Mr. Nur Sidiq – By email

Please explain whether rice bran and pollard have the same nutritional content?. Can pollard completely replace rice bran (100%) in feed, and how does it affect the productivity of laying hens? Thank you.

Answer:

Thank you, Mr. Nur Sidiq, for your question. Rice bran and pollard are both classified as energy sources in animal feed. However, they originate from the processing of different grains. Rice bran is a by-product of the rice milling process. A grain of rice (paddy) consists of the hull, bran, endosperm (the part that becomes rice), and the germ (or embryo). To separate these components, a milling process is required. From milling paddy grains, approximately 20% hull, 6–11% bran, 2–4% rice bran, and about 60% endosperm or rice are produced (Rachmat et al., 2004). Rice bran is widely used in feed formulation as the second energy source after corn.

Meanwhile, pollard is a by-product of the wheat milling process into flour and is commonly used as an alternative energy source in animal feed. A wheat grain consists of approximately 86% endosperm, 13% bran, and 2% germ, with pollard making up about 10% of the total wheat milled into flour (Feed Reference, 2003). Based on the milling process, wheat by-products are categorized into two types: bran pollard and wheat pollard. In terms of composition, bran pollard and wheat pollard are combinations of the wheat bran and part of the endosperm (Hassan et al., 2008). However, the two are not identical. Bran pollard is obtained from the first polishing process and still contains a large portion of the outer layer, whereas wheat pollard is produced during the second polishing stage and consists mostly of the inner cuticle and aleurone layers. Physically (organoleptically), bran pollard and wheat pollard are light brown to reddish in color and have the characteristic aroma of wheat flour.

The difference in texture lies in that (a) bran pollard is coarser because it contains more of the outer wheat husk, whereas (b) wheat pollard has a finer texture as it mostly consists of the inner layers of the grain.

Nutritional Content

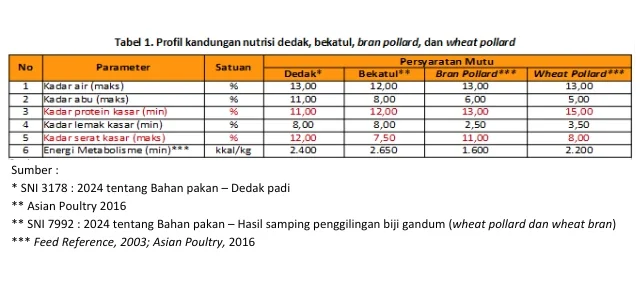

Based on quality standards, rice bran, bran, bran pollard, and wheat pollard have different nutritional profiles (Table 1). Compared to rice bran, pollard contains higher crude protein but also higher crude fiber and lower energy content.

Although pollard has a high crude protein content, it cannot completely replace rice bran (100%) in feed formulations. This is due to several limiting factors associated with pollard, as follows:

1. High Fiber Content

Based on quality standards, the maximum crude fiber content in pollard is 8%. However, in practice, many samples found in the field do not meet this standard. Tests on pollard samples analyzed at the Medion Laboratory in 2024–2025 showed varying results, ranging from 10% to 12.19%. The high fiber content is partly due to contamination with the outer husk. The outer layer of wheat is primarily composed of fibrous structures such as hemicellulose, cellulose, and lignin, which cannot be digested by chickens. Fanelli et al. (2024) stated that the high fiber content in pollard negatively affects energy digestibility.

2. Antinutritional Content

Antinutritional compounds are natural substances produced by plants as secondary metabolites that serve specific functions for the plant itself. However, these compounds are difficult to digest and can inhibit nutrient absorption in livestock. One of the main antinutritional factors present in pollard is Non-Starch Polysaccharide (NSP), primarily composed of arabinoxylan. According to Jaworski et al. (2015), the NSP content in pollard reaches 34.50%. NSP increases intestinal viscosity by binding large amounts of water, thereby affecting digesta flow rate (Makwana et al., 2022). Furthermore, this binding reduces the access of digestive enzymes to substrates, leading to decreased nutrient absorption (Morgan et al., 2022) such as fats, proteins, and carbohydrates (Silva and Smithard, 2002).

