Ration is the main component in the maintenance of laying hens. Ration costs are also the largest of the cost components to produce an egg. So, if the quality, amount of giving, and technique of giving are not considered by the farmer, it will cause the performance target will not be achieved and of course also cause economic losses.

Nutritional Needs Of Laying Hens

“Garbage in, garbage out” a very suitable term to describe the importance of quality raw material ration. The meaning of the term is that if the quality of raw materials used is good and meets the standards, then the resulting ration will be of good quality.

So that the performance of the chicken becomes optimal. Conversely, when the raw materials used are of poor quality, the resulting ration will also be of poor quality.

In addition to quality, quantity or amount of the term is if the quality of raw materials because although the quality is good, if feed intake or the consumption of the ration is not achieved, then the nutritional needs of the chicken will still not be met.

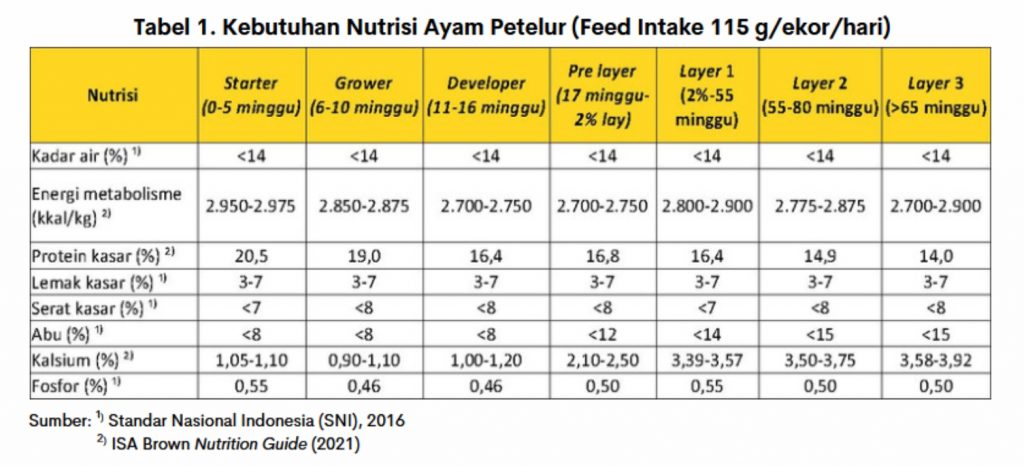

Quality rations are rations that have nutritional content in accordance with the needs of chickens. Different types of chicken also have different nutritional needs. Each phase of its growth also requires a different amount of nutrients.

