Question

Mr. Adib – by Email

Is it safe to use paracetamol in chickens that are about to be harvested? For example, in broiler chickens experiencing heat stress at an age close to slaughter?

Answer

Thank you, Mr. Adib, for your question. Broiler chickens are prone to heat stress because their body temperature is highly influenced by environmental temperature. An increase in ambient temperature directly causes a rise in the chicken’s body temperature. Poultry, including broiler chickens, do not have sweat glands, and almost their entire body is covered with feathers, making heat dissipation less efficient (Damane et al., 2018). The regulation of body temperature in poultry relies entirely on physical mechanisms such as heat transfer through direct contact with solid objects (conduction), heat transfer through liquid or air mediums (convection), heat transfer without any medium (radiation), heat loss through evaporation from the body (evaporation), and the widening of blood vessels (vasodilation).

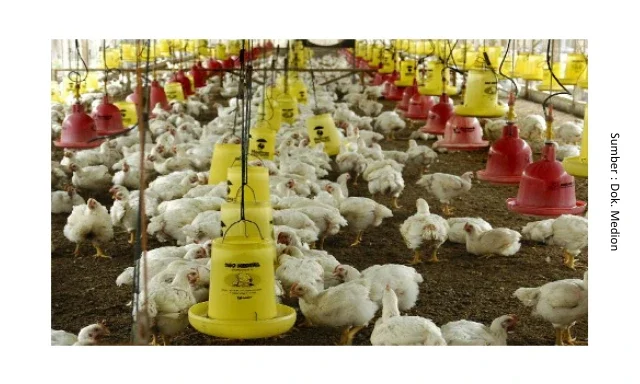

In addition, broiler chickens have a high metabolic rate, which leads to the production of a large amount of body heat. When the environmental temperature rises, the accumulation of internal heat also increases, making chickens more susceptible to heat stress (thermal stress) (Hidayat et al., 2020). During the third and fourth weeks of rearing, broiler chickens experience an increase in feed consumption that triggers higher energy metabolism and rapid weight gain. This condition further elevates body heat production. If not balanced with proper management practices—such as adequate ventilation and optimal stocking density—the risk of heat stress will increase significantly.

Heat stress in poultry is defined as a condition in which chickens are unable to maintain a balance between the body heat produced and the heat released into the environment (Ahmad et al., 2022). This condition generally occurs due to an imbalance between the heat absorbed from the environment and the heat dissipated by the chicken’s body. Such imbalance can be influenced by various internal factors, such as metabolic rate, chicken species, and thermoregulatory ability, as well as external factors, including air temperature, humidity, solar radiation exposure, housing type, stocking density, and the nutritional quality of the feed consumed (Hidayat et al., 2020).

External factors such as temperature, air, and humidity are strongly influenced by Indonesia’s tropical climate, where daily temperatures can exceed 35 °C with relative humidity ranging from 70–80%. Meanwhile, the comfort zone for poultry is at a house temperature of around 25–28 °C and humidity between 60–70%. The significant difference between actual environmental conditions and the poultry comfort zone increases the risk of heat stress, especially when not accompanied by optimal house management.

Heat stress in poultry can be evaluated using the Heat Stress Index (HSI). HSI is a combined indicator used to assess the level of heat stress based on two main parameters: environmental temperature and relative humidity. This index represents the thermal conditions experienced by the livestock and serves as a reference for determining whether the rearing environment is within the comfort zone or poses a risk of heat stress. HSI is calculated by summing the values of air temperature and relative humidity (Yasa et al., 2019). The comfort zone for chickens is within an HSI range of 85 to 95. When the HSI value exceeds 95, chickens begin to experience heat stress. If the HSI value remains above 115 for an extended period, the risk of mortality in chickens increases significantly.

Poultry experiencing heat stress generally exhibit various clinical symptoms, including increased water consumption, decreased feed intake, heightened cannibalistic behavior, panting or open-mouth breathing, crouching posture with wings spread, dull appearance, closed eyes, lethargy, frequent lying down, and reduced production performance. In response to heat stress, poultry attempt to lower their body temperature through several mechanisms, such as opening their mouths, ruffling feathers, reducing feeding and movement activity, and extending resting periods (Hidayat et al., 2020).

Paracetamol has long been used in broiler chickens as an antipyretic (fever reducer), particularly during heat stress conditions in the dry season (Suriansyah et al., 2016; Palupi et al., 2015). Paracetamol, or acetaminophen, is a drug widely used in the medical field, including in animal husbandry, due to its effectiveness as an antipyretic (fever reducer) and analgesic (pain reliever) in animals. This drug works by inhibiting the cyclooxygenase-3 (COX-3) enzyme in the central nervous system, which plays a role in the synthesis of prostaglandins—compounds responsible for triggering pain and fever (Przybyla et al., 2021; Papich, 2020). By inhibiting COX-3, prostaglandin production is reduced, making paracetamol effective in alleviating symptoms of fever and pain (Freo et al., 2021; Plumb, 2018).

