live for seedlings. In addition, one of the decisive factors for successful disinfection is the absence of organic matter.

- Litter the container must be removed from the cage before cleaning and disinfection is carried out. Stack litter those that still exist in the cage environment can be a good growing place for Disease seeds, so it is feared that they can be a source of disease transmission.

- In addition to washing equipment (chicken feeders and drinkers), do not forget to drain the water reservoir. This prevents the growth of biofilms, which are home to bacteria such as Escherichia coli causes of colibacillosis.

- The cage rest period is at least 2 weeks after the cage is clean, not from the moment the chickens are harvested. The washing or cleaning time of the cage can be shortened however not for empty cages. It aims to break the cycle hindup seed disease environment cage.

After the preparation and rest of the cage is done, the next stage is the creation of the area brooder it begins with the spread of litter or husk as needed. Recommended thickness litter initial about 7.5-10 cm (Cobb Brooding Guide, 2016) and spread evenly in the area chick guard. In the first 1 Week of preservation in time brooding period,, there is no harm in using new newsprint/chick paper above litter.

The next step is to create an account (chick guard). In the making chick guard it is advisable to use zinc and in the form of a circle or ellipse. Zinc material can absorb heat, so it is expected to conduct the required temperature for chicks. While The Shape of a circle or ellipse can prevent chickens from stacking in corners.

For extents chick guard itself can be adapted to the DOC population to be kept in one chick guard. Let the density of chicken in one brooder not too much of a maximum of 1,500 heads, so that the cage operator is more optimal in me-monitor condition of chicks. Area calculation criteria chick guard can be seen from the current density of time brooding period,, generally 50 – 60 heads/m2.

- Nutrition

Feeding and drinking water directly when chick in will accelerate the absorption of the yolk and trigger the process of development of the gastrointestinal tract. In the critical period, the faster the chicks consume feed, the faster the digestive organs, immune system, thermoregulatory system and skeleton of the Chick's body develop, so the weight standard is quickly achieved. Therefore, when the DOC arrives, it can be given 2-5% sugar water (20-50 grams in 1 liter of drinking water) or Gingertol especially when chick in can help restore DOC's energy lost during the trip so that it can be refreshed and performance remains optimal.

During the maintenance period, ration/feed and drinking places should be provided in accordance with the number of chickens. The distribution must also be evenly distributed so that all chickens can eat together. We must ensure the distribution of chicken feed is sufficient, so the place to eat and drink should be adequate for all chickens, lest there are some chickens that can not compete for feed with other chickens.

So that we do not miss when the maintenance of chickens at a critical time it needs to be done check and re-check against chicks. The check can be carried out 2-3 hours after the first feeding by touching the Chick's gizzards and legs. Chicks are said to be comfortable at least 75% of the sample when touched cemboloknya felt full, supple and soft, and when touched feet feel warm. This reflects the adequacy of nutrition both feed and drinking water, heating , litter and air circulation.

- Air sufficiency

The availability of clean air is very important because one of the components of air is oxygen gas which plays a major role in the metabolic process of chickens. If there is less oxygen in the cage, the health of the chickens will suffer. Especially if in the cage a lot of harmful gases such as ammonia and CO2.

To create clean air, one of them is by setting the cage curtain open and close. However, this arrangement must be adjusted to environmental conditions, especially temperature and wind speed around the cage. In the rainy season and very cold weather, install additional curtains (inner curtains) to protect the chicks during the period brooding period,. Never close the cage brooding period, entirely without the slightest gap. It can reduce the content of O2 and increase toxic gases such as CO2 as well as ammonia. As a result, the respiratory system of chickens will be disrupted.

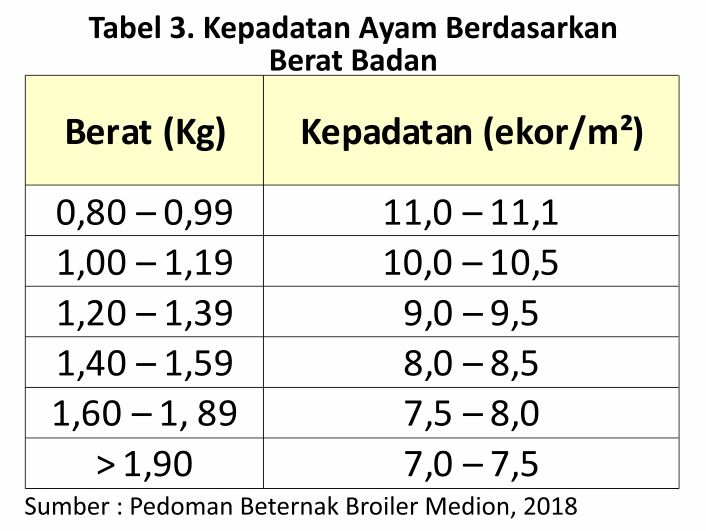

In addition to the arrangement of curtains, the adequacy of clean air can be done by adjusting the density of the cage. Cages that are too dense can cause the temperature in the cage to be more stuffy and hot, causing increased drinking water consumption which results in wet stools. This can trigger high ammonia gas. We recommend that the density of chickens in cages is set according to the age/ increase in chicken body weight (Table 3).

If applying a closed cage system or cage closed house, then the temperature and humidity can be controlled to achieve comfortable conditions for chickens with a minimum ventilation system and closed curtains. This closed cage system is automatically controlled by an electronic system, which regulates from chicken feeding, air regulation, cage temperature, to the relative humidity level in the cage.

