The poultry industry is one of the main pillars of affordable animal protein providers for the people of Indonesia. In recent years, the sector has faced increasingly complex dynamics, ranging from price fluctuations, changes in consumption patterns, to ever-increasing production cost pressures. Among the various cost components, feed occupies the largest share reaching more than 70% of the total cost of production. Therefore, the dynamics of feed both in terms of raw materials, price, quality, and availability have a direct impact on farmers. According to the combined livestock food company (GPMT) in 2025, poultry feed production is good broiler and layer projected to increase 2-3% compared to the previous year. This is a picture that the development of poultry sector is increasing. However, there are also many challenges faced by farmers during 2025, including nutritional quality and varying raw material prices.

Review of the quality of raw materials and feed in 2025

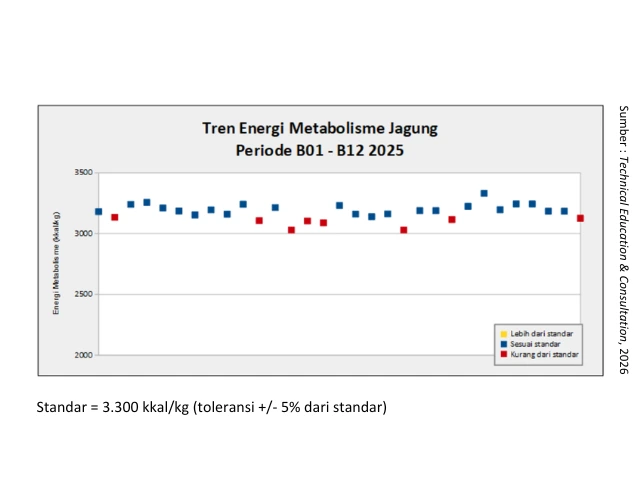

Corn is one of the main raw materials in the formulation of animal feed, especially as an energy source. The quality of corn largely determines the nutritional value of the final feed, in particular the parameters of metabolic energy (EM). Based on the test results entered in the Medion laboratory during 2025, the energy value of corn metabolism in general is in the range of 3,000 – 3,300 kcal/kg. The majority of samples showed values in accordance with the standard of >= 3,350 kcal/kg with a tolerance of +/- 5%. This reflects that the quality of corn raw materials received is relatively stable and can support the needs of feed formulation consistently. Nonetheless, there are still found metabolic energy values that are below the standard. Some samples with significant energy values were substandard, reaching even a fairly low range (1,700 – 2,800 kcal/kg). This condition can be related to seasonal factors, such as increased moisture content of corn due to weather conditions, as well as the potential for quality degradation during storage and distribution.

Parameter yang tidak kalah penting untuk diperhatikan berkaitan dengan kualitas bahan baku (jagung) adalah ada tidaknya kontaminasi mikotoksin (racun jamur). Mikotoksin merupakan senyawa toksin yang sangat stabil, sekali diproduksi maka sangat sulit untuk dihilangkan, bahkan dengan proses pemanasan pada suhu tinggi. Hanya waktu 6 jam saja, jamur sudah bisa tumbuh dan menghasilkan toksin. Mikotoksin juga mempunyai sifat akumulatif di dalam tubuh ternak, sehingga dalam jangka panjang akan menimbulkan efek negatif pada ternak. Fang dan Broomhead (2014) menyatakan bahwa lebih dari 400 jenis mikotoksin telah teridentifikasi, namun yang paling sering menyerang unggas adalah aflatoksin, fumonisin, okratoksin, deoksinivalenol, T-2 toksin dan zearalenone. Berdasarkan data uji, tren kontaminasi aflatoksin baik di jagung dan pakan di Indonesia mencapai 42,86% berada di atas standar. Mikotoksin umumnya akan muncul pada bulan-bulan dengan intensitas hujan yang tinggi yang menyebabkan kadar air pada bahan baku meningkat dan pengeringan sinar matahari tidak optimal. Sehingga memicu pertumbuhan jamur yang akan menghasilkan metabolit sekunder yaitu mikotoksin. Namun, fakta di lapang, mikotoksin juga muncul pada bulan-bulan dengan intensitas hujan yang rendah. Sehingga menjadi penting untuk diperhatikan terkait manajemen penyimpanan di gudang dan bila perlu tambahkan mold inhibitor or additive penghambat pertumbuhan jamur, seperti Fungitox, yang memiliki fungsi ganda sebagai mold inhibitor and toxn binder.