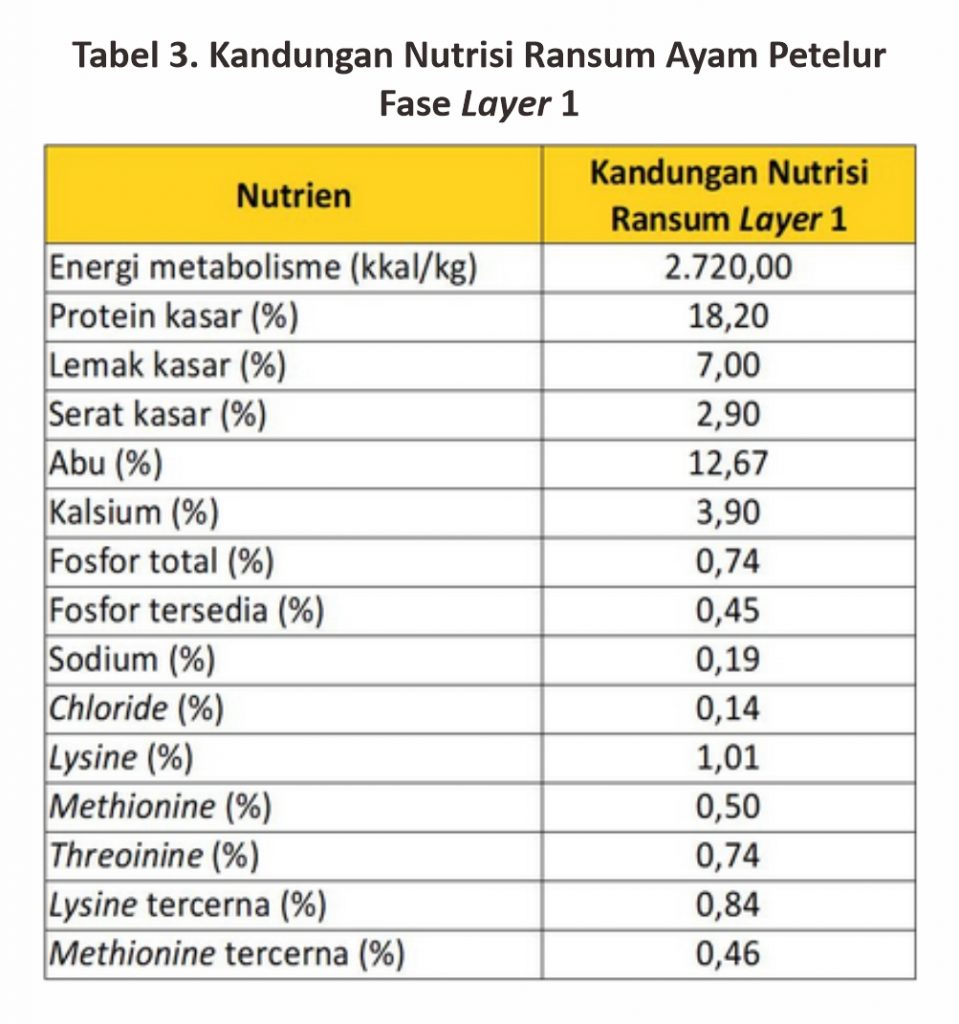

Here in Table 1. is an example of nutritional needs in laying hens ranging from Phase starter, grower, developer (grower II), pre-layer, layer 1, layer Day 2 layer 3.

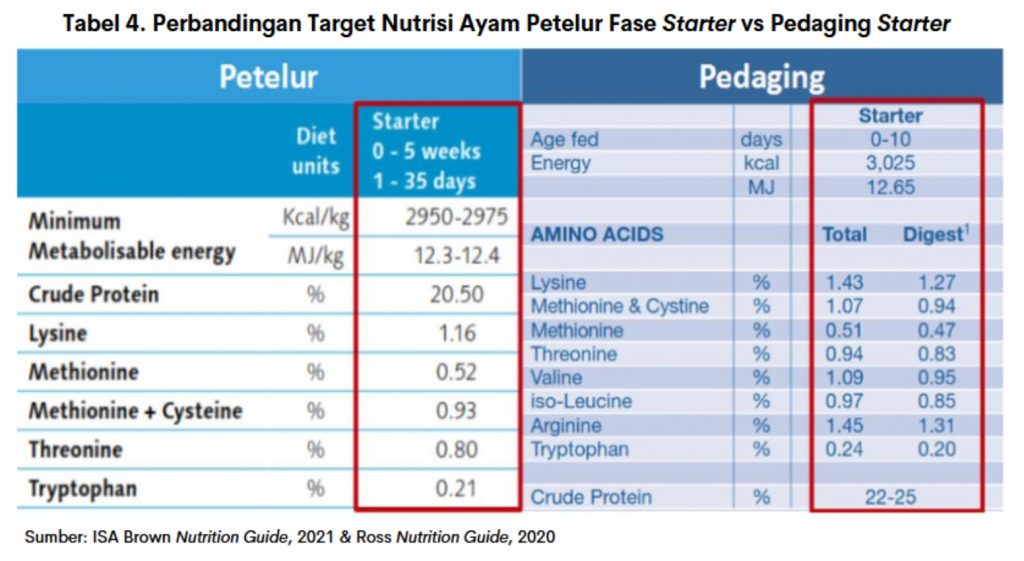

In the period chickens starter, the protein requirement is highest compared to other periods. This is because in the period starter there is a very high multiplication and growth of cells to support the formation of organs and the achievement of optimal body weight.

Continuation of the period starter is the time grower this is the time of cell development. Organs that are formed during the starter period are enlarged in accordance with the needs of the body. In this phase, cell growth will slowly stop and become a process of cell enlargement, while ration consumption continues to increase.

