The success of a livestock business is determined by four factors, namely genetics, nutrition, environment and maintenance management. The four factors are a unity that is interrelated in supporting the success of maintenance.

The reality in the field, there are still many laying hen breeders who complain about the difficulty of achieving chicken performance standards in accordance with the standards guideline each strains-her. Various problems that are commonly raised such as production does not reach the peak, production drops quickly, the weight of eggs is below standard, resulting in ration conversion that swells and ultimately disrupts the rate of income. Therefore, the focus of this article on tips to achieve maximum egg production we will describe.

Modern Laying Hens

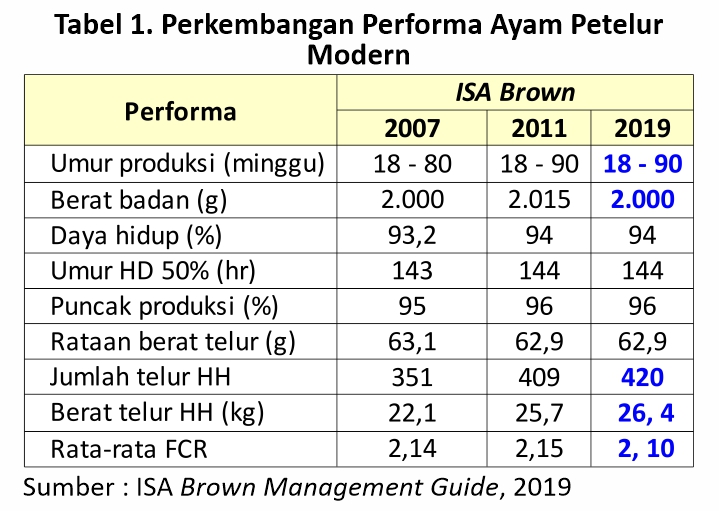

This is a list of genetically modified (genetically modified) eggs (hen day height, red) and the intensity of a long time (persistence of good egg production, red), as well as obtaining a good level of ration efficiency. Despite this, modern laying hens, as it turned out, have some drawbacks.

One of them is relatively difficult to achieve standard weight, especially when the phase starter as well as entering the beginning of production to the peak. In addition, such weight lags are difficult to compensate for during the next maintenance phase. Modern laying hens today are also more sensitive to changes in the environment and ration.

If followed by the implementation of good maintenance procedures, a laying hen is able to produce 420 eggs during one production cycle (age 18-90 weeks). This is a significant increase compared to 2007, which on average per cycle still produces 321 eggs. Likewise, the value of FCR is getting better from year to year.

Genetic changes in chickens also have an impact on the production life that can be long. Reject which is usually done at 80 weeks old, can currently be done at 90 weeks old even until some can reach 100 weeks.

The production period can be likened to a period in which farmers reap the results of maintenance pullet before. Laying hens begin to produce when they reach 18 weeks of age. At that age, the new egg production rate reached about 3.8% and will continue to increase rapidly until reaching the peak of production which is about 94-96% in a period of 2 months (at the age of 26 weeks).

Egg production is known to have reached its peak if for 5 consecutive weeks the percentage of egg production has not increased again. In accordance with the pattern of the egg-laying cycle, after reaching the peak of production, little by little the amount of production begins to decrease constantly over a long period of time (for 52-62 weeks from the first time of laying eggs). The rate of decrease in egg production normally ranges from 0.4-0.5% per week (source: ISA Brown Management Guide, 2019).

Causes Of Egg Production Problems

The main factors causing the decline in production in laying hens, among others :

1. Infectious factors (diseases)

The disease factor has long been considered one of the main causes of a decrease in egg production in laying hens. Diseases cause various organ dysfunctions, be it digestive, respiratory, nervous or reproductive organs that are directly related to egg production. Among the types of diseases that are often the topic of discussion of laying hen breeders are Newcastle Disease (ND), Avian Influenza (AI), Infectious Bronchitis (IB) and Egg Drop Syndrome (EDS).

In its development, the AI virus has 2 mechanisms in disrupting the reproductive organs of chickens, namely the damming of blood vessels in the ovaries and damage to the surface of the ovaries at the time budding exit or the exit of the virus from the cell. Both of these mechanisms will lead to a decrease and even stop egg production. AI infection also affects egg quality where the attack causes the egg to lose its pigment so that the color of the shellfish becomes paler.

Changes in the reproductive organs due to ND, namely the ovaries shrink, the egg membranes swell and bleeding occurs. Similarly, in EDs virus infection, oviduct it becomes loose and there is oedema (swelling) in its sub-serous tissue. In addition, EDS disease also causes the brown color of the egg shells to disappear, followed by thin, flabby and without shells. In the case of an IB attack, the ovaries are undeveloped, soft as Pulp, bloody, swollen and flabby.