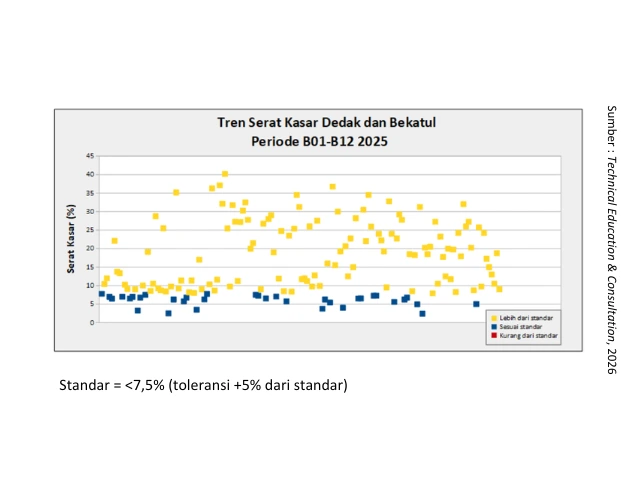

In addition to the trend in the nutritional quality of corn, the quality of Bran also needs to be considered. One of them is coarse fiber content. Based on the test results during 2025, the crude fiber content of Bran showed a fairly wide variation, ranging from a low range to values that exceed the standard. The Data showed that most of the samples (77.56%) were more than the maximum standard of 7.5%. The high level of coarse fiber in Bran can be triggered by several things such as processing and indications of husk contamination. This condition will affect the content of other nutrients such as crude protein, metabolic energy, and can reduce the digestibility of feed.

Review Of Raw Material Prices In 2025

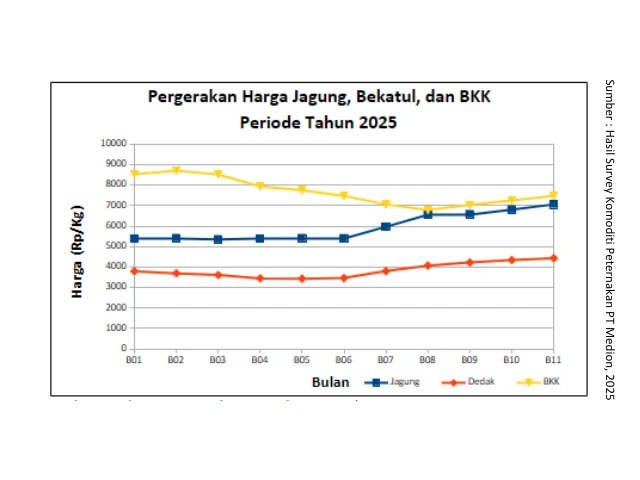

Dalam beberapa bulan terakhir, harga bahan baku pakan ternak, khususnya jagung dan bekatul mengalami peningkatan yang cukup signifikan. Berdasarkan data hasil survey PT Medion dan laporan pembelian pakan jagung nasional (Ditjen PKH 2025), harga jagung dan bekatul mencapai harga tertinggi di Rp 7.000 per kg dan untuk bekatul di beberapa daerah ada yang mencapai Rp. 4.800 – 5.000 per kg. Menurut data GMPT 2025, tren harga jagung 2025 terus meningkat polanya seperti tahun 2023. Meskipun data trend harga BPAT impor mengalami penurunan tetapi dengan asumsi komposisi bahan pakan jagung mencapai 50% dalam formulasi dan 50% bahan lain harga nya stabil, maka dengan kenaikan harga jagung Rp. 500/kg akan meningkatkan harga pakan hingga Rp. 250/kg. Kenaikan harga jagung dipengaruhi oleh beberapa faktor, antara lain tingginya permintaan baik dari peternak maupun industri pakan dan kebijakan pemerintah dalam menarik hasil panen untuk mempertahankan harga jagung di tingkat petani. Selain jagung, harga bekatul juga menunjukkan kenaikan seiring meningkatnya permintaan dan terbatasnya ketersediaan bahan baku dari penggilingan padi. Sementara itu, bahan baku sumber protein seperti Bungkil kacang kedelai (BKK), sempat mengalami tren penurunan harga sampai di Rp. 6.500/kg, bahkan dibeberapa daerah ada yang mencapai di angka Rp. 6.300/kg. Tingginya harga bahan baku utama, menyebabkan para peternak beralih dengan bahan pakan alternatif dengan tujuan untuk menekan biaya produksi. Beberapa bahan baku alternatif yang mulai banyak digunakan seperti pollard, wafer waste, and biscuits. However, this alternative raw material cannot replace 100% of the main raw material, so it is necessary to be wise in using these alternative raw materials.