The use of paracetamol during heat stress conditions is permitted, but attention must be given to the drug’s pharmacokinetics in chickens, such as its half-life. The half-life of a drug is the time required for its concentration in the chicken’s body to decrease by 50% from the initial level. Understanding the drug’s half-life is essential for determining dosage, frequency of administration, and ensuring the safety of animal products for consumption after treatment (Suwandi et al., 2018). Drug residues that remain in tissues or organs after treatment can pose health risks to consumers, such as allergic reactions or contributing to antimicrobial resistance (Butzaina, 2018; Zhang et al., 2015). The half-life of paracetamol is approximately 4 to 5 hours, making this information an important reference for determining the withdrawal time before chickens are slaughtered to ensure the final products are free from harmful residues.

Based on this understanding, antipyretic (fever-reducing) drugs administered to chickens during heat stress conditions must be accurate and effective. Medion produces two effective formulations for reducing fever in poultry under heat stress conditions: Paramed-S in powder form and Paramed-C in liquid form. Paramed-S is administered via drinking water at a dosage of 1 g per 2 L of water, while Paramed-C is given at a dosage of 1 ml per 2 L of drinking water. In addition to their antipyretic (fever-reducing) effects, both products also act as analgesics (pain relievers) and support the recovery process after diseases such as Gumboro.

If poultry begin to show clinical symptoms of heat stress and the HSI value exceeds the standard threshold, it is necessary to evaluate the factors that may cause heat stress in poultry (Palupi et al., 2015). Prevention of heat stress in broiler chickens can be achieved through proper house management focused on external factors that trigger heat stress. The following are several measures that can be taken to prevent heat stress in chickens:

- Improving air circulation around chickens

Air circulation inside the poultry house plays a crucial role in influencing the internal environmental temperature (Ridho et al., 2024). Efforts to improve air circulation can be carried out through several methods, including adjusting the house curtain opening and closing system, adding fans (blowers) installed in the same direction from the front to the back of the house, and modifying physical structures such as house height, spacing between houses, and roof design. These adjustments are particularly important to apply in open house (open-type) systems. - Access to Drinking Water

Drinking water plays an essential role in supporting the metabolic processes of chickens, including body temperature regulation. Therefore, drinking water should be provided at an optimal temperature of around 20–24 °C, and not exceed 30 °C. Improving water accessibility can be achieved by increasing the number of drinkers and distributing them evenly throughout the poultry house. Additionally, it is important to maintain low water temperature by providing shade over water tanks to prevent direct sunlight exposure. Water pipe installations should also be placed in shaded areas or buried underground to prevent an increase in water temperature due to environmental heat exposure. - Cooling the Chickens’ Body

To reduce the impact of heat stress, it is important to implement effective strategies to cool the chickens’ bodies. One recommended approach is to avoid feeding during the hottest hours of the day, particularly between 11:00 a.m. and 2:00 p.m. Feeding should be carried out in three stages: in the morning at 7:00/8:00 a.m. (40%), in the afternoon after 3:00 p.m. (30%), and in the evening after 6:00 p.m. (30%). Feeding at night is considered effective because environmental temperatures begin to decrease, helping to reduce heat stress and improve feed intake. Additionally, feed can be moistened with a small amount of water supplemented with vitamins to increase palatability and nutrient intake. Another method that can be applied is creating a cooling effect inside the poultry house using a sprinkler or nozzle system installed on the roof to simulate artificial rainfall. - Adjusting Stocking Density in the Poultry House

Stocking density should be adjusted according to the type of chicken, age, and housing system used. For example, in broiler rearing within an open house system, the stocking density during the first week can reach 50–60 birds per square meter. By the fourth week, the ideal density decreases to around 7–8 birds per square meter. This adjustment is essential to maintain animal comfort, prevent heat stress, and support optimal growth and development. - Supplementation

Supplementation as a preventive measure against heat stress in poultry can be carried out through the administration of vitamins, electrolyte minerals, and micronutrients. Medion provides various supplementation products that can help support the physiological functions of chickens during heat stress conditions. These include Paramed-S, which can be administered via drinking water at a dosage of 1 g per 2 L of water, and Paramed-C, given at 1 ml per 2 L of drinking water to reduce fever caused by heat stress. Vita Stress can be administered at a dosage of 1 g per 2 L of drinking water for 7 to 10 consecutive days to prevent stress. C-Fresh can be given at a dosage of 0.5–1 g per 10 L of drinking water or 1–2 g per 10 kg of feed. Vitasel-C can be used at a dosage of 1 g per 10 L of drinking water, and Kumavit can be administered at a dosage of 1 g per 2 L of drinking water. In addition, adding premixes such as Top Mix and Mix Plus to feed can further help support chicken productivity during periods of heat stress.