If the level of protein ration grower still the same as starter, then the effect is that the chicken's body will store excess protein as fat deposits, where in laying hens the excess will be stored in the reproductive tract. If this happens then the problems that arise during the layer among others, genital maturity is too early, high mortality, and a short peak production period.

While entering the spawning period (time layer), the process of cell development proceeds very slowly (so the growth of chickens is also slow, red) but the process of egg formation is just beginning. To form an egg, high protein and amino acids are needed. Therefore, the protein content of the daily ration layer will be increased, although not as high as the past starter. As for old chickens, protein is needed only for the formation of eggs, so the protein content in the ration of old chickens also decreases.

Formulation Of The Ration Of Layer Hens

The types of rations commonly used by laying hen farmers include finished rations, concentrates and self mixing (make your own ration). Ration self mixing it has been widely used by farmers, especially farmers who focus on productivity and competitiveness (price).

Self mixing it usually has the cheapest price compared to concentrate or finished rations, although occasionally the price can be more expensive due to increased raw material prices. However, in terms of the quality of the ration, the nutritional content specifications will usually be higher.

This is done as back up or safety margin on raw materials rations used by farmers. In addition, the ration self mixing more flexible or more easily adapted to the conditions of laying hens, especially from the level of feed intake (ration consumption), the variety of raw materials ration and the level of chicken production.

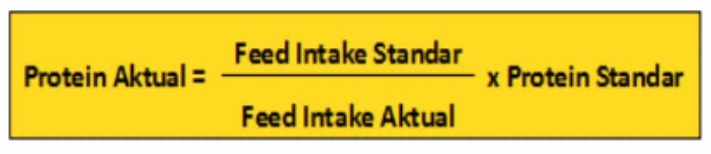

When laying hens enter the initial period of production, it is usually difficult for the ration consumption level to reach the standard (below the standard, red). One solution so that the intake of ration nutrients can meet the needs of chickens to produce eggs is to make changes to the formulation of the ration, which increases the density of nutrients.

If with target feed intake 115 g/head/Day chickens need a ration with a crude protein content of 16.4% (ISA Brown Nutrition Guide Phase Layer 1, 2021), but when the ration consumption is only reached 105 g/head/day then we can change the crude protein content to 17.96%.

By increasing crude protein levels to 17.96%, the laying hens will get the same nutritional intake as those who consume rations of 115 g/head/Day. And this becomes easier to do and apply if you use rations self mixing. The above calculation if the formula is made as follows:

1. Laying hen formulations starter

Formulation of the ration for Phase laying hens starter self mixing still not so much to apply, although it has started some farmers who have self mixing starting from the age of 1 or 10 days. When we do formulation of the ration of laying hens the starter phase needs to pay attention to the degree of digestibility of nutrients. This is because laying hens starter phase for his metabolism is not perfect. The use of enzymes should be strengthened so that the chickens are able to digest the raw materials.

The average farmer still uses rations so, in the form crumble or fine crumble. Rations from this manufacturer can be said to be rations that have been processed or cooked (heated during the stages conditioning). This process can improve the homogeneity of the ration, uniform texture of the ration and improve the digestibility of the ration. When using this finished ration, we need to monitor the stability of its physical qualities, from texture, color, smell and if necessary, chemical tests can be carried out, through MediLab.

When the performance of laying hens weight achievement phase starter this is not achieved, then immediately evaluate the achievement feed intake the day. Also check the health status, especially diseases that disrupt the digestive tract, such as coccidiosis, necrotic enteritis, colibacillosis, etc. Perlu sekiranya ditambahkan premix, seperti Mix Plus LGM13A atau Mix Plus LGM123A dengan dosis 1-5 kg/ton.

2. Laying hen formulations grower

Laying hens aged 6 weeks can already be given rations self mixing. Ration of laying hens this phase is divided into 2, namely ration grower 1 and ration developer (grower 2). Ration grower 1 is given from the age of 6-10 weeks, while the ration grower 2 is given at 11-16 weeks.