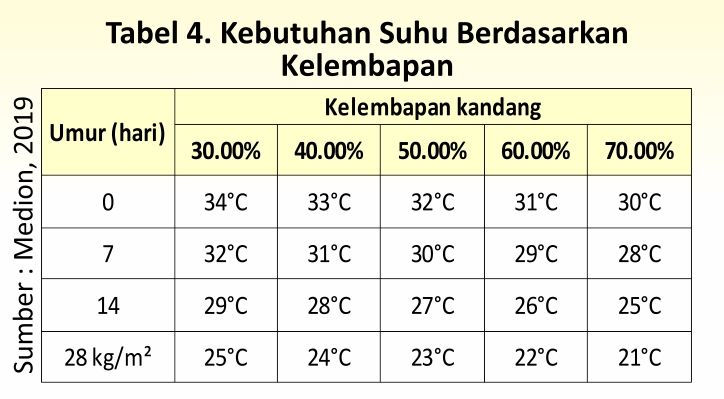

The effective temperature felt by chickens in this case is also influenced by the level of air humidity. Air humidity reflects the amount of water contained (bound) in the air. The more water that is bound in the air, the more humid the air, and vice versa. The humidity level will affect the temperature felt by the chicken. Table 4 shows temperature standards based on comfortable humidity in broilers.

- Ammonia control

Specifically, the appearance of ammonia is caused by urea and uric acid (C₅HĪOĪN4Ī) as the end product of purine metabolism from chicken faecal waste that has not been handled. Too high a content of salt and coarse protein in the feed can also lead to wet stools (diarrhea). This condition will interfere with the work of the kidneys in removing uric acid, so that the stool becomes wetter and the uric acid content (“raw material” ammonia, red) is higher.

Farmers can suppress ammonia at the lowest possible level so that chicken productivity is not compromised. Such as controlling levels of feed nutrients, management litter well, adjust the density of the cage, pay attention to air circulation to increase the use of blower or fan (fan). Should also be given Ammotrol because the amount of feces produced at the age of adult chickens is usually more so that the ammonia produced will increase.

Health Management

To keep chickens in good health, it can be done by :

- The vaccination Program according to the condition of the vaccination destination area is to bully the formation of immunity/antibodies from the body to prevent infection. From the description of diseases that attack broilers, vaccines that must be given to broilers are ND, Gumboro and AI. However, it is worth considering IB and korisa vaccinations if the area is prone to IB and korisa diseases. The program of vaccination activities can be adjusted to the conditions of each farm (history and level of disease vulnerability).

- Herbal supplements and medication

The impact of the ban on the use of AGP occurs in broiler farms is not the achievement of the performance of chickens, namely body weight, feed conversion ratio (FCR), the harvest period, as well as a decline in health, especially gastrointestinal health. Related to this AGP ban, there are actually ways to keep making chicken performance good, one of which is the use of herbal supplements (fitobiotics). However, attention must also be paid to maintaining the Biosecurity of the cage and equipment and the quality of the feed provided. If there have been cases of infection, take appropriate treatment based on diagnosis, drug selection, and dosage and rules of use.

Herbal programs can also be used as supporting health programs. The preparation and implementation of the herbal program aims to prevent disease, improve health and accelerate recovery if livestock is attacked by disease. This herbal Program is not standard, but can vary in one farm with the farm the others. It can be adapted to the breed of chickens, the purpose of Use and the conditions during maintenance.

Administration of Imustim aimed at increasing immunity through an increase in compounds that play a role in fighting foreign substances that attack the body of chickens.

In the second week, giving Kumavit is a good choice for the maintenance and natural improvement of chicken performance. Then Fithera given at this age as prevention given the high cases of bacterial diseases (Korisa, CRD, Colibacillosis) and protozoa (coccidiosis) in broilers is still an enemy to the world of animal husbandry.

The third week of maintenance, give Imustim after vaccination as an immunostimulant that can accelerate the increase in antibody titer vaccination results. In addition, also give Fasbro to maintain the digestive tract and accelerate growth. This is because Fasbro is one good choice of herbal supplements to help optimize FCR, improve appetite and carcass quality in chickens.

- Strictly biosecurity

Biosecurity aims to prevent disease seeds from entering the farm and spreading out of the farm. As farmers, we are a must to implement biosecurity strictly. Traffic control of vehicles and livestock facilities needs to be done. Because it can act as a vector/carrier of disease seeds. No less important is the arrangement of the visit schedule of the operator / PPL who oversees several cages, when the visit must be started from new young chickens to old chickens or healthy chickens to sick chickens. If the previous visit to the sick chicken should not visit the chicken coop healthy because the operator can be a source of disease carriers.

Biosecurity activities that are equally important are sanitation and disinfection, namely ensuring that TRA and TMA are routinely washed and disinfected using disinfectants such as Medisep, Zaldes or Sporades. As well as disinfection of guest cars, visiting guests, and cages for contents, especially during an outbreak of the disease. This disinfection will minimize the number of disease seedlings in the home environment.

Maintenance Evaluation

In a maintenance needs to be done recording or recording. Recording it serves as a” detective " in evaluating the success of a livestock business and knowing irregularities in the management carried out. Many farmers are still ignoring recording this is so that when a case occurs it will be difficult to analyze and the causes and solutions for the next period.

Monitoring it is also important to do prevention before the disease enters and infects into a farm. Because the costs incurred for prevention are less compared to treatment. Things that should be well recorded in recording among them are the population, the number of rations, depletion (shrinkage), body weight, and health programs.

Based on the reviews above, it can be pursued an optimal strategy to achieve maximum performance targets. If we do not do it then the performance of the chicken can not be achieved on target, cost or the costs incurred are increasing, and finally the profit from maintenance cannot be maximized. Greetings.