Smart Tips for Using Pollard

When using pollard as a substitute for rice bran in feed formulations, several important factors should be taken into consideration:

1. Study the Details of the Raw Materials to Be Used

It is important to first assess the quality of the pollard. The simplest way is through an organoleptic evaluation, which includes observing the smell, texture, color, and presence or absence of contaminants. If necessary, conduct a chemical analysis in a laboratory to determine the nutritional quality of the material.

2. The Formulation Must Be Balanced

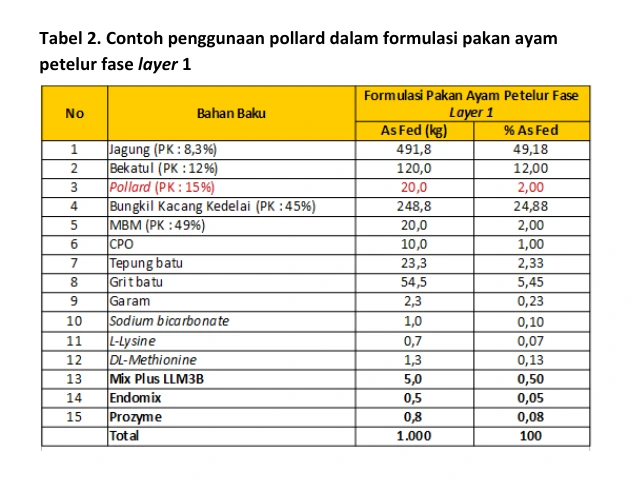

When preparing feed formulations, it is essential to maintain a balanced proportion among the raw materials, which include energy sources, protein sources, mineral sources, and premix additions, while also considering the usage limits of each ingredient. An example of pollard usage in layer chicken feed formulation can be seen in Table 2.

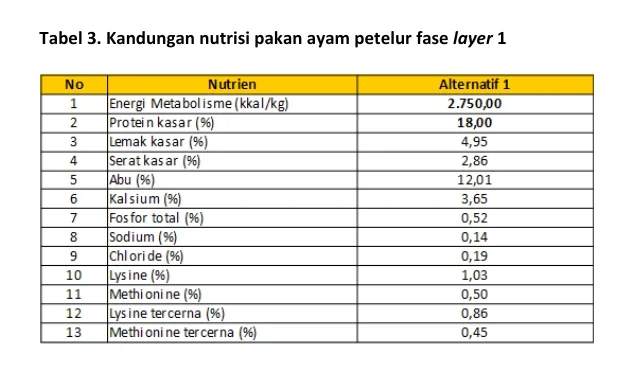

The example formulation below is based on a database of raw materials with standard quality. Field formulations may vary depending on the quality and nutrient composition of the available ingredients. Also, consider factors such as feed intake, animal status, and environmental conditions, which may influence nutritional requirements. The nutrient composition of layer chicken feed is presented in Table 3.

3. Use It Gradually

According to the literature, pollard can be included at levels of up to 15% in layer chicken feed formulations. However, it is advisable to introduce it gradually at the beginning. The initial inclusion level can be around 1–2%. After evaluating the results, the proportion can be increased in subsequent formulations as needed.

4. Add Enzymes to Improve Feed Digestibility

To optimize the digestibility of pollard, it is advisable to add NSP-degrading enzymes such as xylanase when necessary. The beneficial effect of xylanase in poultry feed is mainly related to its ability to reduce intestinal digesta viscosity by breaking down arabinoxylan in the digestive tract of chickens. Furthermore, reduced digesta viscosity in the gastrointestinal tract of broilers has been reported to improve gut function and prevent undesirable microbial fermentation, thereby contributing to better intestinal morphology, enhanced energy utilization, and improved nutrient absorption (Bedford and Apajahti, 2021; Kim et al., 2025).

Prozyme is a multi-enzyme product that contains a combination of phytase, xylanase, protease, and amylase. In addition, it includes zinc oxide and manganese sulfate, which act as enzyme cofactors to accelerate feed degradation, thereby increasing the overall enzymatic reaction rate.