3. Laying hen formulations pre-layer

Ration of laying hens pre-layer it can be specially formulated, or use mixing between rations grower 2 with the ration of production laying hens. Ration pre-layer it serves to transition the ration grower to layer. Where is the level of calcium ration pre-layer it ranges from 2%. Ration feeding pre-layer this is 16-18 weeks.

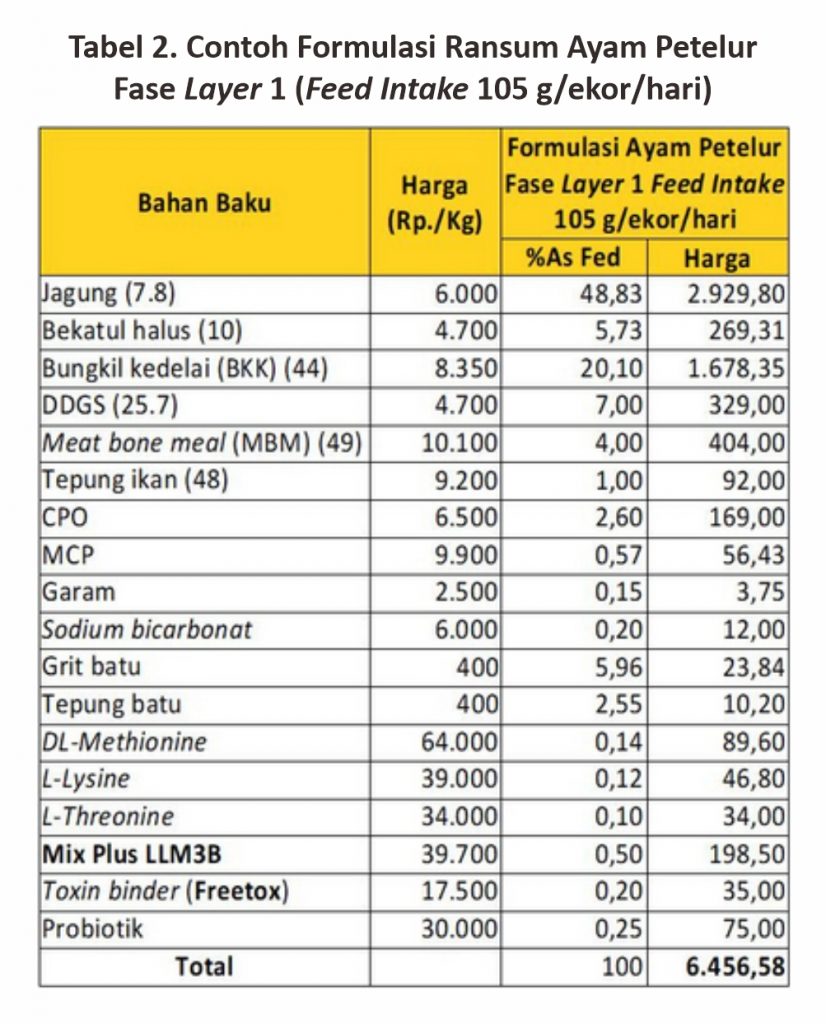

4. Laying hen formulations layer

Formulation of the ration of Phase laying hens layer willing to be placed in Cikarang feed intake- her. In addition, ration formulations for young and old laying hens (> 50 weeks) should preferably be differentiated.

Formulation of the ration of laying hens self mixing the above is an example of a formulation that has been applied by farmers. This formulation can be changed according to the conditions of each breeder. This formulation is processed using Brill Formulation System who apply the method least cost formulation (formulations with the cheapest cost).

Proper ration Management

In general, things to consider in the management of rations are:

1. Make sure the quality of the ration is appropriate

There are several requirements that can be said to be quality rations, including:

- Shape according to physiological / age of chickens

- Have high digestibility

- Attractive color and smell

- Complete nutritional content as needed

- Non-toxic

- Low antinutrients

2. Pay attention to the shape and texture of the ration given

In nature, a chicken prefers granular rations such as crumble or pellet. If during the period starter, breeders are able to provide rations in the form of crumble, but not with the period grower up to layer.

