Some breeders have proven that by using closed house able to improve livestock performance and have better competitiveness. System closed house is a cage system that can remove excess heat, water vapor, and harmful gases (CO, CO2, NH3) that is in the cage but on the other hand can provide the needs O2 for chickens so that optimal chicken performance (Poultry Indonesia, 2011).

The development of farmers who use closed house, good full closed house or semi closed house more and more every day. The goal is to improve the performance of chickens (performance index) so that the farmer's profit is greater. Weather forecast (global warming or global warming) or genetic changes require us to always innovate so that our performance and profits increase.

Chicken Development Broiler Management

Poultry broiler it is a breed of superior breed of chicken crossed nations that have the ability to produce meat. We can not deny that the current genetic chicken broiler has developed very rapidly. Created with incredible genetic potential, chickens broiler currently or already commonly called Chicken broiler modern models have characteristics:

1. Fast growth

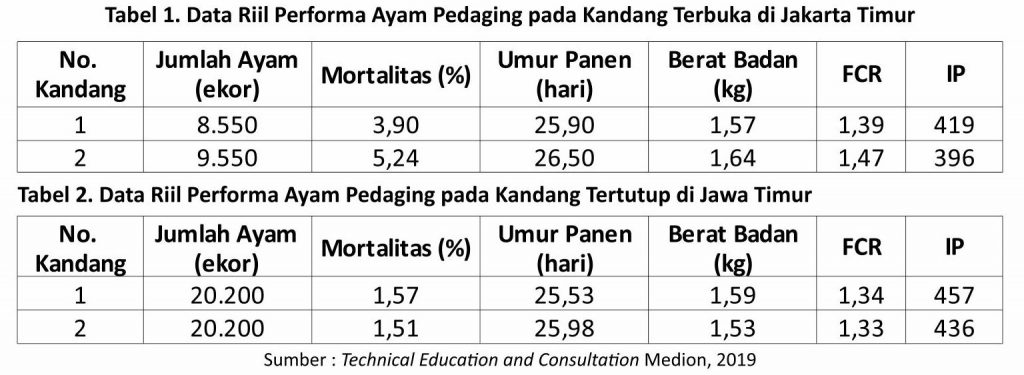

Poultry broiler modern women can reach a body weight of 2273 g within 35 days (Cobb 500 Broiler Management Performance & Nutrition Supplement, 2018). From year to year the growth is getting faster and more efficient in converting feed into meat (FCR). Even if the maintenance management is implemented very well, it is not impossible when the performance of chickens broiler obtained exceeds the performance standards set by the nursery company/breeder. An example of this is on a chicken farm broiler in the East Jakarta area. Although farm the use of cages open house (open cage), from our fieldwork reports from 2003 to 2017, the performance of chickens always reaches the target followed by the value index performance (IP) more than 300. Even in 2018, the IP value was already over 400 (see Table 1). While perfoma chicken broiler those kept in closed cages in East Java showed even better results with a small FCR and IP above 400 (see Table 2).

2. Bigger breast meat

The meat in the breast is of better quality than the rest. This breast meat has a softer texture and less fat and cholesterol levels. For these reasons, geneticists are constantly trying to optimize the growth of meat in the breast. However, this condition eventually leads to consequences, where chickens broiler becomes more stooped and less activity of his movements. To anticipate the low consumption due to the lack of chicken movement activity, we must provide a place to feed and drink that is quite comparable to the number of chickens kept.

3. Fewer feathers

Feathers are parts of the chicken's body that have not been widely used by humans. But to form it requires a considerable intake of nutrients. With fewer feathers, the use of feed for weight growth will be much more optimal. It's just that with this condition chickens become more sensitive to changes in temperature and humidity of the environment. For that reason, in the maintenance of chickens broiler, the breeder needs to periodically control the temperature and humidity of the cage every day.

Chicken development broiler this can be the most compelling reason to change the cage from open house to closed house. This is what often makes farmers change their minds. Chicken productivity is increasingly difficult to achieve optimal, making farmers look for solutions to achieve this. And one of them is to make the cage as comfortable as possible for the chickens.

Chicken Performance Index broiler when using cages open house range 260-370 while when the cage is converted into closed house can increase to 400-420 (Trobos, 2018). The higher the achievement of IP then the farmer's profit will be greater. For comparison, when using a cage open house chicken broiler harvested at the age of 30 days with a weight of 1.8 kg and feed conversion ratio (FCR) 1.52 – 1.53 while being kept in cages closed house with the same age harvest weight can reach 2-2.1 kg with FCR 1.5 (Trobos, 2018). In other words, chicken performance increases with better feed efficiency.