In addition, there are frequent cases of rupture of the yolk in the abdominal cavity. Case cystic oviduct it also increases the severity of IB attacks. In terms of the quality of the eggs produced, the case of IB causes the color of the eggs to be paler, the size of the eggs is smaller, the egg whites are watery, the shells become thin and easily broken.

Damage or disruption of the reproductive system due to infection of one of the egg production-lowering diseases will result in decreased egg production. The decrease in egg production due to IB virus attacks ranged from 10-50%, eds decreased by 20-40% and AI type Low Pathogenic Avian Influenza (LPAI) can even reach 80%. While in the case of ND, the decrease in egg production both in quality and quantity even up to 60%.

In addition to viral diseases, egg production can also decrease due to bacterial diseases such as Coryza. The disease can lead to disruption of production due to the impact of the decline feed intake drastic so that indirectly lead to a decrease in egg production.

2. Non-infectious factors

In non-infectious cases there are 4 causes, including :

- Quality pullet

In the case of quality pullet which is poorly characterized by weight characteristics and uniformity pullet the low. Uniformity pullet this low can result in non-uniformity of the beginning of production and non-uniformity of the size of the eggs produced. Another characteristic is the length of time it reaches genital maturity so that the start of production becomes late. Presence pullet which has a narrow pubic bone distance and shows skeletal problems is also a distinctive feature that resulted in the chicken has a smaller egg size.

- Ration nutrition and drinking water

Poor ration quality, poor or unbalanced nutrition and rations containing toxic/antinutritional substances can cause a decrease in egg production. So it is with drinking water.

Non-fulfillment of the needs of one of the ration nutrients through ration intake, it will reduce the weight of eggs, can even result in a decrease in the amount of egg production.

Laying hens require a fairly high intake of calcium (Ca) in the production period. If the Ca preparation in the chicken's body is not sufficient, the amount of production will decrease and the formation of egg shells can be disrupted. As a result, egg shells are mushy. Ca intake also affects the color of eggshells. If Ca levels are low or insufficient then the secretion phorpyrin when painting eggshells will decrease as a result of eggshell color becomes whiter. What is also important to note in the administration of Ca and P is about the balance of their needs in the body. For Phase laying hens starter up to grower , a ratio of Ca: P of 2: 1. For the phase pre–layer the ratio is 2.5 : 1, and when the phase layer rise to 3-4: 1. If the Ca content in the ration exceeds the standard needs, it will affect the absorption of other minerals such as Mg, Mn, and Zn so that it is not optimal.

Often cases of nutritional imbalances have an impact on achieving chicken weight that does not match the standard. When entering the production period, chickens with sub-standard weight will not start egg production and if they produce, small eggs will be produced for a relatively long time.

In addition, the production period becomes backward with low production quantities. Vice versa, the growth of body weight that exceeds the standard will cause egg production to fall with a large egg size. It also often triggers cases of prolapse. The occurrence of prolapse will certainly be very fatal because it has an impact on permanent damage to the oviduct so that the chicken stops producing. The presence of fat deposits will also inhibit the process of egg formation (low egg production).

- Lack of lighting or insufficient light intensity

Laying hens that have entered the egg production period, require 16 hours of lighting (12 hours of sunlight and 4 hours of light) to maintain the amount of egg production remains optimal. Current exposure factor pullet also closely related to the achievement of weight, egg size and maturity of the reproductive tract.

- Stress factors

Stress can lead to decreased egg production. Common stressors include stress due to changes in weather/temperature (cold or panic), moving cages, parasite attacks and rough treatment. Stress caused by noise or rough treatment for example can cause the process of forming egg shells does not take place perfectly.

Cold is the most frequent stress during the rainy season. In this condition the lighting is reduced and the result is not stimulated reproductive hormones to produce eggs.

Conversely, stress due to hot weather, causing chickens to drink more and reduce the activity of ration consumption so that the nutritional needs for egg formation are not met. This condition can cause egg production to drop, as well as its quality. During hot weather, chickens will panting (gasping) so that it emits a lot of carbon dioxide (CO₂). At the formation of eggs, CO₂ is needed to form calcium carbonate (Caco₂) which is useful for arranging egg shells. As a result, the shellfish will be thinner and easier to crack.