Current period grower and so on, generally farmers prefer to use rations in the form of mash/ flour for practical and cost-effective reasons.

And then there is consumption (feed intake) the chicken ration remains high according to the standard, then farmers need to consider doing beak cut (debeaking) in the age range of 8-10 weeks. With the condition of the front flat beak, the chicken can take a large amount of ration in one peck.

3. Provide ration place and drinking place in appropriate amount

Provide a sufficient number of rations and drinking places according to the number of chicken populations and place them spread evenly throughout the cage. The height at which the ration is located needs to be set so that it is parallel to the height of the chicken's back. Try not to fill the chicken ration place full, since the probability of ration splashing is high.

Ideally, it is sufficient ¾ of the capacity of the place of ration. In addition, the cleanliness of the ration and drinking place for chickens must also be maintained. Wash the place of ration and drinking water at least 2 times a day and disinfect it by soaking in a solution Medisep (15 ml per 10 liters of water) for 30 minutes every 3-4 days.

4. Give rations at a fixed hour every day

For period chickens starter give rations 4-9x a day ad libitum (always available), because in such periods the growth is very fast and the efficiency of the ration is very high.

In the period grower until layer,the frequency of rations to be 2-3x a day and need to be ensured in accordance with the standards breeder. Ration should also be carried out when the ambient temperature is comfortable for chickens. Morning can be given between 05.00-07.30, afternoon between 14.00-16.00 or night between 18.00-21.00.

In addition, try to give the amount in the morning 30-40% and evening to night 60-70%. What you need to remember is, give rations at a fixed hour every day. For example, rations are given daily 2 times at 07.00 and 15.00. Giving rations at fixed hours aims to avoid chicken stress when rations are given late.

5. Providing drinking water

Provide clean and quality drinking water ad libitum (not restricted) every day because if the consumption of drinking water is low then the consumption of rations is also low.

6. Create recording ration in full

Recording this includes recording the composition of the ration, physical condition, nutritional content, the number of exhausted rations, and the remaining rations. The ration to be given should always be weighed, so that it can be known the amount of ration that runs out. Compare the amount of chicken consumption per day with the standard manual guide, so that the performance of chickens can be monitored constantly. These data are very useful for calculating the amount of expenditure and evaluating the performance of chickens. For example, if one day consumption drops along with egg production is also down, then farmers can take action as soon as possible.

7. Perform control / checking regularly

When giving rations, try to clean the ration place and check whether it is still available or not.

In addition to general management, there are also special things that need to be considered, such as:

8. Avoid giving rations broiler for laying hens starter

In addition to the differences in nutrition targets in Table 4., the texture of the ration was different.

9. Add grit when in Phase grower

Time period grower, grit function in addition to helping digestion also serves as a source of calcium. For that, give grit containing calcium such as limestone or clamshells. For the rules of the amount of administration, at the age of 3-10 weeks give as much as 3 g/head/Week with a size of 2-3 mm, while at the age of > 10 weeks, given as much as 4-5 g/Head/week with a size of 3-5 mm.