Know The Type Of Closed Cage

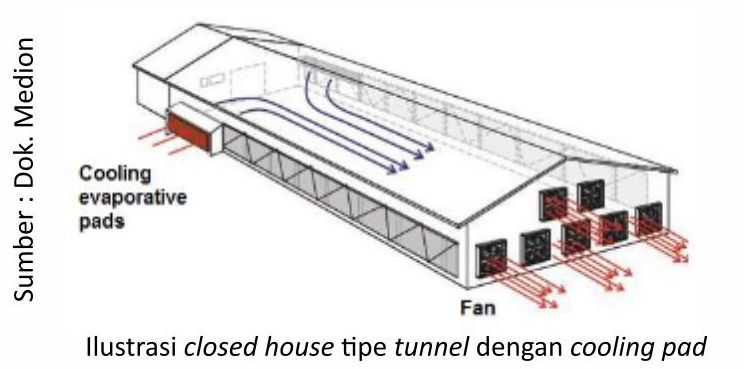

Closed house type tunnel

This type is the most widely used in Indonesia. Tunnel or tunnel, this type of closed Cage is described as a tunnel where air will enter from the front (inlet) and will be pulled back to flow along the cage and removed with the help of an exhaust fan.

Tipe tunnel ini pun dibagi menjadi dua, yaitu tunnel dengan menggunakan cooling pad (full closed house) dan tanpa cooling pad (semi closed house). Usually a full closed house is used for areas with low humidity levels and high temperatures. While the semi closed house is usually the result of an upgrade from an open house cage and want to try to switch to a closed house cage.

- Closed house type cross flow Exhaust fan installed along the sides of the enclosure, and the inlet on each opposite side, so that the air moves perpendicular to the length of the building. This type produces low wind speeds and is widely used when the phase starter and in low-lying areas.

Fittings Closed House

The ventilation system becomes the staple of a closed house. And the completeness of this ventilation system consists of fan (fan), evaporative cooling pad, controller and the cage curtain.

1. Fan (fan)

Fan (fan) is a device that creates air movement. In general, there are 2 types of fans, namely exhaust fans and blowing fans.

Exhaust fan serves to suck the wind and blowing fan serves to blow the wind. Daya dorong blowing fan sangat terbatas, yaitu maksimal sejauh 12 meter oleh blowing fan 36 inch berkapasitas 20.700 m3/jam pada tekanan 50 Pa. Therefore, the closed house system uses an exhaust fan.

The parameters that need to be considered in the operation of the fan are the number of fans on and the length of time the fan is on. The selection of the right fan is necessary in order to produce the appropriate air speed and temperature with minimal electrical power consumption.

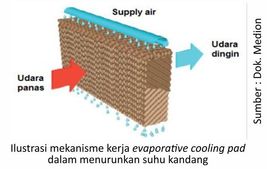

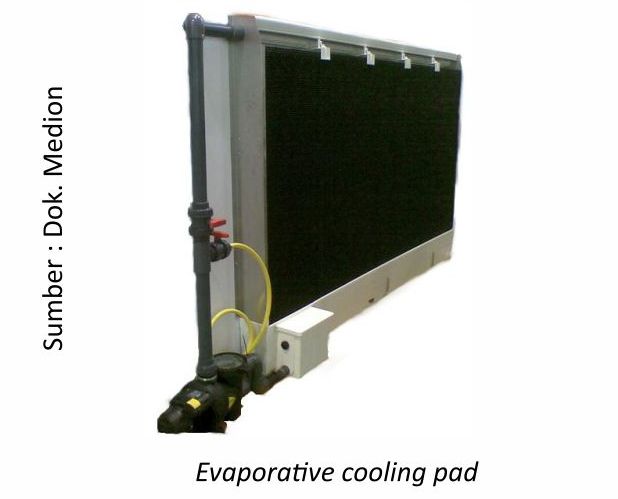

2. Evaporative cooling pad

Evaporative cooling pad is an air cooling device that utilizes water evaporation. Evaporative cooling pad is connected to a pump that will wet it with water. When hot air from outside the cage enters the cooling pad, the water will take heat energy from the air so that the water will evaporate (evaporation process) and result in a decrease in the temperature of the air entering the cage. Breeders are not recommended to wet the cooling pad when the humidity >75%, because it will increase the humidity of the cage.

Evaporative cooling pad also serves as a filter for air entering the cage. Bulkhead-bulkhead cooling pad prevents air impurities (large) to enter the cage, so that the incoming air becomes cleaner.