The Key To Achieving Optimal Production

Recognizing the importance of maintenance during the critical period of raising laying hens, the following we describe some important key actions that must be carried out somewhat to achieve success from the beginning of production, among others :

1. Weight reach standard and uniformity > 85%

Body weight control (weighing of laying hens is done regularly so that the performance or growth of chickens can be monitored properly with records :

- Sample size 5-10% of the population

- Weighing on chickens aged 0-2 weeks is done per group, while for chickens aged >3 weeks is done per individual

- Use hanging scales with a dividing scale of no more than 20 g.

- At the age of 0-18 weeks weight control is carried out once every week, the age of 18 weeks to peak production is carried out every 2 weeks and after the peak of chicken production is weighed every month

- The weighing time is carried out at a fixed time, for example on Friday morning with empty cache conditions so that bias due to different times and the weight of the consumed rations can be minimized

- After the test is completed (uniformity) by comparing the chicken body weight according to the standard (+10%) with the total number of chickens weighed. The uniformity value should not be less than 85%.

2. Nutritional needs of rations and drinking water are met

Provide rations with nutrients that match the needs of chickens in each period of their maintenance, especially the content of protein, amino acids, energy, fatty acids, calcium, phosphorus, as well as vitamins D, A, E and K. Ration starter it has a high content of protein (amino acids), energy, vitamins (A, E and K) that are needed for the division of new cells.

While the ration grower has a lower content of proteins and vitamins (A, E and K) than the ration starter. This is due to the function of the ration grower to maintenance body and avoid gaining a lot of fat. For laying hens, the presence of abdominal fat (abdomen) more than 5% will reduce the performance of the chicken.

There are several things that need to be considered in giving rations to laying hens, namely :

- Rations are provided on a standard basis breeder in terms of quality and quantity in order to facilitate control and avoid wastage of rations

- Rations are provided in fresh condition by arranging the ration period and often turning over. This action will stimulate the chickens to consume rations and reduce the amount of wasted rations.

- Avoid changing rations at short notice. The pattern of ration substitution can be done by comparing the old ration with the new ration in a row 75%:25%, 50%:50%, 25%:75% and lastly is 100% new ration.

- The time of ration should be before the ambient temperature is high (when it is daytime and the sun is around the top of its orbit).

- Good ration time. Suppose the morning between the hours 03.00-08.00, afternoon hours 14.00-16.00

- Time of giving discipline rations, if often done at 07.00 then it should be given at 07.00

- Ensure the adequacy of drinking water both quality and quantity

- Do not reduce lighting during critical periods

To make up for the lack of Ca, grit (mussel shell flour) can be added to the ration. Grit is used to reserve calcium when laying hens are about to enter the egg-laying phase. Do not reduce the amount of feed when laying, especially during the beginning to the peak of production.

In addition to the administration of grit, it is also necessary to add vitamin supplements such as Strong Egg or Egg Stimulant. Egg Stimulant it is also useful to accelerate the achievement of maximum egg production while maintaining high egg production.

In addition, supplementation of amino acids (methionine and lysine), in particular those contained in Aminovit and Top Mix able to increase egg production and weight. If the quality of the ration is not good, add Top Mix to improve its quality.

3. Good health Status

To overcome the problem of declining production associated with infectious factors, in this case we must prevent disease infection through the implementation of vaccination programs and the implementation of biosecurity. To overcome cases due to infection with diseases such as ND, AI, EDS and IB, carry out vaccination programs according to local farm conditions. For laying hens that have entered the production period, you should also do monitor titer antibodi ND, AI, EDS dan IB secara rutin.

Related to health programs, ideally vaccination programs such as ND, EDS, IB, AI and korisa have been carried out no later than 2 weeks before the start of production. So that when entering a critical period there is no vaccination schedule. Revaccination is given after the peak of production and should be done with caution.

If the farmer feels that there is a decrease in egg production, immediately take an Anamnesis accompanied by readings recording production as an initial step of diagnosis. In the decline of production caused by infectious factors, the next step is to observe the clinical symptoms that appear and anatomical pathological changes that occur, as well as perform laboratory tests to confirm the diagnosis. If needed, perform serological tests by measuring chicken antibody titers to help confirm the diagnosis. These steps are important to detect early the cause of the decline in production so that further treatment can be carried out through appropriate anticipation programs.

4. Create a cozy cage atmosphere

- Build a cage with a good circulation system, choose a cage roof that is able to reduce heat or use a monitor roof system. If hot weather occurs, the provision of artificial rain or the addition of blower can be done

- The temperature felt by chickens is influenced by a combination of air temperature, humidity and airflow velocity.

- Optimal effective temperature for layer in the battery enclosure about 20-24°C with a humidity of 60-70%.