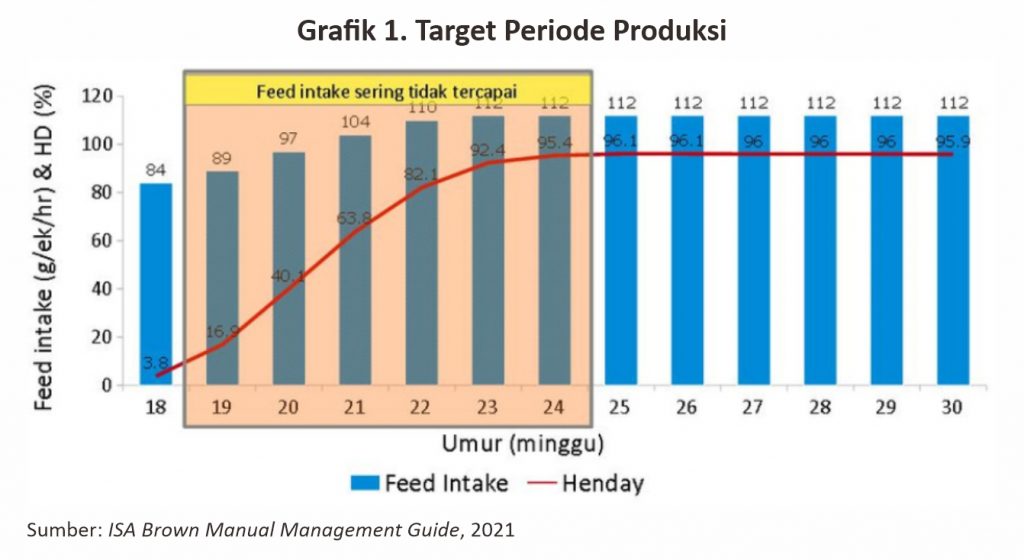

10. The peak of production must be accompanied by the peak of consumption of rations

When entering the peak period of production, of course, need to be supported also by the peak consumption of rations. Because the ration is input which must be met to produce output form of egg production. Here's an example target feed intake when entering the peak of production (graph 1.).

Importance Of Ration Quality Test

Things that must be considered in the quality control of raw materials ration that is when the raw materials come to the farm, immediately note no. batch, name supplier, date, and amount of raw material load. After that, carry out a physical and chemical quality check (if necessary). After inspection, the next raw materials stored in the warehouse rations, and sorted by no. batch as well as the date of arrival.

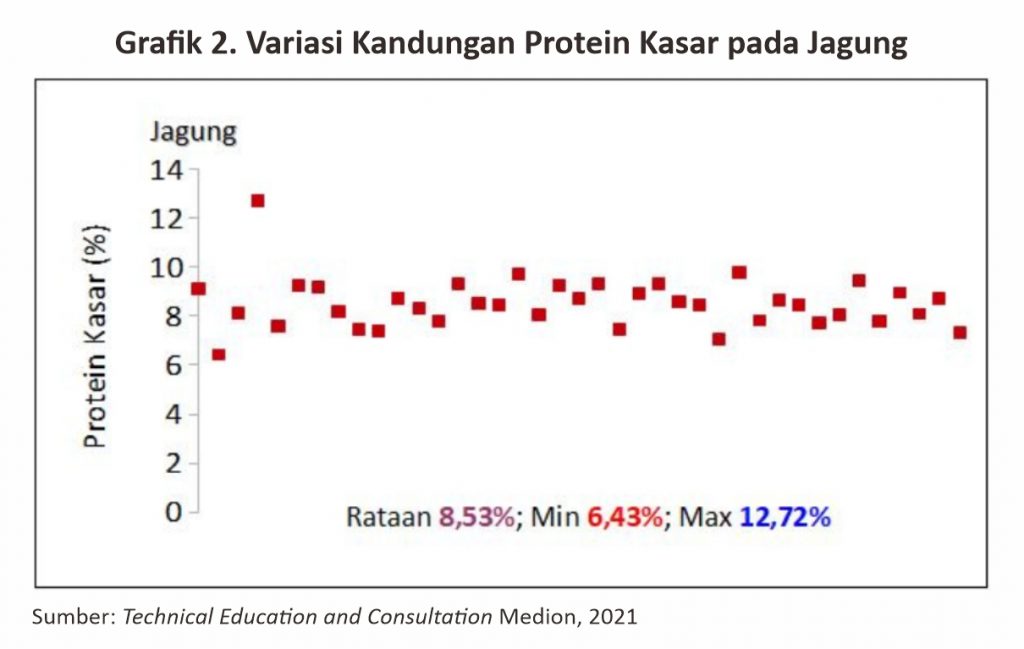

Quality control of ration raw materials is carried out routinely when ration raw materials come to the farm or when ration raw materials have been stored in the warehouse. For perishable ration raw materials such as Bran, quality control is carried out once every 1 Week. As for the raw materials that are not perishable rations can be done once every 2 weeks.

Inspection of raw materials raw ration can be done physically, chemically and microscopically. Physically, ration raw materials can be observed by the naked eye, including color, odor, particle size, and fungal contaminants. While the chemical examination of raw materials can be done by proximate tests include water content, crude protein, crude fat, crude fiber, calcium, phosphorus, and gross energy. In addition, there is also a test Phloroglucinol to test for husk contaminants found in Bran or Bran. Microscopically, the type of raw material can be observed through a microscope with a magnification of 90-500 times.