Impact Of Raw Material Quality Variation

Variations in the quality of raw materials have a direct impact on livestock productivity. Some impacts that can arise due to differences in the quality of raw materials:

1. Decline in production

The quality of nutrition is closely related to the adequacy of the needs of chickens for both basic living and production. Some nutrients are very influential such as crude protein, crude fiber, metabolic energy, calcium, and phosphorus. Metabolic energy levels are less, will cause a decrease in the production of meat / eggs due to metabolic energy will be used for basic living (activity, maintaining body temperature balance) so that the energy for production is not sufficient. Feed reformulation needs to be done to meet the nutritional needs of livestock and there needs to be the addition of other energy source feed ingredients to meet the nutritional needs of livestock to be balanced, for example CPO, wheat, sorghum, etc.

In addition, too high coarse fibers in raw materials can lead to a decrease feed intake, decreased digestibility, bound minerals Ca, P and the occurrence of wet drooping. So its use needs to be limited. It is necessary to reformulate feed to meet the nutritional needs of livestock. In addition, high fiber levels are usually correlated with high levels of phytic acid, which has an impact on The Binding of amino acids and minerals, especially phosphorus. This binding causes the availability in the body of livestock to be low and has an impact on productivity. To break the bonds of phytic acid it is necessary to add phytase enzymes such as Betterzym (Dosage 0.60 kg per ton of feed)/Prozyme (Dose of 0.75 kg per ton of feed) to improve the digestibility and utilization of nutrients, especially phosphorus (P).

High crude fiber is also generally correlated with low crude protein in raw materials. Low crude Protein can interfere with growth, development, and egg production. It is also an indication of an imbalance of amino acids needed by livestock.

2. Decreased egg quality

Mycotoxin contamination of raw materials also negatively affects productivity, one of which is the quality of eggs produced. Mycotoxins such as aflatoxins cause damage to some organs such as the liver, gizzard, and kidneys. Damage to the liver causes a decrease in the metabolic process of proteins, carbohydrates, fats, and minerals such as calcium phosphorus in the body of livestock, causing thin egg shells. It also reduces the immune system (immunosupressive). Aflatoxin contamination can cause Lazy Leucosite Syndromedisease, in which lymphocyte cells as the main bulwark in the fight against the source of the disease from outside the body does not provide an optimal immune response. Reproductive disorders such as zearalenone are estrogenic, mimicking natural reproductive hormones. This is due to the fact that there is an abnormal formation of ovarian follicles and egg production (double yolk) or there is no ovulation at all.

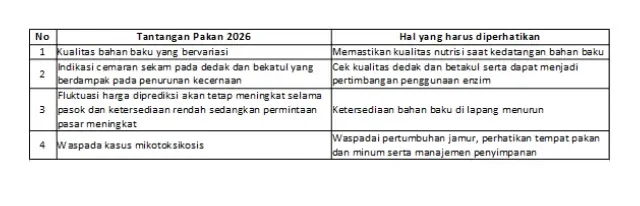

Feed Challenge Prediction 2026

In general, it is likely that some variation in the quality of raw materials that will be found in 2026 will be relatively the same as the quality of raw materials in previous years. The emergence of mycotoxin cases is also predicted to continue to appear both in raw materials and in feed. This is related to fluctuating weather conditions and poor management of feed storage.

Wise steps in facing feed challenges

Strategic steps to be taken on farms by 2026 to face feed challenges :

1. The quality of the raw material is determined by the quality of the raw material and the quality of the raw material is determined by the quality of the raw material and the quality of the raw material is determined by the quality of the raw material and the quality of the raw material (Medion Laboratories). Recommendations for the right test time : on arrival, change of season, and change of supplier.

2. When using alternative raw materials, first get to know the details of the raw materials and their characteristics. Use gradually from 1% while evaluated against performance and can be increased to 5% Use. Add enzymes Prozyme to improve the digestibility of feed.

3. Feed storage areas need to be kept in clean conditions, ensuring that there is no crust on the feed gutter that can be a place for fungal growth.

4. Feeding management is also carried out gradually to minimize stress on chickens. Do it monitor against the consumption of feed and feed flipping periodically to increase appetite.

5. Add mold inhibitor Fungitox to inhibit the growth of fungi. And no less important when humid conditions, especially during the rainy season, you should use toxin Freetox or Freetox G to bind mycotoxins in feed. to increase appetite.

6. Also provide premix supplementation such as Mix Plus to optimize productivity.

banyak, presisi, dan seragam. Sehingga kapasitas mengikat mikotoksin

semakin banyak

Feed management is one of the crucial aspects that support the success of the livestock sector. Challenges and opportunities must be appropriately anticipated. By knowing the feed projection in the coming year, it is expected to be a common concern. Such is the review and projection of feed in 2025 – 2026. May be useful.