- Distance between cages at least 1 time dense cage (cage width should not be more than 7 meters)

- Set cage density

- Create comfortable conditions during the maintenance period. Open the curtains wide, install a fan, replace the wet husk, and spray the cage using a disinfectant such as Antisep or Neo Antisep.

5. Provide sufficient lighting

Lighting during the production of which serves to stimulate appetite, growth and stimulate hormone secretion Folicle Stimulating Hormone (FSH) and Luteinizing Hormone (LH) which plays a role in the formation of egg yolk and ovulation (release of the yolk).

Set the lighting program. To obtain eggs of optimal size, do not give additional light to chickens grower before the chicken reaches a weight between 1,550-1,600 g (ready for production). Make sure the lights are spread evenly throughout the room, because the uneven distribution of lights can cause light stimulation between chickens to be unequal and have an impact on egg production in one cage that is not uniform.

Lighting can be used to regulate when the chicken enters the production period.

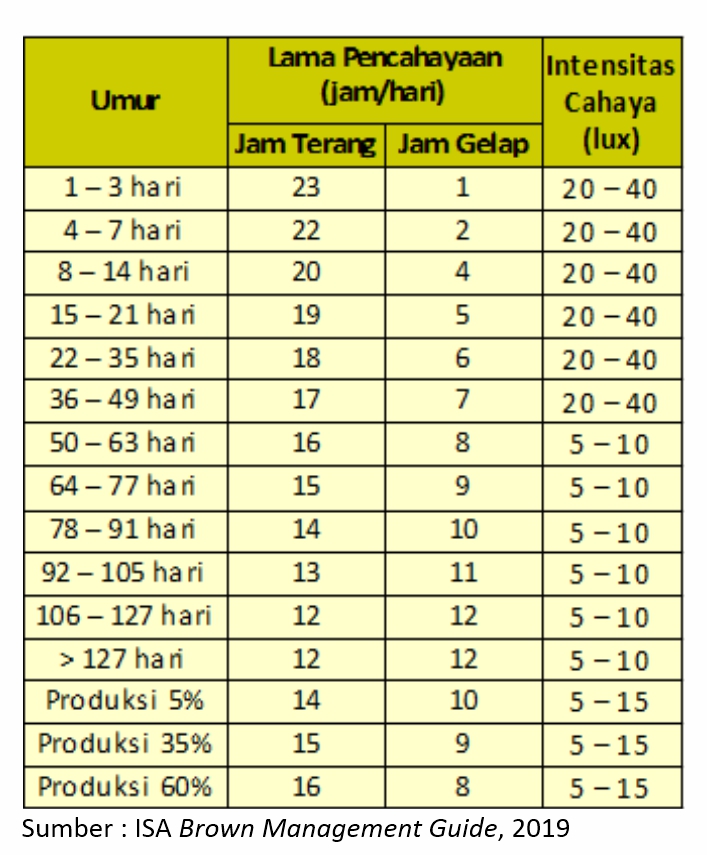

- Time starter (0-6 weeks), at this time the intensity of lighting takes the longest time, especially when brooding (21-24 hours) with an intensity of 20-40 lux. The goal is for the chicken to recognize the place of ration and be stimulated to eat

- Time grower (7-18 weeks), lighting is given in a short time (12 hours/only from sunlight) with an intensity of 5-10 lux. The goal is to control the development of the reproductive organs and achieve optimal body weight when starting production. If at this time given excessive light will cause chickens to lay eggs early or chicken weight exceeds the standard (increase the risk of prolapse)

- Time layer (>18 weeks-reject), light is given a maximum of 16 hours with an intensity of 10-20 lux. The addition of lighting duration should be done immediately when the chicken first lays eggs, the next addition is done gradually (increasing ½ hour every week from the first egg laying until it reaches 16 hours). Another important thing is not to reduce the length of exposure when chickens produce, especially during the critical period (age 18-25 weeks).

As a guide, the following appendix to lighting programs that can be applied in laying hen farms:

6. Evaluation with recording

Creating a table containing data on the state of livestock per cage must also be done by farmers. Recording table (recording) it contains parameters that can be used as a benchmark for maintenance evaluation. In the making, recording could include :

- Population (number of chickens and percent of deaths)

- Ration consumption (kg ration / head and total ration)

- Cage activities (vaccination and treatment program)

- Cage conditions (temperature, humidity, temperature and wind speed)

- Daily FCR as well as weekly weight and percent diversity.

The key to the success of the laying hen farming business lies in good management so that the achievement of maximum performance targets can be achieved. Greetings.