In order for the test results to be more optimal, it needs to be supported by the correct sampling and delivery techniques. Samples should be taken from several parts of the pile of raw materials or rations. The more points sampled, the more it will reflect the condition of the ration. In the delivery, the sample should not be damaged, it is better to put it in a closed cardboard box so that it is safe from contamination.

Here Is Graph 2. is an example of crude protein content data on corn that is very varied in the field. With formulations that tend to remain but raw materials like this, the reason for the need for additional premix.

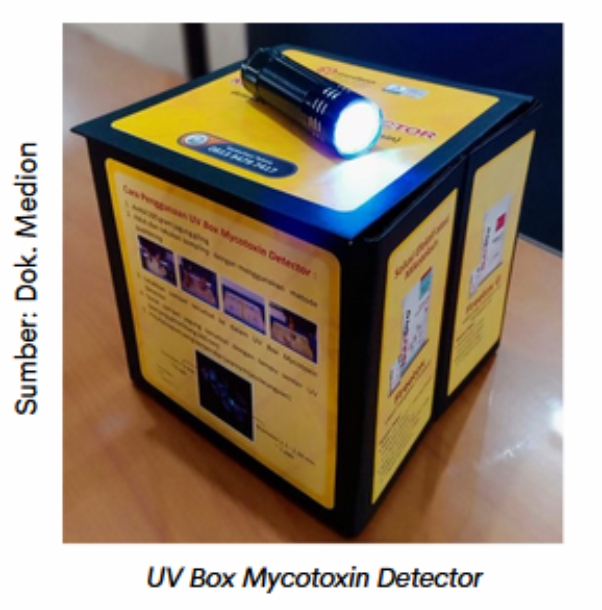

Practice Screening Mycotoxins Use UV Box Mycotoxin Detector

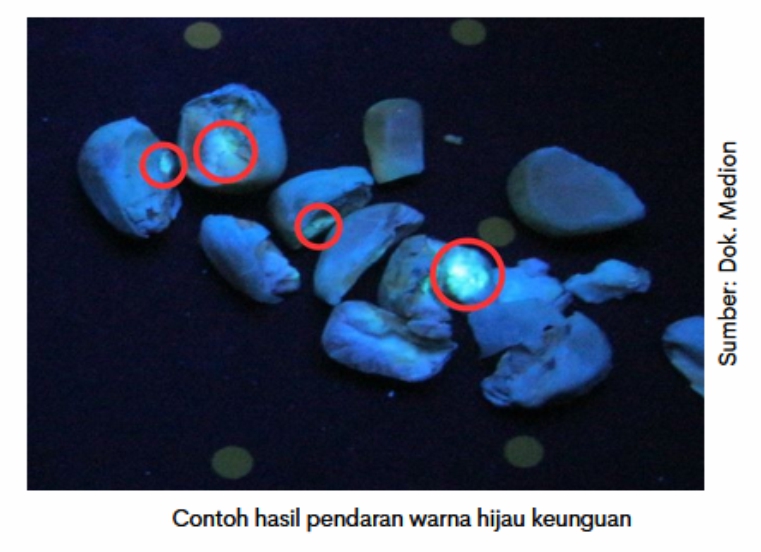

In addition to the proximate test, analysis of aflatoxin levels is also relatively often utilized. In qualitative methods, to detect the presence or absence of mycotoxins (especially aflatoxins) in raw materials such as corn, farmers can test using light UV.

The trick, corn samples are ground first, then placed in a black box and highlight with a flashlight UV. Corn that looks fluorescent (purplish green) indicates that the raw material already contains aflatoxin (see picture).

Meanwhile, in quantitative methods, farmers can test samples of raw materials or rations to MediLab to find out how many levels (ppm) of mycotoxins are in it.

The productivity of laying hens will be optimal if we pay attention to the quality, amount of feeding, and technique of feeding the ration. In addition, the cost of rations can be reduced. Greetings.