3. Controller

Controller or called climate controller is a tool to control the temperature and humidity in the cage. This tool is often referred to as the”brain " of his closed house. This Controller can be programmed in such a way with the target of making the atmosphere of the cage, the temperature and humidity comfortable for chickens. Controller akan mengatur nyala atau matinya kipas (exhaust fan) maupun pompa pada evaporative cooling pad.

4. Curtain cage

The cage curtain is the side cover of the cage so that the chickens are protected from outside interference. In addition, cage curtains are also useful for :

- Helps maintain the air temperature in the cage (especially during periods brooding period,)

- Prevent rainwater splashing

- Provide emergency ventilation in case of power failure (Dead fan)

- Generate the required static pressure in the system closed house

Cage curtains combined with the system winch (pulley), to facilitate the rapid raising or lowering of the curtain, it is enough with an operator.

Reviewing temperature and wind speed mismatches

Symptoms over heating seringkali occurs at the age of 21 days and over, when the chicken's body broiler it's getting bigger and producing its own heat. Different ages of chickens require different temperatures and tolerances to different wind speeds (eg DOC = still air, 1 Week = 0.5-1 meter/SEC).

It's a great way to warm up your body (wind chill) the speed of the wind (wind speed). Wind speed in the cage is influenced by many factors including :

- Fan : capacity, tightness belt, hygiene blade, motor power decreasing with service life, uniformity between fans.

- Cage density : check the side curtain with holes or other holes (ceiling, building connections) in the cage that cause air to enter through the hole, not through inlet (cooling pad) on the front of the cage.

The mismatch of the two things above can cause turbulence so that the air flow and wind speed in the cage is not optimal. Airflow velocity in the enclosure closed house can be measured , conducted via windmeter.

The maximum wind speed in the cage is 3-4 meters / second (COBB Broiler Guide, 2018). The higher the wind speed, the greater the effect of lowering the temperature felt by the chicken's body. The negative impact of high wind speed is to fly the dust from the base of the cage which triggers breathing disorders due to dirty air coming from dust. In addition, the perceived effective temperature of chickens that is too low will result in reduced consumption of chicken feed. This condition can cause feed intake not achieved.

The wind speed is also affected by the cage curtain. Curtain cage on the cage closed house cover all sides of the cage so that the chickens are protected and to maintain the air temperature in the cage. This curtain will prevent direct wind exposure to the chicken's body.

Basic management of ventilation and air circulation

On the cage closed house, the ventilation and air circulation settings are regulated by the fan (fan). Fanfan) serves to remove hot air from the cage and create gusts of wind into the cage closed house.

Air circulation and temperature in the cage has a vital role in closed house. Without good ventilation management, good chicken performance is impossible to achieve. Thus supporting air circulation and temperature such as fans and evaporative cooling pad should be noted.

Meanwhile, the minimum ventilation is the minimum air required to replace the air in the cage so that it remains optimal for broiler. Minimum ventilation provides sufficient oxygen (O2) and remove moisture in the cage. Excess water vapor can increase ammonia levels (NH3) and cause wet husks, thereby increasing the risk of developing diseases in chickens. Minimum ventilation requirements must be met in the enclosure closed house. One of the symptoms that occurs if the minimum ventilation is not met is the uneven spread of chickens. Chicks up to 14 days have not been able to regulate their body temperature properly and chicks up to 7 days should not be exposed to drafts from fans, but the minimum ventilation requirements must be met.

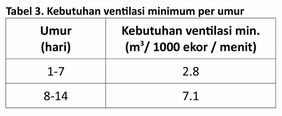

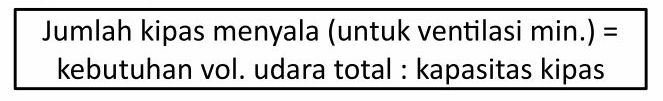

Minimum ventilation is achieved by regulating the number of fans running and their duration. A guide for calculating the number of fans on for the minimum ventilation requirement is shown in the following formula.

Regular fan maintenance will certainly increase the life of the fan and prevent damage during Operation. Some things to consider in fan care:

- Clean the belt (belt) fan and blade fan with soapy water before chick in.

- Before chick in, ensure the tightness of the fan belt and fan motor rotation, so that the wind speed generated by each fan is uniform.

- The maximum wind speed in the cage is 3-4 meters / SEC. Wind speeds that are too high can blow away the husk dust so that it can cause respiratory disorders in chickens.

Treatment Evaporative Cooling Pad

Evaporative cooling pad serves to cool the incoming air by utilizing water evaporation. During the period brooding period,, recommended pump evaporative cooling pad not operated. Running pump evaporative cooling pad can produce air that is too cold for the chicks during the brooding period,.

Pump evaporative cooling pad operated only if the temperature in the cage above 28°C and in chickens aged over 14 days. It should be noted that by operating the water pump on evaporative cooling pad will affect the increase in air humidity. It is also not recommended to wet cooling pad when %RH is above 75%.

Evaporative cooling pad who often wet the water and exposed to sunlight will be at risk of the appearance of lichen on the body cooling pad. To prevent this, it is necessary to spray evaporative cooling pad at least once every month by using a disinfectant solution (such as Medisep). The disinfectant solution will prevent the growth of moss and bacteria on cooling pad. Use low pressure spray instead of spray high pressure deep cleaning cooling pad.

Evaporative cooling pad equipped with curtains on the inside of the cage. Inlet curtain cooling pad serves to regulate the opening gap for air to enter the cage. Air gap inlet opened from the top of the inlet curtain cooling pad. Magnitude of the air gap inlet or curtain openings inlet cooling pad adjusted to the desired air velocity in the cage. Air velocity out of inlet (before entering the cage / before leaving inlet) the recommended is 3.5-4 m/s.

Signs of ventilation problems

Uneven airflow in the cage leads to disruption of the growth and performance of chickens. Therefore, observe the behavior of chickens and around the cage to determine ventilation problems that occur:

1. Chickens collect in the middle of the barn

Chickens gather in the middle of the cage or as if avoiding the edges / sides of the cage. This is due to too slow wind speed. Generally, the condition of the wind speed is too slow found on the left and right sides of the cage, causing the temperature on the left and right of the cage to be hotter than in the middle of the cage. Therefore, chickens will tend to avoid these hot areas (also called Regions dead spot). This problem can be solved by minimizing the gap in the curtain opening inlet cooling pad or modify the roof with the addition of deflectors in the ceiling area. With the installation of deflectors on the ceiling causing hot air to gather in the area of minimal wind flow can be avoided.

2. Chickens gather on the left and right sides of the cage and tend not to move or sleep much

This sign is due to wind speeds that are too fast or strong, which gives an impact wind chill effect a big one, so that the chicken gets cold. Cold chickens will reduce activity so that the energy from the feed is not wasted for movement activities, and is used to heat the body. Thus, it will have an impact on reducing feed intake and slowing growth broiler. This can be remedied by widening the gap of the inlet curtain opening cooling pad or turn off some fans that are on. Ensure that the effective temperature required by the chicken is reached.

3. The spread of chickens is uneven

An uneven spread of chickens indicates an uneven temperature of the cage. Uneven cage temperature can be caused by air holes. The hole in the cage closed house it's a big deal. Air holes cause other problems including:

- Causing many areas with minimal airflow (”dead areas").

- Hot and humid air will be in the area outlet, and the sides of the cage.

- The working power of the fan is getting heavier because it has to draw air from the leak hole.

Locations that need to be considered because of the frequent leakage of air holes are:

- Cage curtain connection.

- Upper floor trusses (air outlet from second floor to first floor).

a) wet / damp husk

A wet or damp husk indicates a too slow wind speed. During the production period, a lot of gas and water vapor is produced. 80% of the water consumed broiler will be excreted into moisture that must be removed from the cage. Water vapor that is not wasted through ventilation will be absorbed by the husk and cause wet husk.

B) strong smell

One of the common problems that arise in chicken farms is the problem of cage odor. A strong-smelling Cage is usually caused by a high content of ammonia gas. Ammonia Gas has a high irritating power, especially on the mucous membranes in the eyes and respiratory tract of chickens. When we enter the cage and the smell of ammonia is smelled, it means that ammonia levels are above the threshold (>20 ppm). Beyond this safe threshold, ammonia will cause harm to chickens, both in the form of damage to the eye and respiratory membranes.

Some causes of increased ammonia levels:

- Obstructed air circulation system

- Cage density is too high

- Management litter less than optimal

- Chicken feces are wet

Therefore, some measures to prevent increased ammonia levels are to:

- Regulation of air circulation.

- Set the appropriate cage density.

- Management litter the good (do pembolakbalikan litter regularly every 3-4 days and pay attention to leaks from chicken drinking places).

- Check and correct the nutritional quality of the ration (so that the feces do not get wet).

Usage closed house in the chicken business broiler it does require higher capital at the beginning of construction, but if it has been operating with a population capacity of tens of thousands or millions of chickens, production costs will be cheaper plus the quality of chicken is superior. Greetings.